Digital pulse variable axial plunger pump

An axial piston pump, digital pulse technology, applied in the direction of pump, multi-cylinder pump, liquid variable capacity machinery, etc., can solve the problems affecting the working efficiency of the piston pump, low sensitivity, poor stability, etc., to achieve no lag, Good stability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

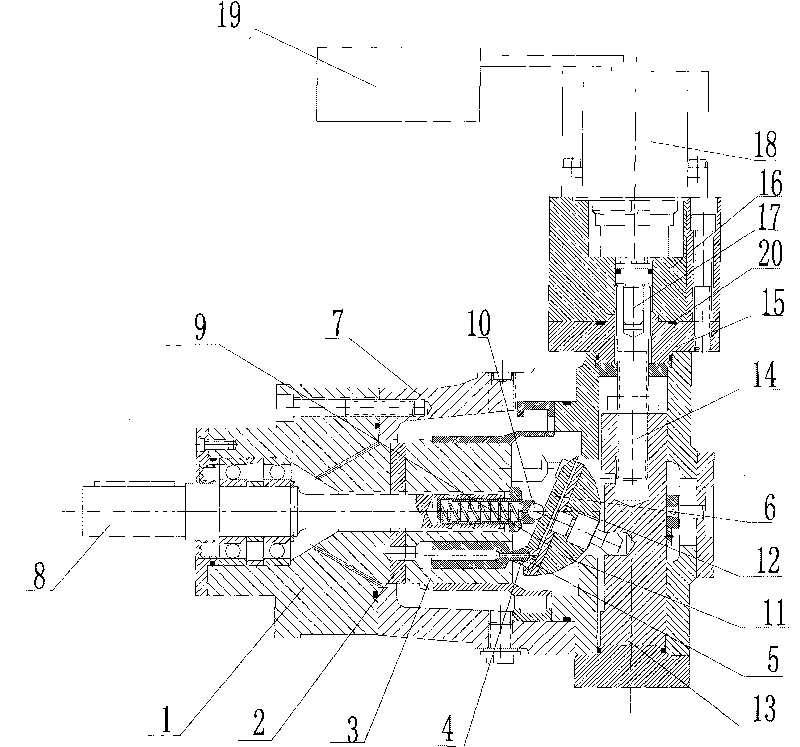

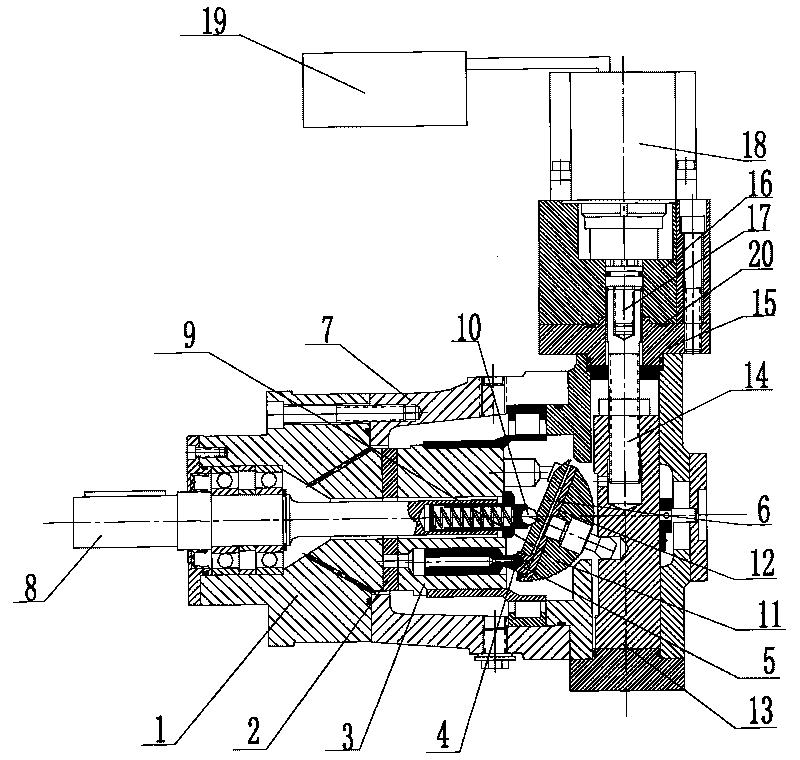

[0012] Such as figure 1 , the digital pulse variable axial plunger pump of the present invention includes a pump body 1, an oil distribution plate 2, a cylinder body 3, a plunger 4 arranged in the cylinder body 3, a sliding shoe 5 installed at the end of the plunger 4, a return stroke Disk 6, pump casing 7, transmission shaft 8 and variable control device 9, cylinder body 3 is installed on the end of transmission shaft 8, and the end of transmission shaft 8 is fixed on the center line of return disk 6 by steel ball 10, variable control The device 9 includes a variable head 11, a thrust plate 12, a variable shaft 13 and an adjusting screw 14. The axial piston pump is also provided with a transition body 16. One end of the transition body 16 is fixedly connected with the flange 15, and the other end is connected with a straight line Stepper motor 18, the main shaft of the linear stepper motor 18 is fixedly connected with the taper pin 17, the other end of the taper pin 17 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com