Plate-type heat exchanger

A plate heat exchanger, a form of technology, applied in the field of brazed aluminum plate heat exchangers, to achieve the effect of simple structural measures and increase the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

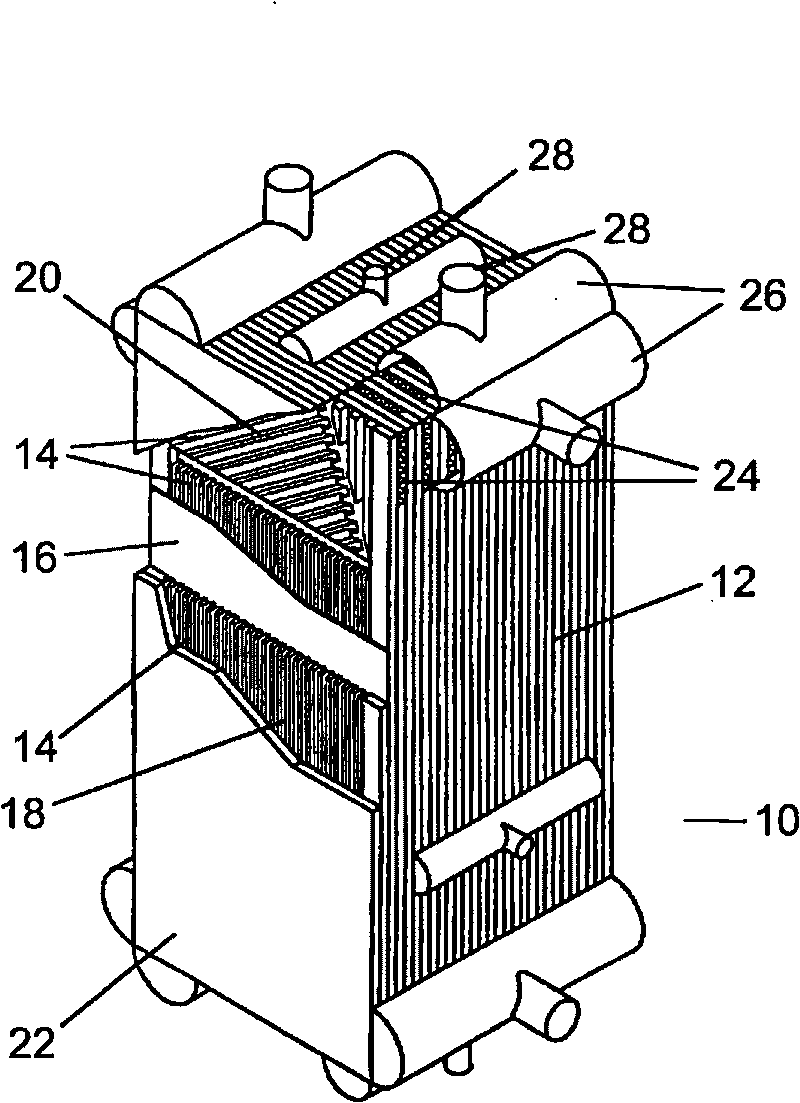

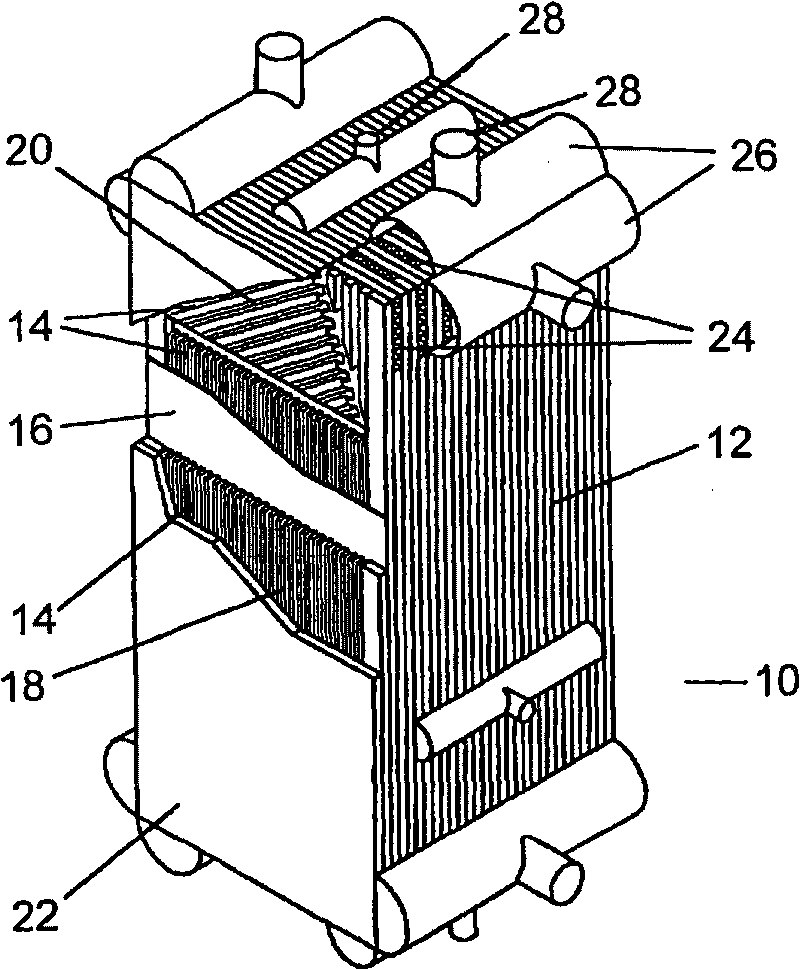

[0024] figure 1 is a perspective view of a plate heat exchanger 10 according to the invention, in particular a brazed aluminum plate heat exchanger. The plate heat exchanger 10 has a central heat exchange section (also referred to as a heat exchange block 12), for example, the heat exchange section has the following dimensions: a length of about 6 meters (in figure 1 The top-bottom direction range of ) and in each case, the width and height are about 1.2 meters.

