Electric machine comprising a superconducting rotor winding

A superconducting rotor and rotor winding technology, applied in the field of motors, can solve problems such as expensive working gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

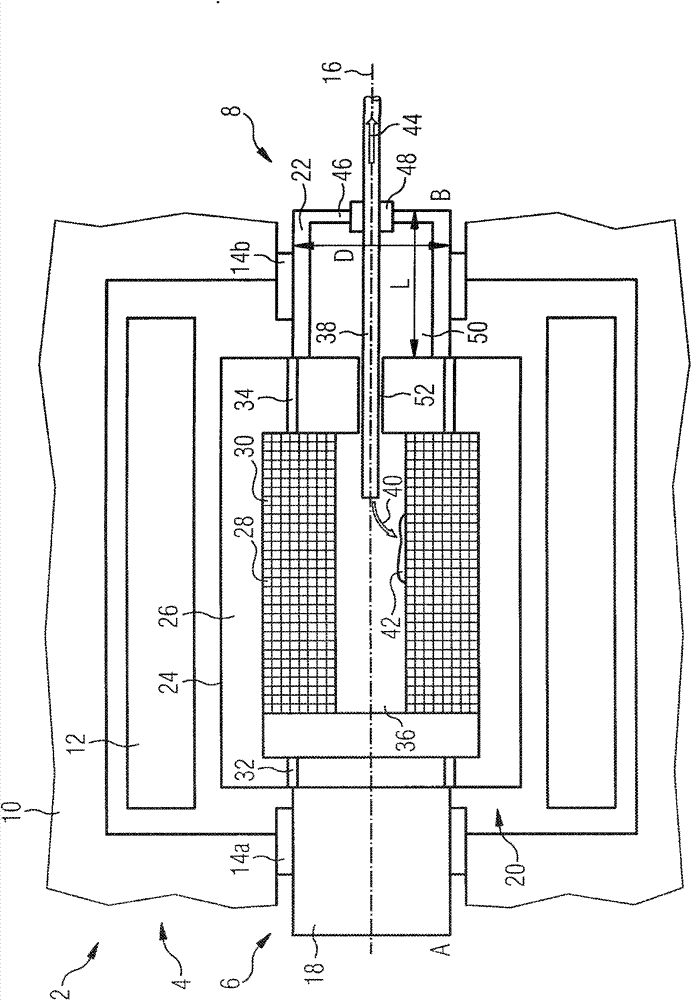

[0026] figure 1 Shown is an electric motor 2 as an example of an electric motor comprising a stator 4 , a rotor 6 and a cooling system 8 acting on the rotor 6 .

[0027] The stator 4 comprises a stationary stator housing 10 in which a stator winding 12 is fixedly anchored. A bearing 14 a , 14 b arranged in the stator housing 10 , in which the rotor 6 is mounted rotatably about its central longitudinal axis 16 , is fastened on the A side A and the B side B of the electric motor 2 .

