Vehicular rubbish compactor

A garbage compressor, vehicle-mounted technology, applied in garbage cans, garbage delivery, garbage collection, etc., can solve the problems of no transportation function, increase atmospheric carbon emissions, and small amount of garbage, and achieve simple structural design, enhanced overall strength, The effect of increasing the loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

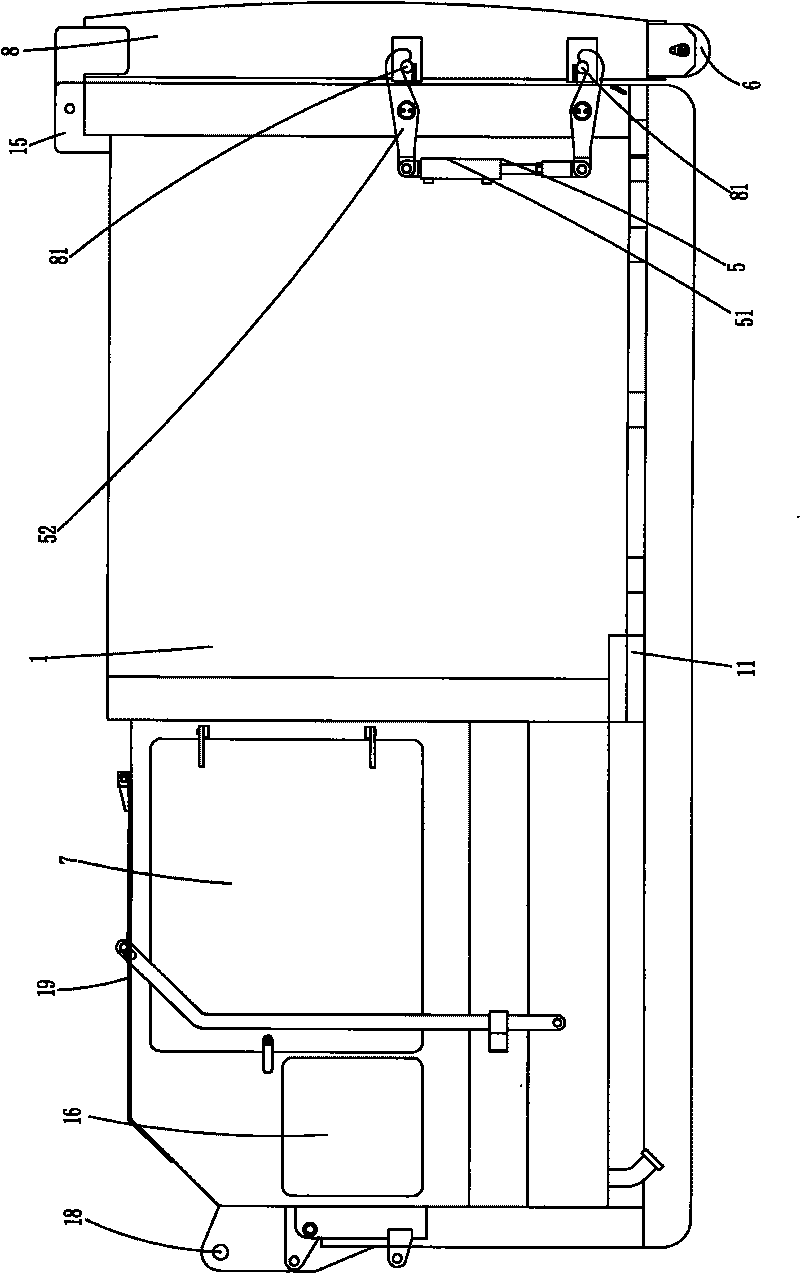

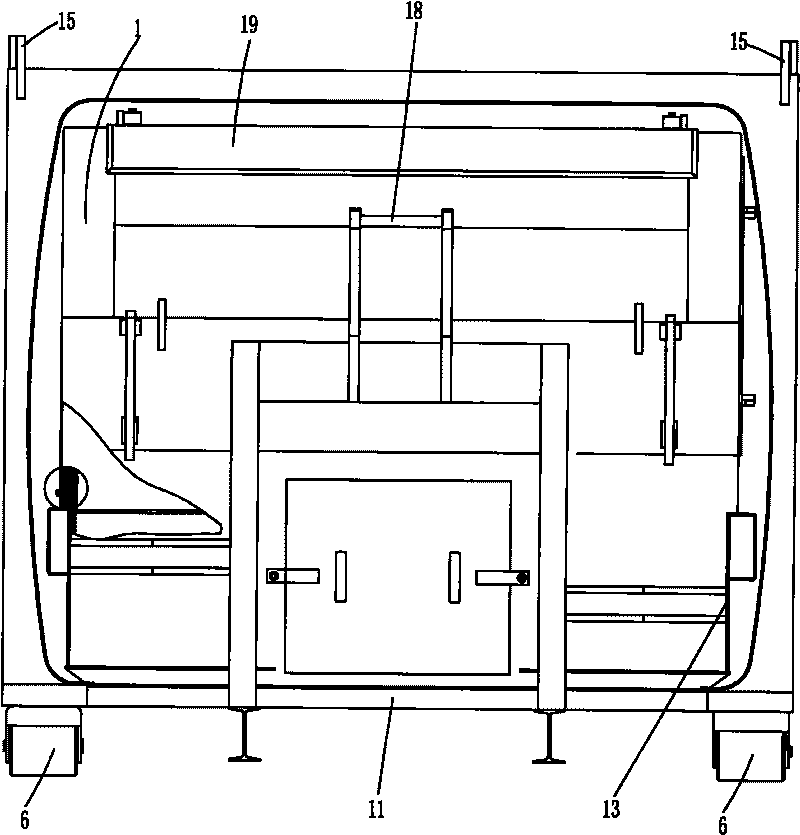

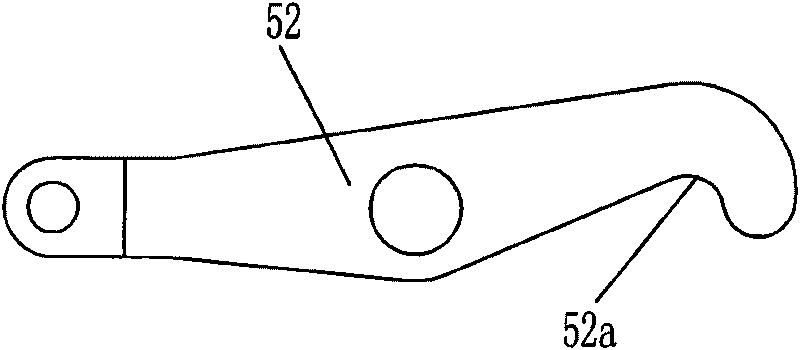

[0022] The structure of the embodiment of the present invention see Figure 1 to Figure 5 shown. Description of icon numbers: box body 1, compression bin 1a, feed bin 1b, storage bin 1c, bottom plate 11, storage inlet 12, long pull plate 13, window opening 14, hinge block 15, power source bin 16, discharge Mouth 17, pull hook 18, material cover 19, compression mechanism 2, push head 21, partition wall 3, front edge 3a, button garbage block 4, warped edge 41, beveled edge 42, locking mechanism 5, locking oil cylinder 51, Fastening plate 52, fastening groove 52a, roller assembly 6, window door 7, opening and closing door 8, fastening shaft 81.

[0023] Embodiments of the present invention, such as Figure 4 , Figure 5 As shown, the vehicle-mounted garbage compressor includes a box body 1, the rear end of the box body 1 is provided with a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com