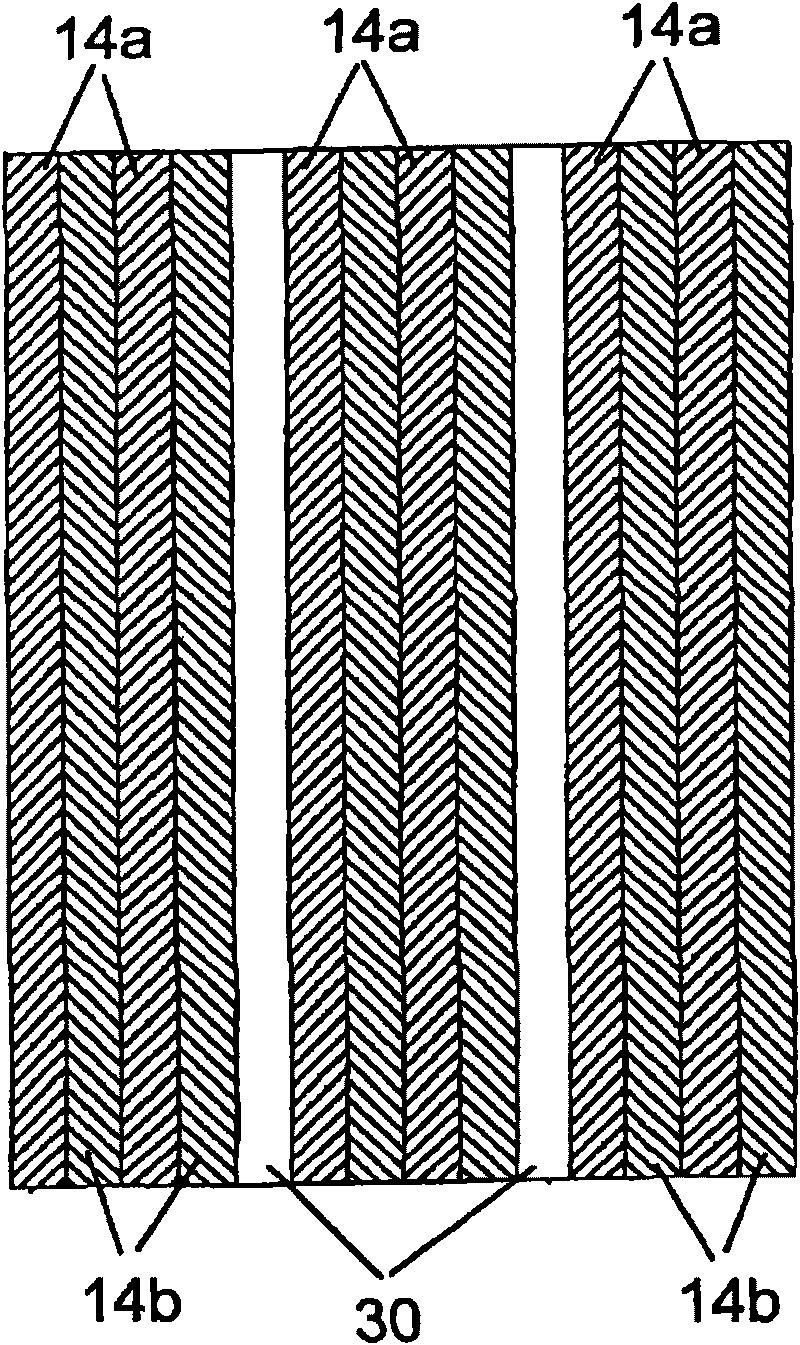

[0025] Inside the heat exchanging portion 12 are provided a plurality of heat exchanging passages 14 (heating passages, cooling passages). These heat exchange channels 14 are formed by alternating layers of separating plates 16 and heat exchange profiles 18 (eg ribbed or corrugated plates, fins) or distributor profiles 20 . The plate heat exchanger 10 of the exemplary embodiment takes the form of a two-flow heat exchanger, that is, it comprises first channels 14a and second channels 14b alternately parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com