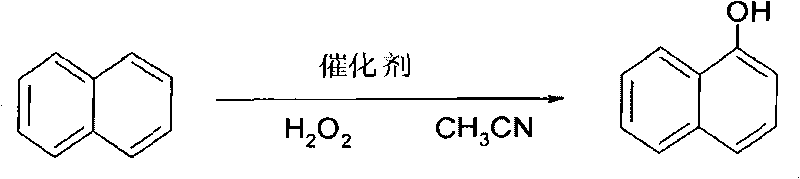

Method for preparing 1-naphthol by using pigment green B catalysis

A technology for catalytic preparation and pigment green, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of large process pollution, poor safety, complex process, etc., and achieve simple operation and low pollution , Ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In a 100 mL four-necked flask equipped with a thermometer and a stirring device, 0.26 g of naphthalene, 18 g of acetonitrile, and 0.01 g of Pigment Green B catalyst were added. Heat up to 75°C, add dropwise 30% H over 0.5h 2 o 2 2g, keep warm for 5h. Filter, take the filtrate and measure the content of naphthalene and 1-naphthol with gas chromatography external standard method. The conversion rate of naphthalene was 30.2%, and the yield of 1-naphthol was 18.3%.

Embodiment 2

[0017] In a 100 mL four-necked flask equipped with a thermometer and a stirring device, 0.256 g of naphthalene, 30 g of acetonitrile, and 0.03 g of Pigment Green B catalyst were added. Heating to 45°C, adding 30% H 2 o 2 5g, with 2h, heat preservation reaction 18h. After cooling, the catalyst was filtered off, and the filtrate was measured by gas chromatography external standard method. The conversion rate of naphthalene was 40.3%, and the yield of 1-naphthol was 15.3%.

Embodiment 3

[0019] In a 100 mL four-necked flask equipped with a thermometer and a stirring device, add 0.256 g of naphthalene, 13 g of acetonitrile, and 0.005 g of Pigment Green B catalyst. Heat up to 55°C, add 30% H 2 o 2 1.5g, use time 0.5h, heat preservation reaction 15h. After cooling, the catalyst was filtered off, and the filtrate was measured by gas chromatography external standard method. The conversion rate of naphthalene was 38.7%, and the yield of 1-naphthol was 17.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com