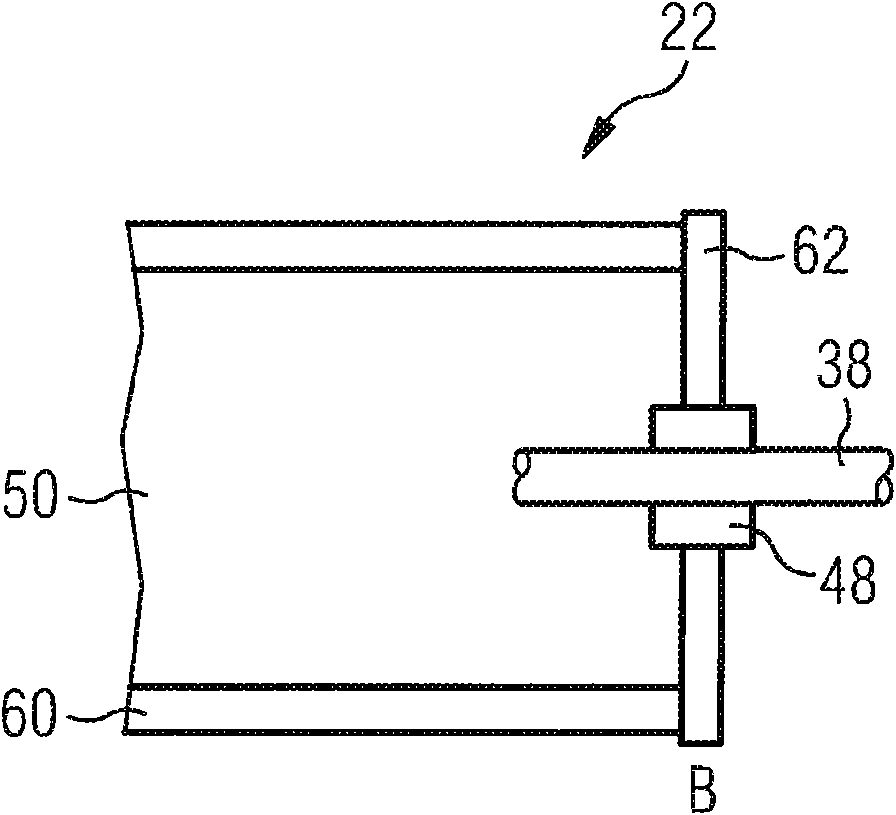

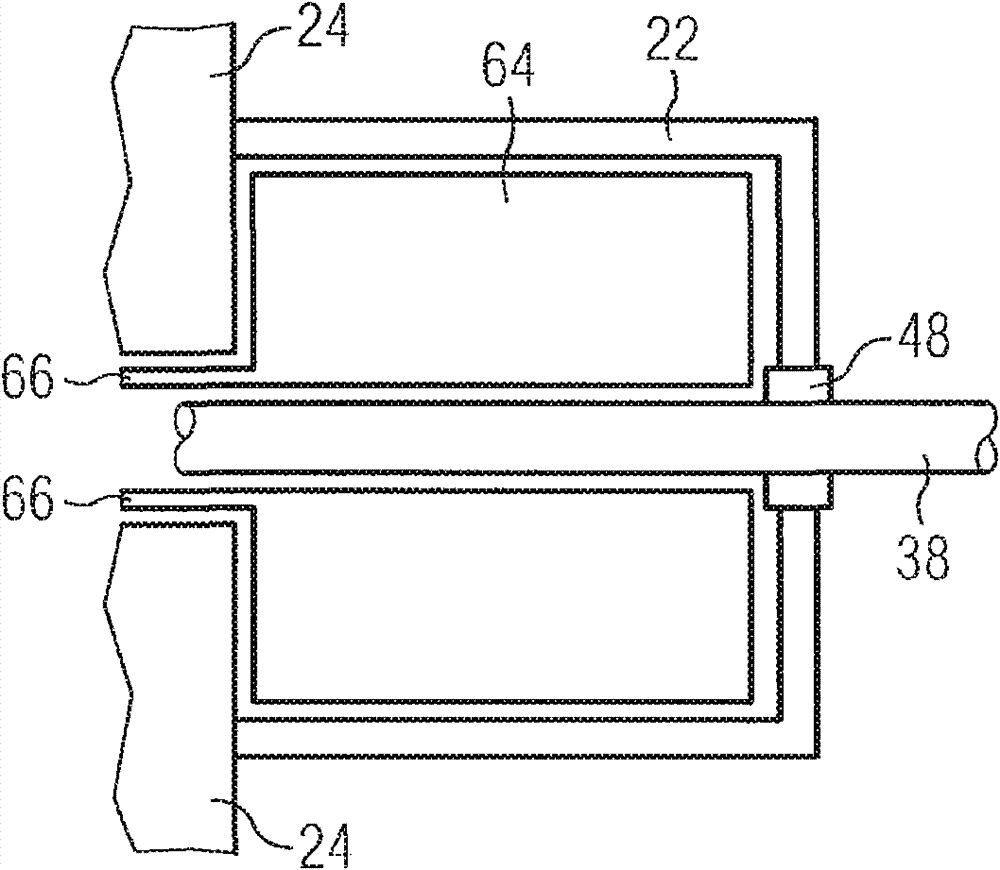

[0028] On the A side, the rotor 6 comprises an AS shaft 18 fixed in a bearing 14 a for transmitting the torque generated by the electric motor 2 . The rotor 6 generally has three parts arranged in series in the axial direction. A core component 20 inside the motor 2 is connected to the AS shaft 18 , and the core component is not only fixedly connected to the AS shaft 18 but also fixedly connected to the BS shaft 22 . The BS shaft 22 is fixed in a bearing 14b inside the stator 4 .

[0029] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com