Method for heat treatment of P92 steel

A heat treatment method and resistance heater technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as unsatisfactory, inability to effectively guarantee weld impact performance, and increased embrittlement tendency of P92 steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Use the P92 main steam pipe of Φ538mm*91mm to weld according to the P92 steel welding process, and install a monitoring hot couple on the inner wall of the pipe before welding.

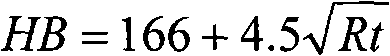

[0044] 2. Calculate the width of the heating zone HB=976mm, the width of the heat preservation zone GCB=1710mm, and customize the specifications of the heater and heat preservation cotton according to the calculated data.

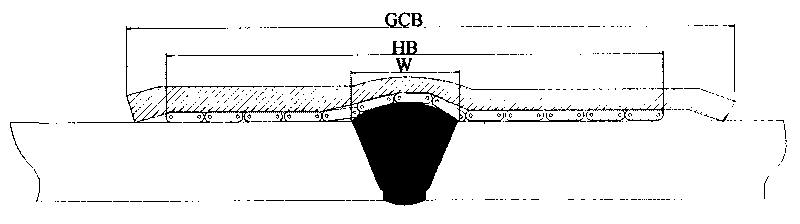

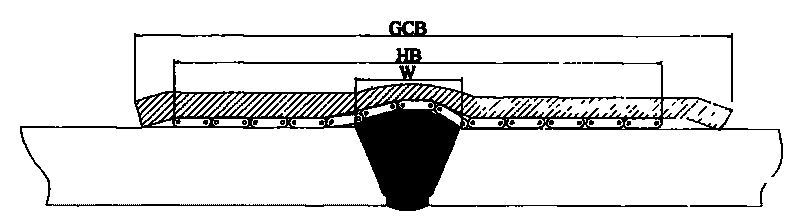

[0045] 3. When the P92 pipe is welded and slowly cooled to 140°C, immediately press figure 1 The heater is installed as shown, the temperature control thermocouple is arranged in the center of the weld, and the temperature is controlled in three zones. When the temperature drops to 95°C, power on to keep the temperature at this temperature for 2 hours.

[0046] 4. Heating at 150°C / h to 300°C.

[0047] 5. After the temperature reaches 300°C, raise the temperature to 768°C at 80°C / h and keep it warm for 8 hours. At this time, the temperature difference between the monitor...

Embodiment 2

[0054] 1. Use the P92 main steam pipe of Φ433mm*72mm to weld according to the P92 steel welding process, and install a monitoring hot couple on the inner wall of the pipe before welding.

[0055] 2. Calculate the width of the heating zone HB=815mm, the width of the heat preservation zone 6CB=1370mm, and customize the specifications of the heater and heat preservation cotton according to the calculated data.

[0056] 3. When the P92 pipe is welded and slowly cooled to 140°C, immediately press figure 1 The heater is installed as shown, and the temperature control thermocouple is arranged in the center of the weld, and the temperature is controlled in two areas. When the temperature drops to 90 ° C, power on to keep the temperature at this temperature for 2 hours.

[0057] 4. Heating at 150°C / h to 300°C.

[0058] 5. After the temperature reaches 300°C, raise the temperature to 768°C at 80°C / h and keep it warm for 6 hours. At this time, the temperature difference between the moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com