Method for adjusting and uniform controlling temperature in each return stroke of multi-return stroke roller drier

A drum dryer, uniform control technology, applied in the direction of dryer, drying gas arrangement, drying, etc., can solve the problem that the heating temperature cannot be controlled in sections, and achieve the effect of temperature adjustment and stable and uniform control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

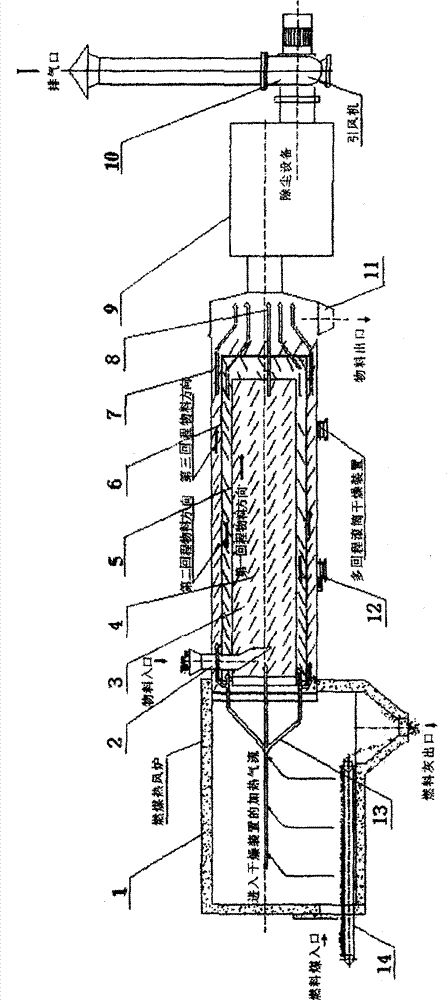

[0023] An embodiment of the present invention—a three-pass drum dryer for coal dehydration and upgrading will be described below in conjunction with the accompanying drawings.

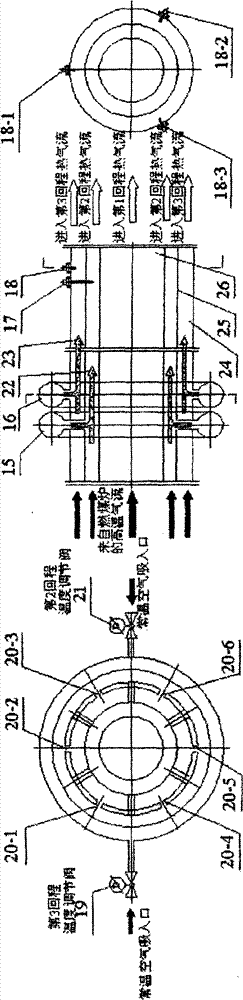

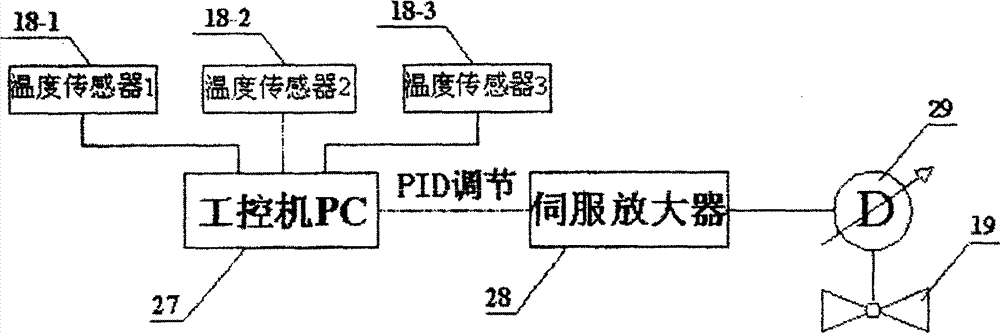

[0024] Figure 4 It shows the structure and principle of the three-pass drum dryer whose temperature can be adjusted separately and uniformly controlled in the present invention. Present embodiment is in traditional drum dryer structure ( figure 1The improvement made on the basis of shown) is mainly composed of combustion furnace, three-pass drum drying device, drum driving device, fuel delivery and combustion device, dust removal equipment, induced draft fan and other parts. The difference is that, at the inlet of the heating air flow from the combustion furnace of the traditional three-pass drum dryer to the right side of the drum drying device, the pressure equalizing air distribution ring 15 from the middle mixing air channel and the pressure equalizing air distribution ring from the external mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com