Injection molding machine for interior shell

A technology of injection molding and injection machine, applied in the direction of coating, etc., can solve the problems of unsatisfactory design of manufacturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

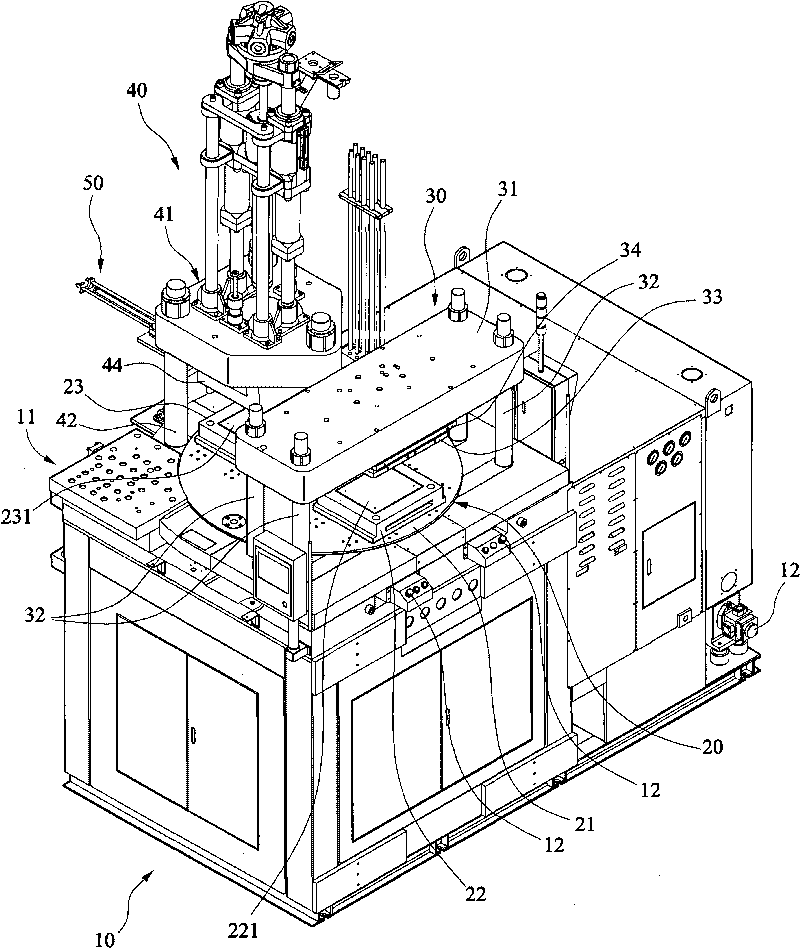

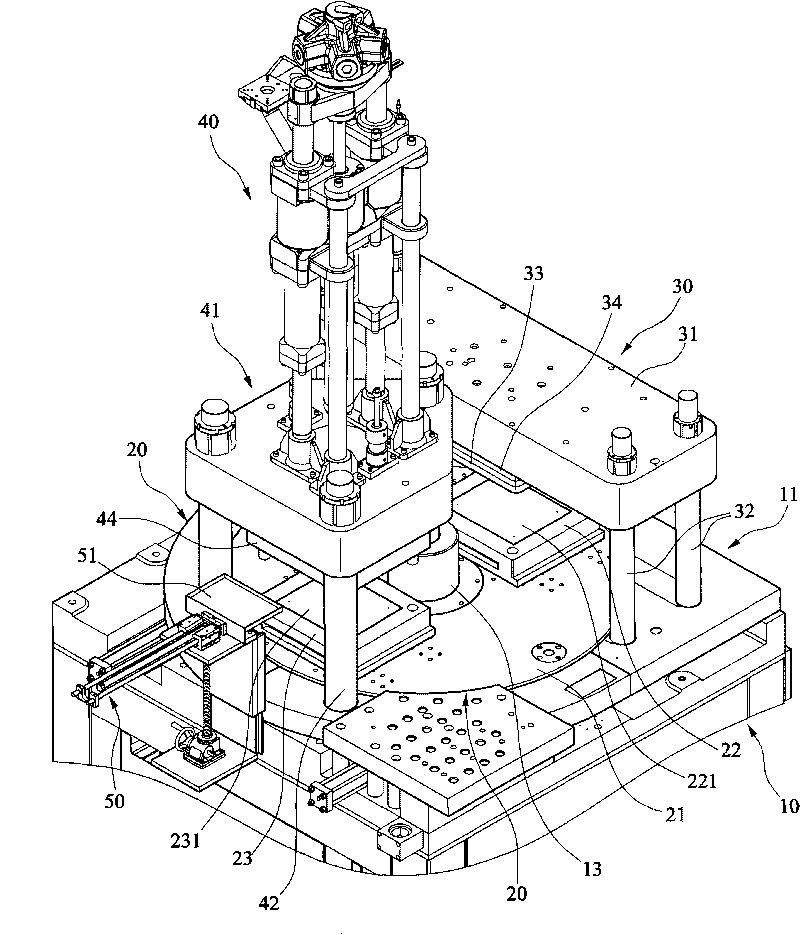

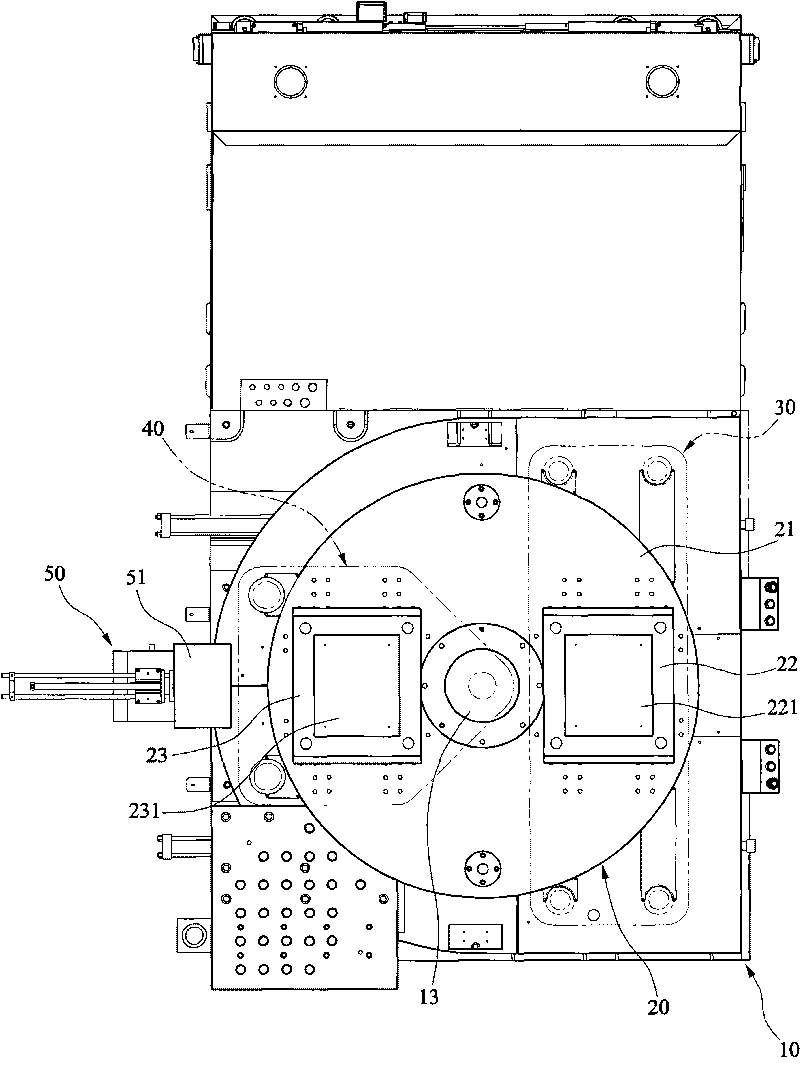

[0028] Please read Figure 1-4 The injection molding machine for interior film shell of the present invention includes a machine base 10, a conveying device 20, a forming device 30, an injection device 40, and a mechanical arm 50; Not shown in the figure), it is provided with an operation base 11 and various operation buttons 12; In this embodiment, it is a circular disc body (or other shaped disc body), and is driven by the power shaft 13 of the base 10 to rotate intermittently, please refer to Figure 5 , the conveying member 21 is respectively provided with lower molds 22, 23 on two corresponding sides, and the lower molds 22, 23 are generally the same mold, which has mold cavities 221, 231 designed in desired shapes.

[0029] Furthermore, the conveying lower molds 22, 23 of the conveying member 21 are implemented in other ways, for example, the conveying member 21 is formed by a conveyor belt, which also has the function of transferring the lower molds 22, 23.

[0030] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com