Casting mould for high-pressure switch transitional coupling bus bar canister

A transitional connection and casting mold technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of huge production costs and the inability to realize the relative curve movement of the movable mold and the fixed mold in the casting mold, so as to save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

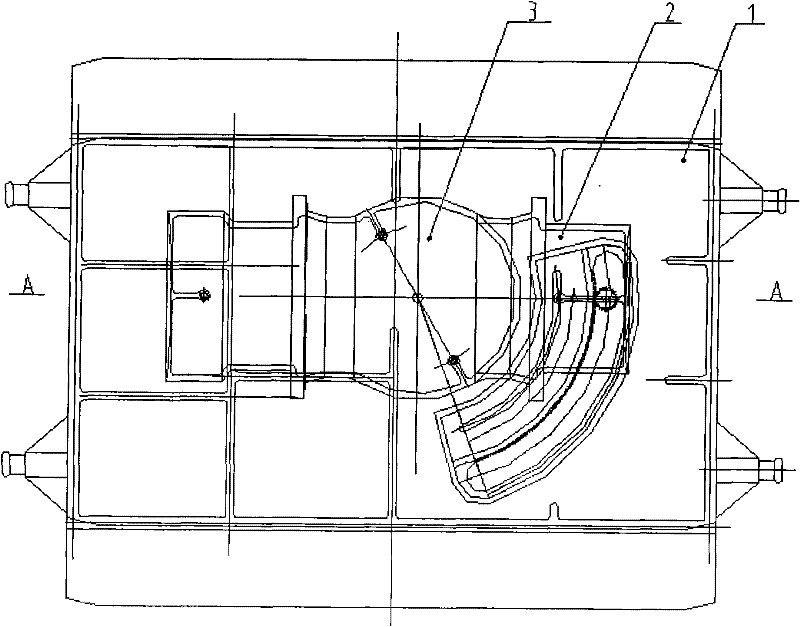

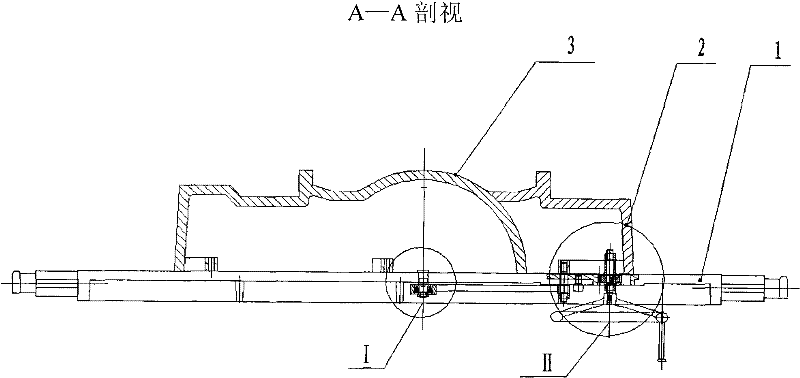

[0022] Such as figure 1 As shown, the high-voltage switch transition connection busbar barrel casting mold includes two upper and lower templates with symmetrical structures. Form the shape of a sphere sandwiched between two cylinders. The cylinder part is provided with a flange structure. The hemisphere of each template and the half cylinder on one side are fixed, which is a fixed pattern 3, and the half cylinder on the other side It is movable, and it is a moving pattern 2. The moving pattern takes the center of the sphere of the fixed pattern as the center, takes the parting surface as the rotation plane, and rotates horizontally in the rotation plane. The moving pattern 2 rotates around the fixed pattern 3 through a gear mechanism.

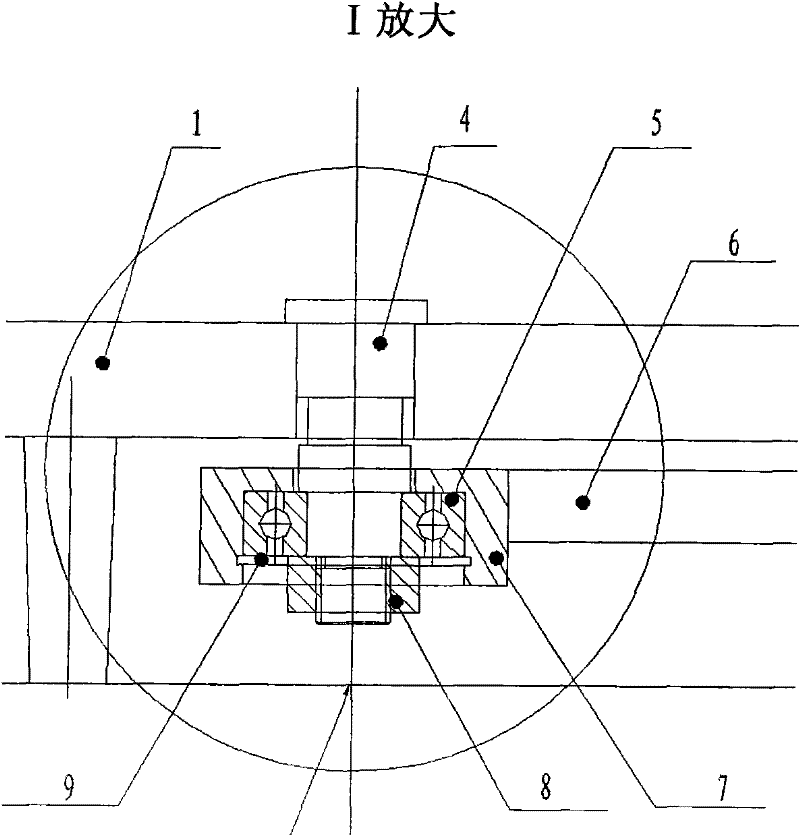

[0023] combine figure 2 , image 3 , Figure 4 As shown, the gear mechanism includes setting a central shaft 4 on the bottom plate 1 where the center of the sphere of the fixed pattern 3 is located, the central shaft 4 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com