Surface artificial electromagnetic material applied to directional radiation modulation

An artificial electromagnetic material and directional radiation technology, applied in the direction of circuits, magnetic objects, electrical components, etc., can solve the problems of physical phenomena that do not support the surface plasmon mode, and achieve the effect of high refractive index, simple structure processing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

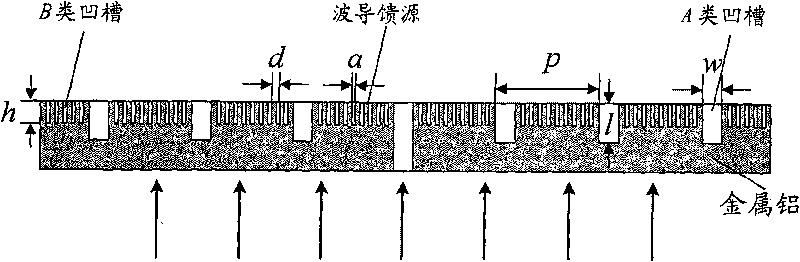

[0033] Embodiment 1, the manufacturing process of a surface artificial electromagnetic material applied to directional radiation modulation is as follows:

[0034] (1) The base material of the metal is selected as aluminum, and the thickness of the aluminum plate is 15mm;

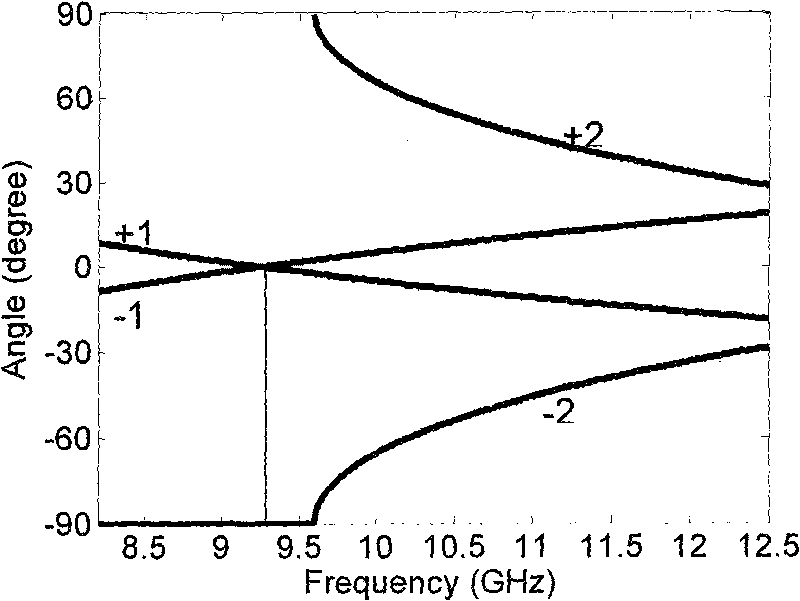

[0035] (2) The waveguide feed source is a flat rectangular waveguide BB100, and the width of the waveguide on the E plane is only 5.0mm. The frequency range of the radiation source is between 8.2GHz and 12.5GHz, and the corresponding wavelength range is 24mm to 36.6mm, and the wave vector k 0 0.17mm range -1 ~0.26mm -1 , in the microwave band;

[0036] (3) Select the period of type A groove as p30mm, which is equivalent to the radiation wavelength of the radiation source, the width w of type a groove is 5.0mm, and the depth l is 4.5mm;

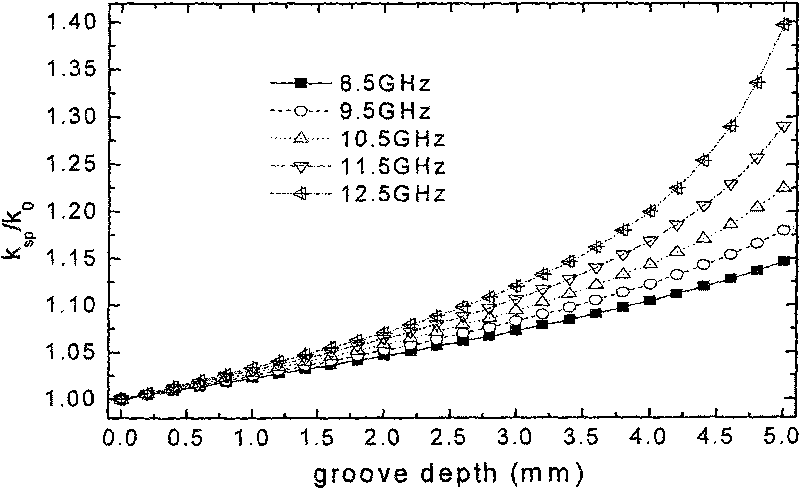

[0037] (4) The period d of the B-type groove is 2.38mm, the width a of the B-type groove is 1.2mm, and the adjustment law of the depth h to the wave vector of the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com