Method and device for recovering liquid crystal in waste panel

A technology for panels and liquid crystals, which is applied in the field of recycling liquid crystals in discarded panels, can solve the problems of changing liquid crystal formulations, complicated processing steps, and inability to apply directly, and achieves the effect of reducing complexity and simplifying purification steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

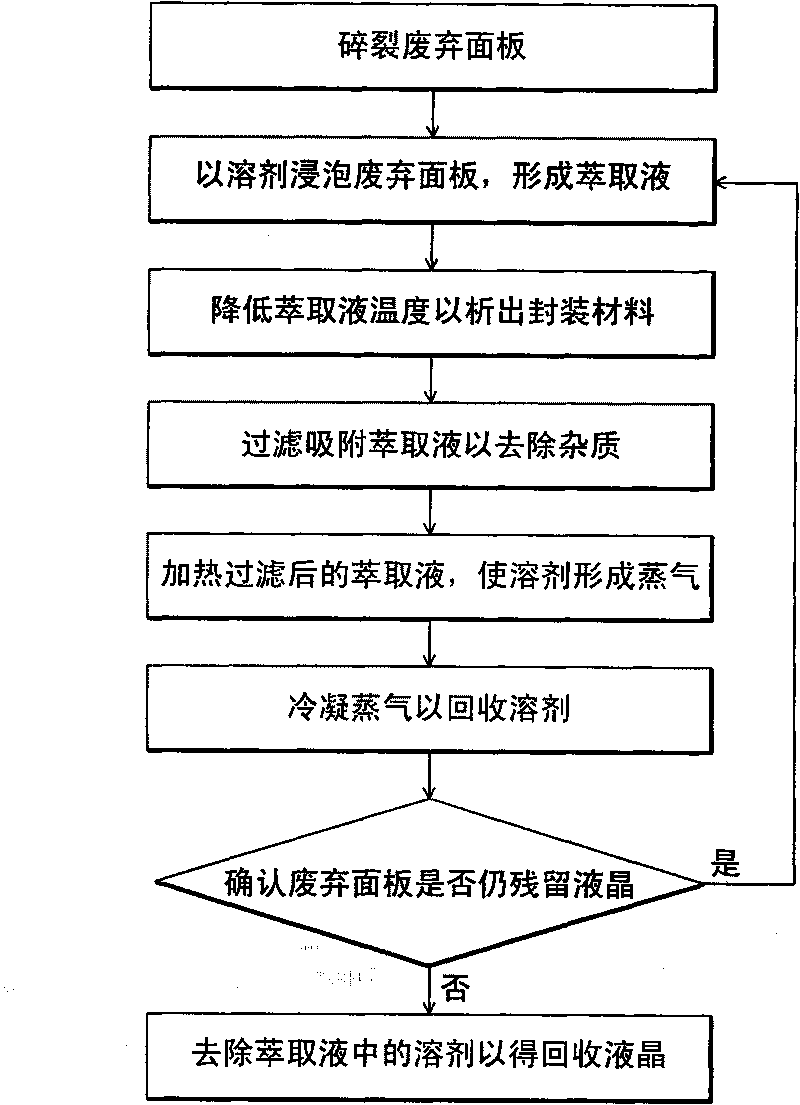

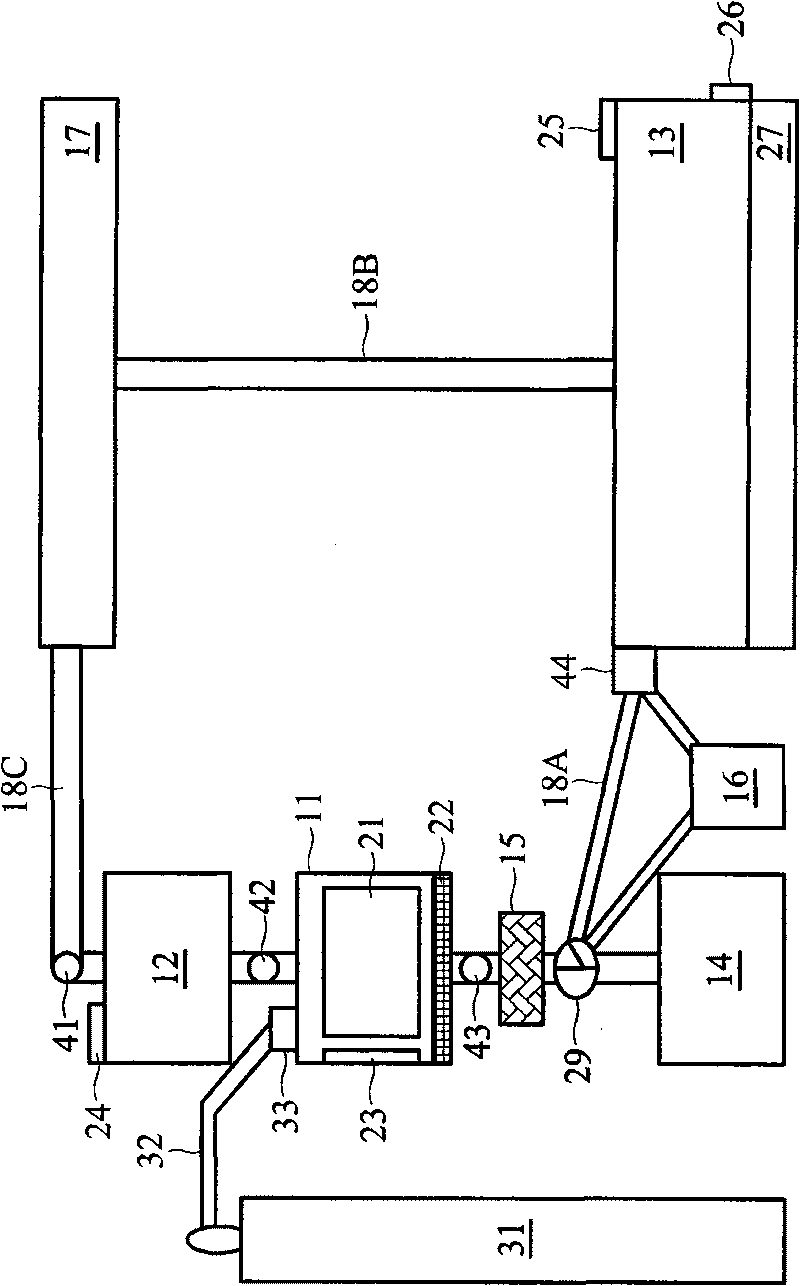

[0049] Get 21 pieces of discarded panels at 15 o'clock in a certain factory. The liquid crystal used in it is twisted nematic (TN-Q1 for short). After fragmentation, acetone is used as the extraction solvent. figure 1 ) and device recovery liquid crystal (please refer to figure 2 ). It should be noted that the recovery device in Example 1 does not contain a temperature control device and a filter adsorption device 15 . First, a 1000 mL broken panel is placed in the 2000 mL extraction tank 21 . Then take 3000mL of acetone as the extraction solvent and put it into the storage tank 12, then open the switch valve 42 to let the solvent flow into the extraction tank 11, and soak the broken panel for 30 minutes to form an extraction liquid. Then the extract is filtered through the filter plate 22 and then flows to the collection tank 13, and the collection tank 13 is heated with a water bath at 90° C. to make the acetone in the extract form vapor. The acetone vapor is condensed b...

