Method and sewing machine device for shortening residual line tail of sewing workpiece

A work piece and thread tail technology, which is applied to sewing machine components, thread cutting mechanisms in sewing machines, sewing equipment, etc., can solve the problems of reducing automatic thread trimming, increasing labor time and cost, and shortening the residual thread tail. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

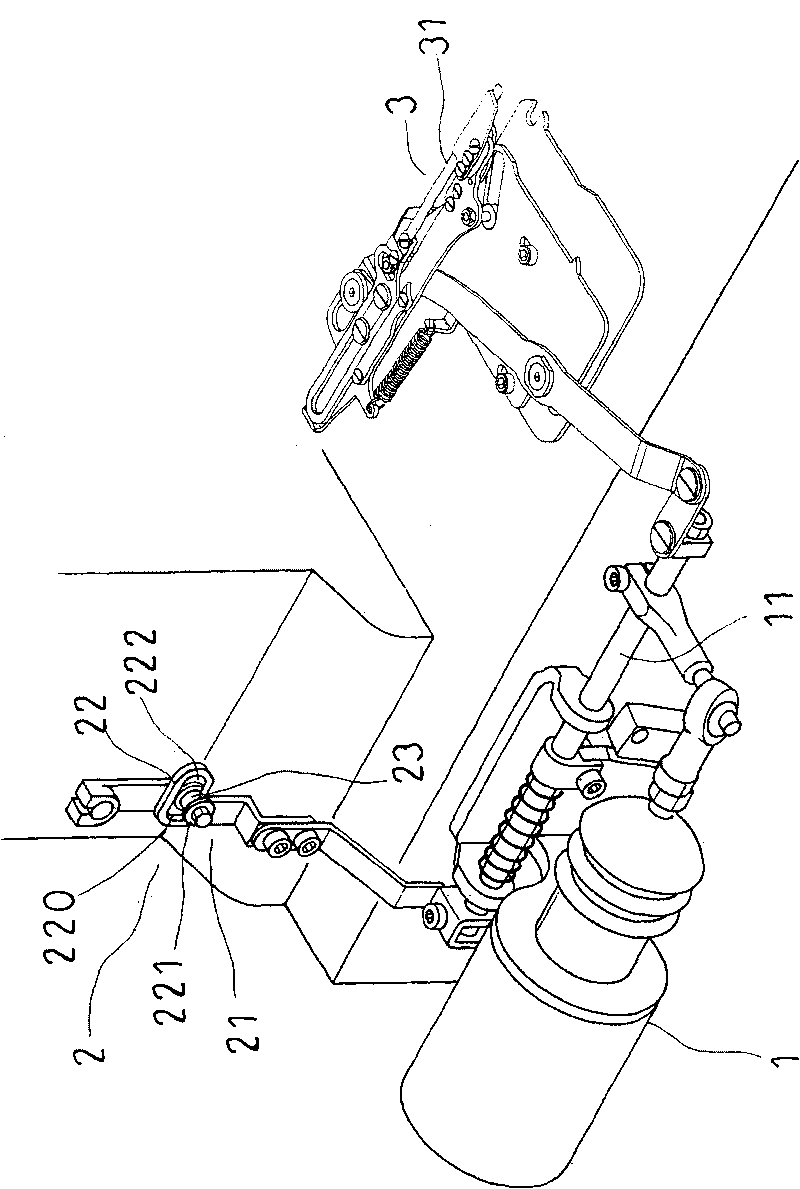

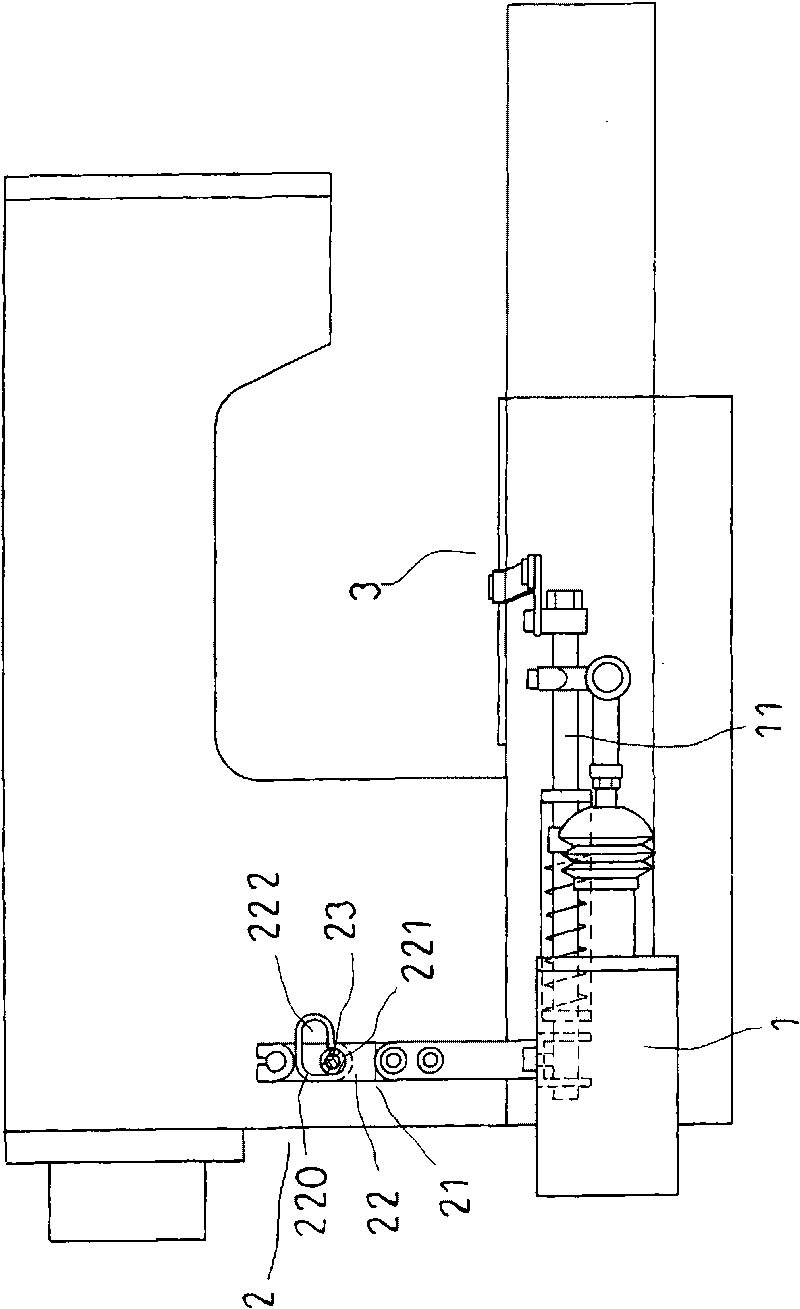

[0028] First, see Figure 1 to Figure 7 As shown, it is a sewing machine device embodiment 1 of the present invention that shortens the residual thread tail of the sewing work piece and the flow block