Through hole etching method

A technology of through-hole etching and etching stop layer, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems such as the inability to reduce the feature size of the through-hole and increase the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

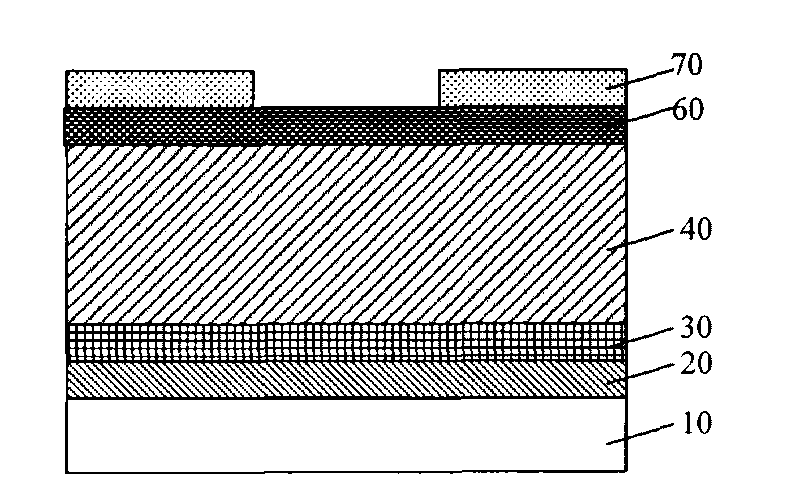

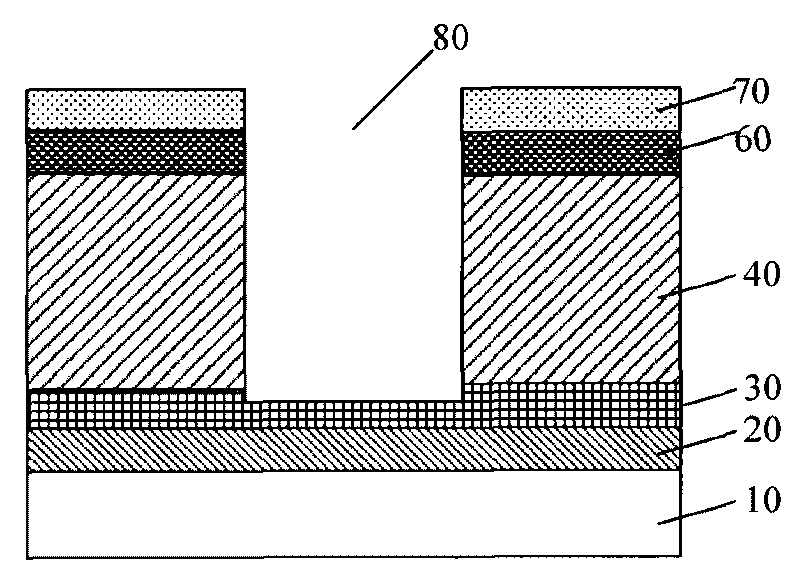

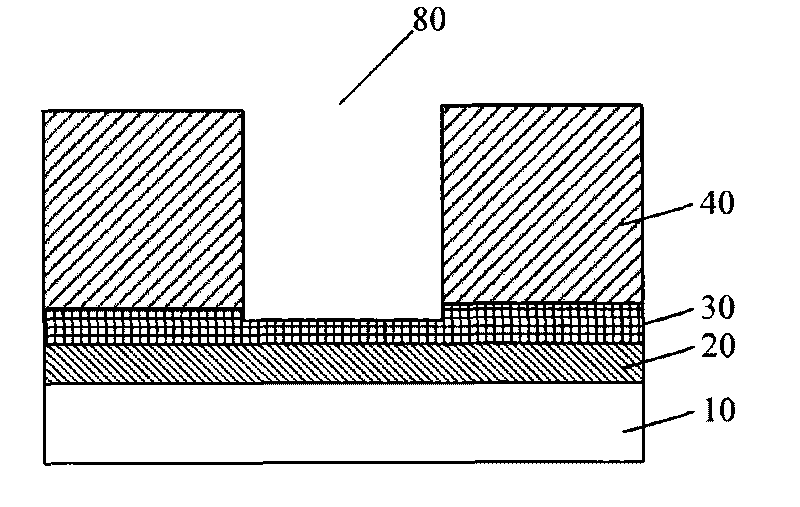

[0034] As described in the background art, in order to reduce the feature size of the via hole formed on the device, the pattern formed by the photoresist layer 70 can be precisely formed to ensure that the reserved via hole size is a set smaller feature size. In order to accurately form the pattern of the photoresist layer 70 , it is necessary to improve the exposure and development techniques of the prior art, which is not only difficult to achieve but also greatly increases the cost.

[0035] Therefore, in order not to change the existing exposure and development methods, the through hole obtained by etching can also reach the set relatively small through hole feature size, when the present invention uses HBr to etch the bottom anti-reflection coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com