Embodiment 2

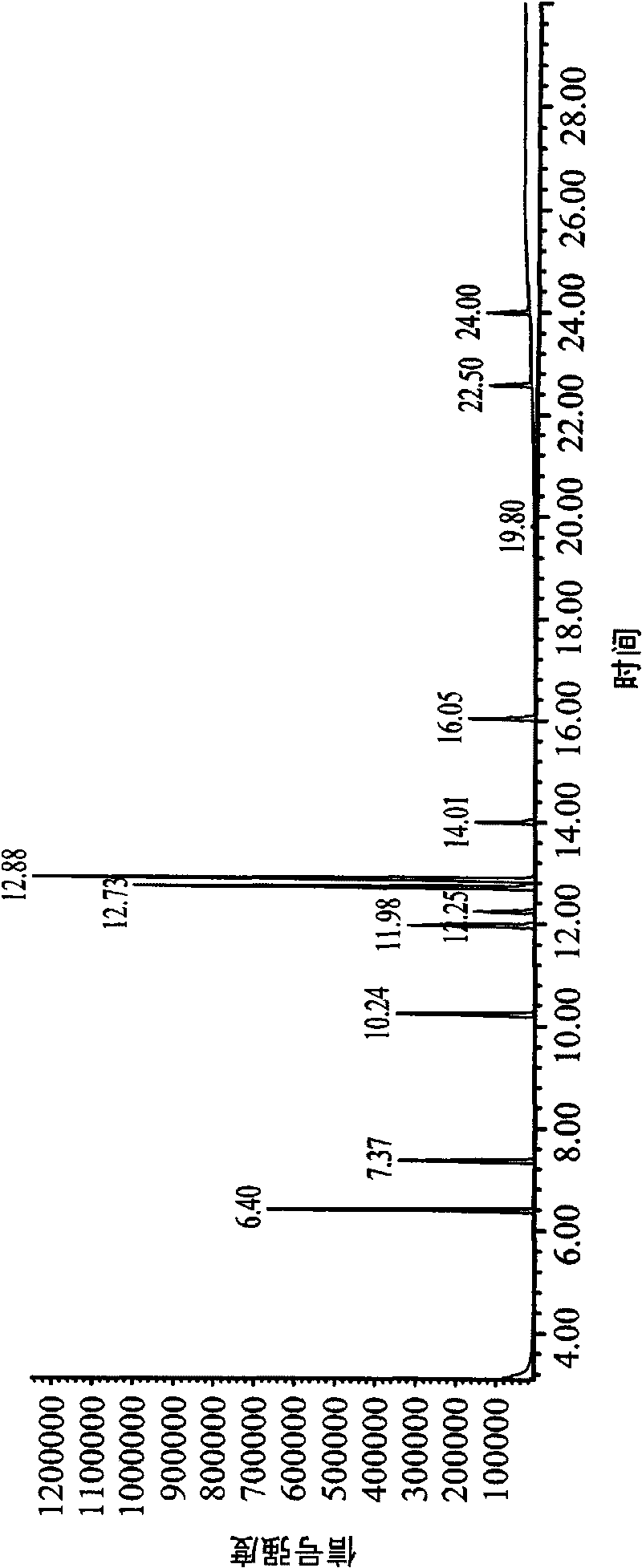

[0053] Similar to Example 1, the difference is that the extraction solvent is changed from acetone to n-hexane, the temperature of the water bath in the collection tank 13 is 85°C, and a temperature control device is installed in the extraction tank 11, between the collection tank 13 and the extraction tank 11 Set up filter adsorption device 15. Its GCMS spectrum is as Figure 6 shown. Depend on Figure 6 and image 3 It can be seen from the comparison that the composition of the recovered liquid crystal in Example 2 is very similar to that of the original liquid crystal.

Embodiment 3

[0055] Get 76 discarded panels at 32 o'clock in a certain factory. The liquid crystal used in it is a vertical alignment type (VA-C1 for short). After fragmentation, normal hexane is used as an extraction solvent. figure 1 shown) and devices (such as figure 2 Shown) to recover liquid crystals, first place a 20L broken panel in a 30L extraction tank. Then take 40L of n-hexane as the extraction solvent and add it to the storage tank, then make the extraction solvent flow into the extraction tank, and soak the broken panel for 30 minutes to form an extraction liquid. Then the extract is temperature-controlled, filtered and adsorbed, and the extract flows to the collection tank, and the collection tank is heated with a 90°C water bath to make the n-hexane in the extract form vapor. Use the condensing device to condense the n-hexane vapor to form liquid droplets and flow into the storage tank. After the extract in the extraction tank completely flows into the collection tank, let...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com