Decontamination box of long workpieces

A technology of long workpieces and workpiece racks, which is applied in the field of long workpiece decontamination boxes, can solve the problems of poor decontamination effect and narrow application range, and achieve the effects of improving decontamination ability and speed, strong adaptability, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

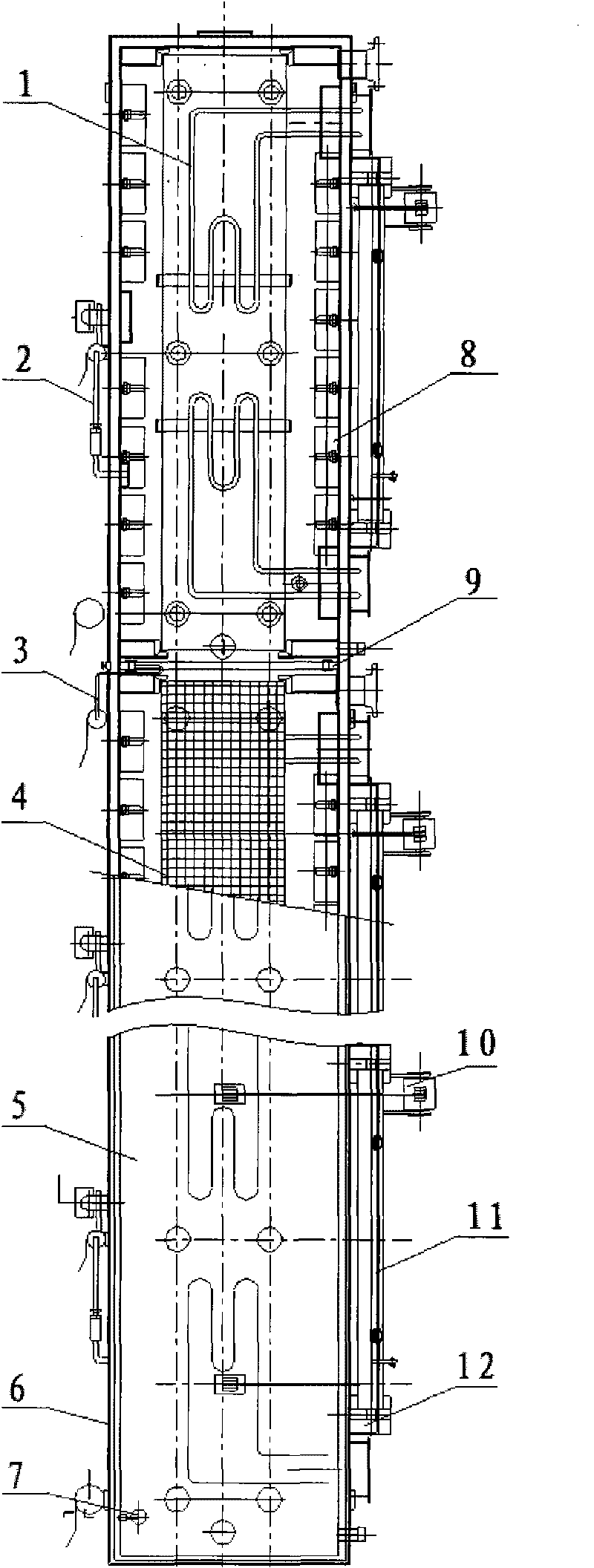

[0020] Such as figure 1 As shown, the box body 6 of the long workpiece decontamination box of the present invention is divided into three independent working sections by two detachable partitions 9, and a pair of heating tubes 1 in the shape of an s are arranged at the bottom of each working section. , a workpiece frame 4 is arranged above the heating tube, there is a certain distance between the workpiece frame 4 and the heating tube 1, and six and seven ultrasonic vibration boxes 8 are respectively set on both sides of the box body 6, and each working area is There is an independent box cover 5, and a ventilation hole 7 is opened on the box cover 5, and a ventilation interlocking device 12 is arranged on the outside of the box body 6, which is connected with the switch cover device 10 through a connecting rod 11, and the box in each working area The outside of the body 6 is also provided with a liquid inlet pipe 2 and an air inlet valve 3 .

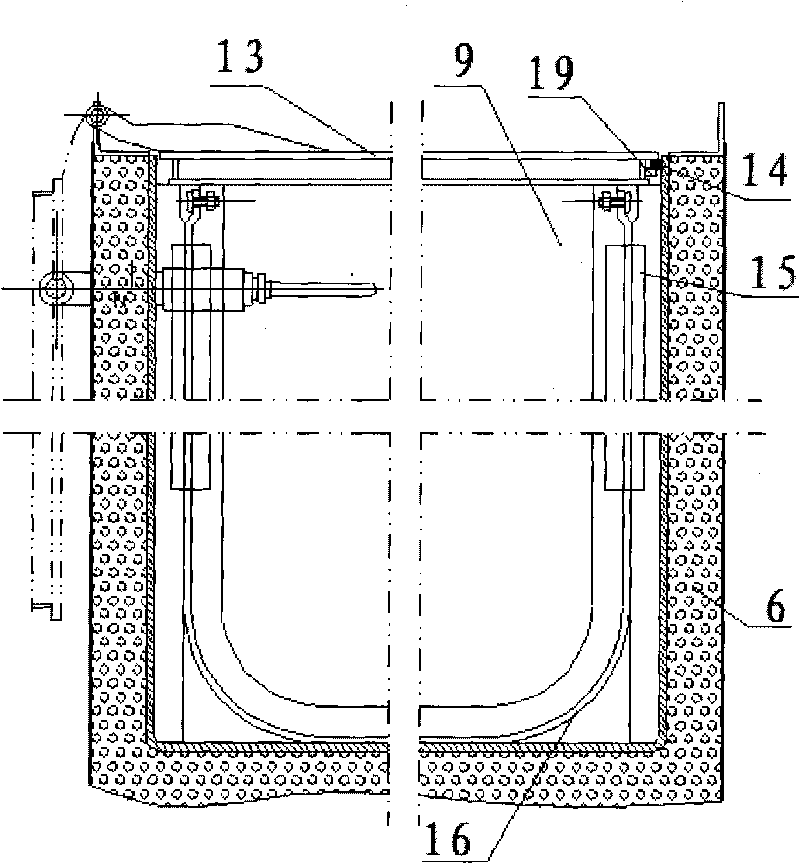

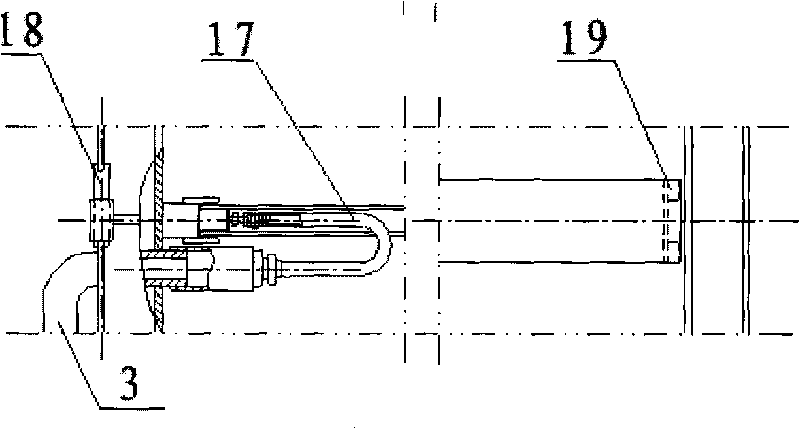

[0021] Such as figure 2 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com