High repetition frequency narrow pulse width semiconductor pumping green laser

A high repetition frequency, semiconductor technology, applied in the field of lasers, can solve the problems of outputting two green beams, wide pulse width, pulse tailing, etc., and achieve the effect of strong environmental adaptability, narrow pulse width and high repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

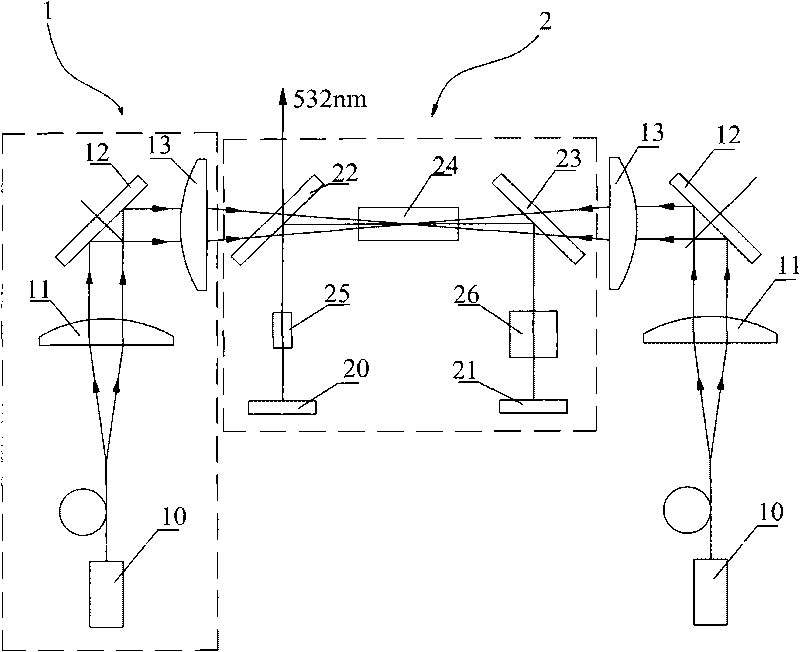

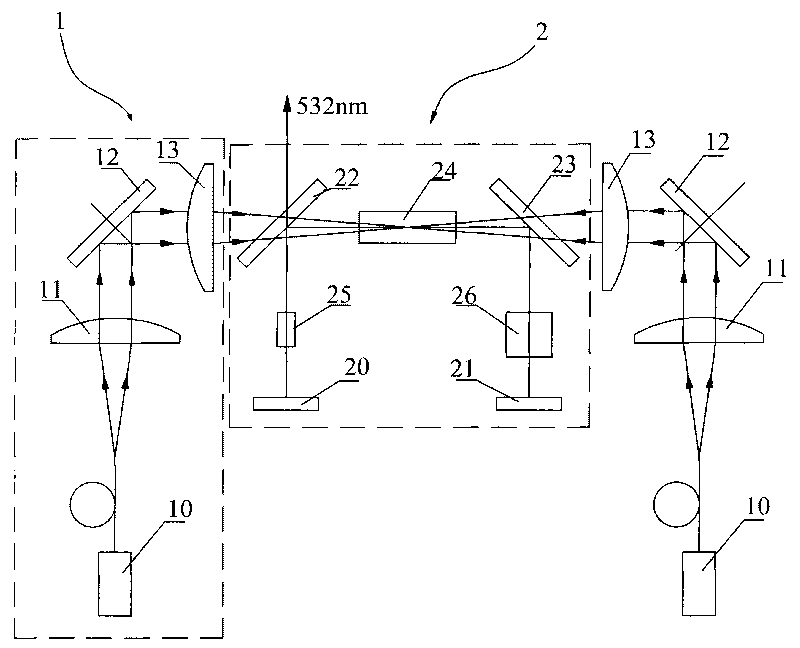

[0012] The structural features and attainable effects of the present invention will now be described in detail as follows in conjunction with the accompanying drawings and specific embodiments.

[0013] The high repetition frequency and narrow pulse width semiconductor pump green laser of the present invention is used to generate green light, which includes two sets of pump coupling focusing systems 1 and a resonant cavity 2, and the two sets of pump coupling focusing systems 1 are respectively located in the resonant cavity 2 The two ends of the two ends, and the pump light emitted by the pump coupling focusing system 1 enters the laser working material in the resonant cavity 2 with double-end surface pumping. The pump coupling focusing system 1 includes a pump light source 10, a plano-convex collimating mirror 11, a plano-convex mirror 12 and a plano-convex focusing mirror 13, wherein the plano-convex collimating mirror 11 and the plano-convex focusing mirror 13 are lenses, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com