System and method for optimizing control of track of rotary crane

A trajectory optimization and control system technology, applied in the directions of load hanging components, transportation and packaging, can solve problems such as inability to guarantee linear motion, difficulty in trajectory tracking or coordination, and space limitations for safe motion, and achieve convenient positioning control, expansion, etc. The effect of lifting capacity and improving movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

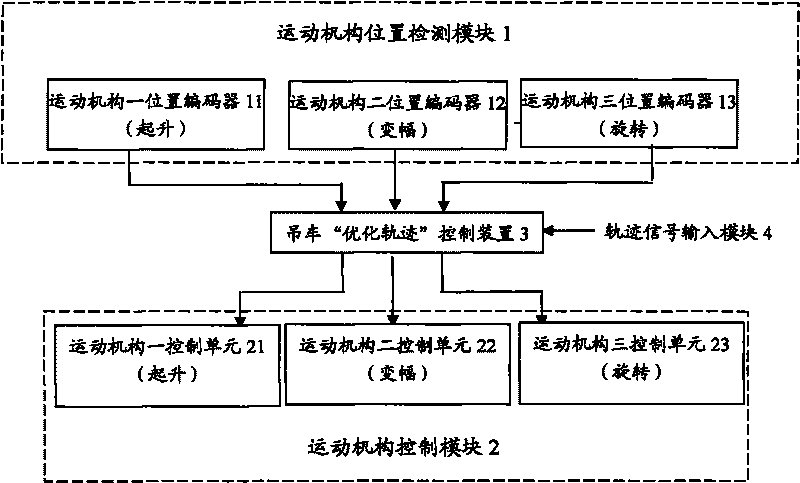

[0032] see figure 1 As shown in the trajectory optimization control system of the rotary crane, the rotary crane includes a spreader movement mechanism, and the spreader movement mechanism includes several movement mechanisms, wherein the control system includes a crane optimal trajectory control device 3. The position detection module 1 of the kinematic mechanism of the spreader and the position control module 2 of the kinematic mechanism of the spreader, the crane optimized trajectory control device 3 is connected with the position detection module 1 of the kinematic mechanism of the spreader and the position control module of the kinematic mechanism of the spreader respectively 2, and the position detection module 1 of the moving mechanism of the spreader and the position control module 2 of the moving mechanism of the spreader are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com