diagram, three-dimensional decomposition, partial decomposition and combination action schematic diagram of the method. The shortening of the sewing work piece residual provided by the invention The thread tail method is to use the actuating rod 11 of the electromagnetic driver 1 to drive the thread loosening device 2 and the thread cutting device 3 to carry out the thread loosening and thread cutting strokes, so as to achieve the purpose of shortening the residual thread tail of the sewing work piece 5, which includes the steps :

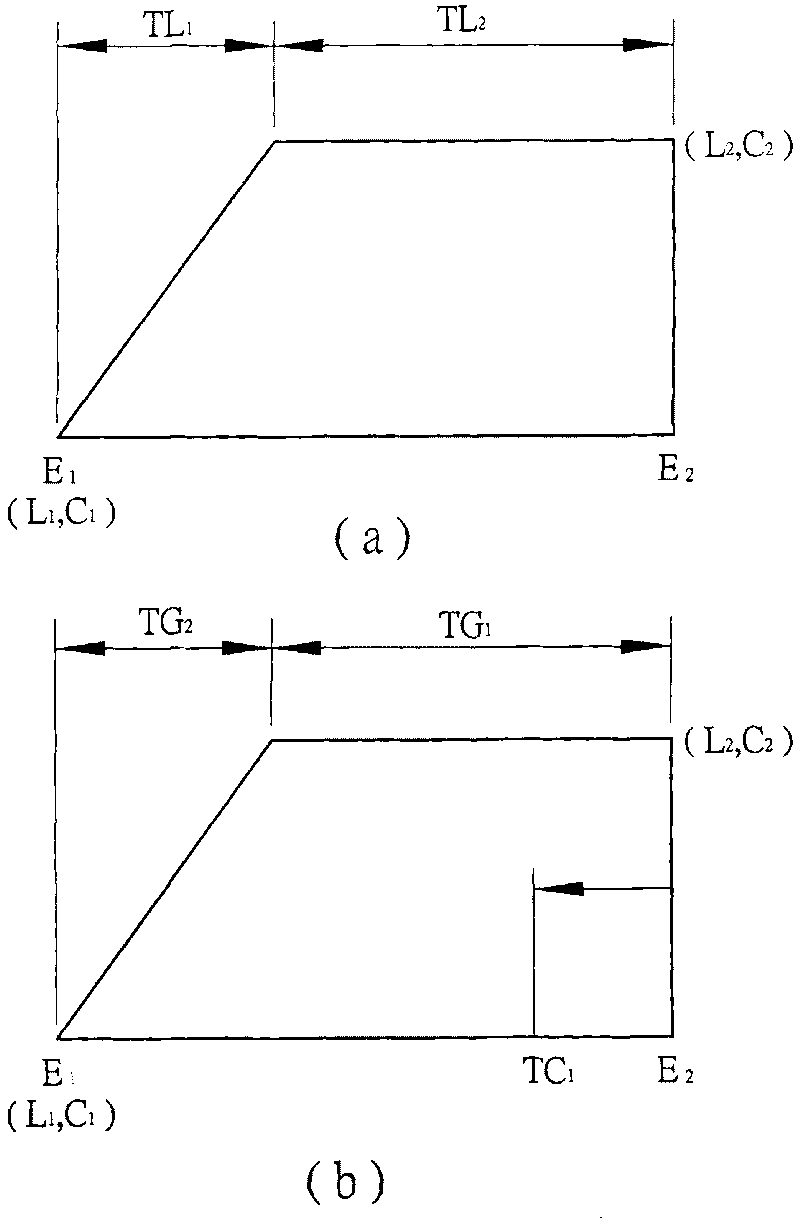

[0029] a), starting step: at the starting point E of the electromagnetic driver 1 To the end point E of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com