Crowner head of overlay on bottling line of beverage

A production line and beverage technology, applied in the field of mechanical equipment, can solve problems such as inaccurate positioning, complicated magnet installation, and different magnetic strength of magnets, and achieve the effects of balanced spring force, stable and reliable work, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

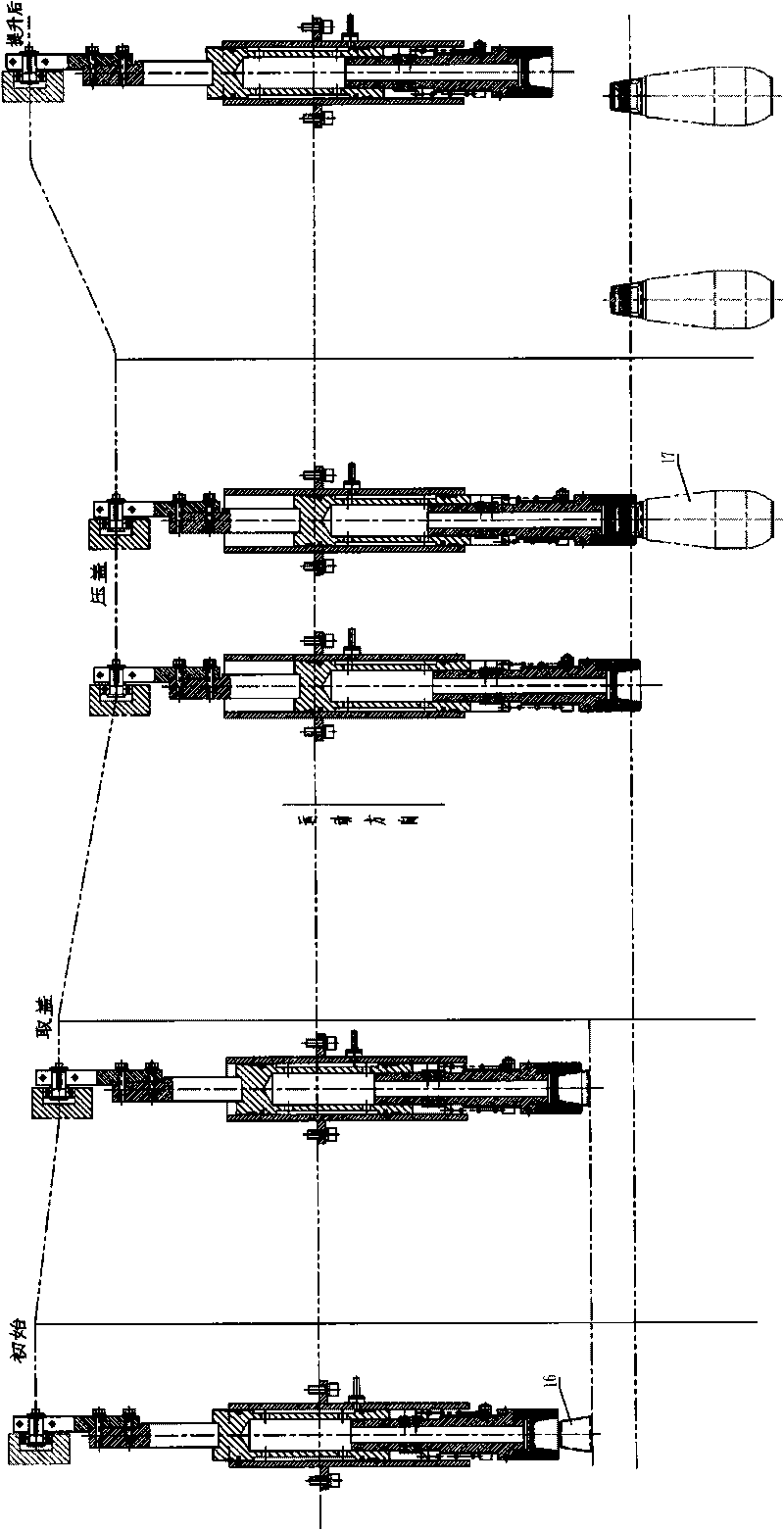

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

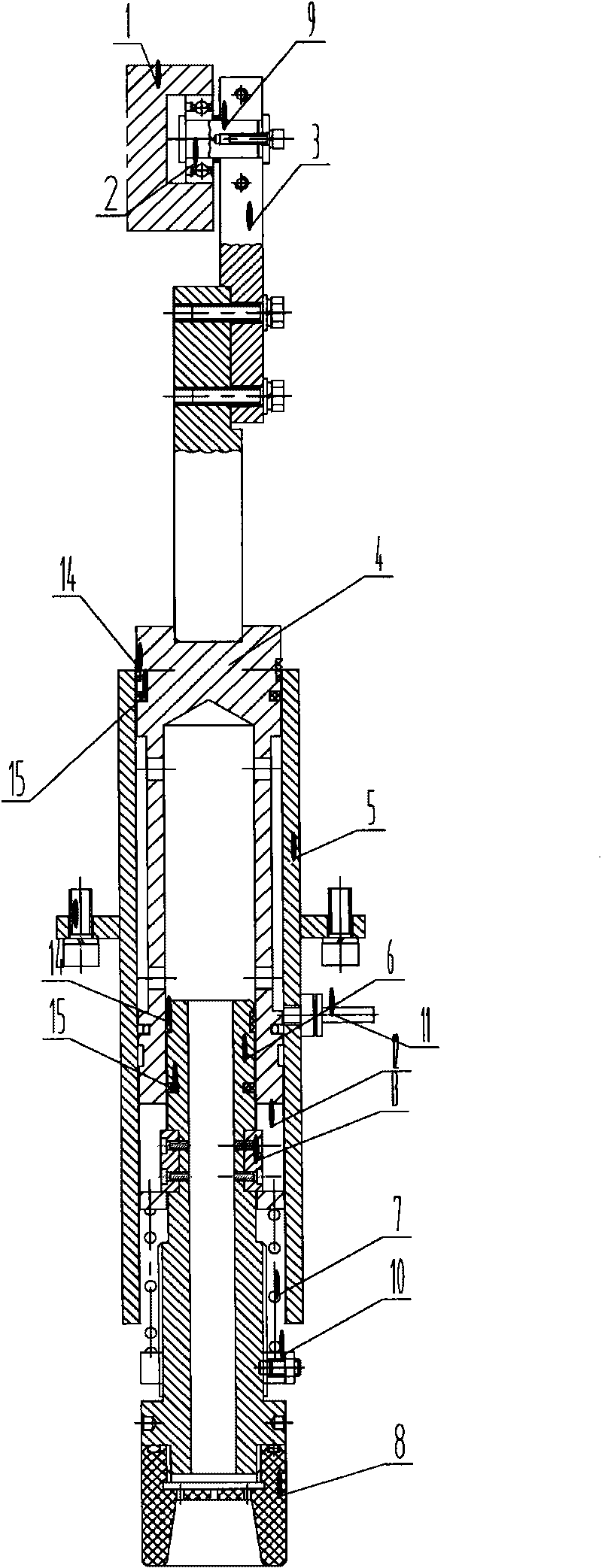

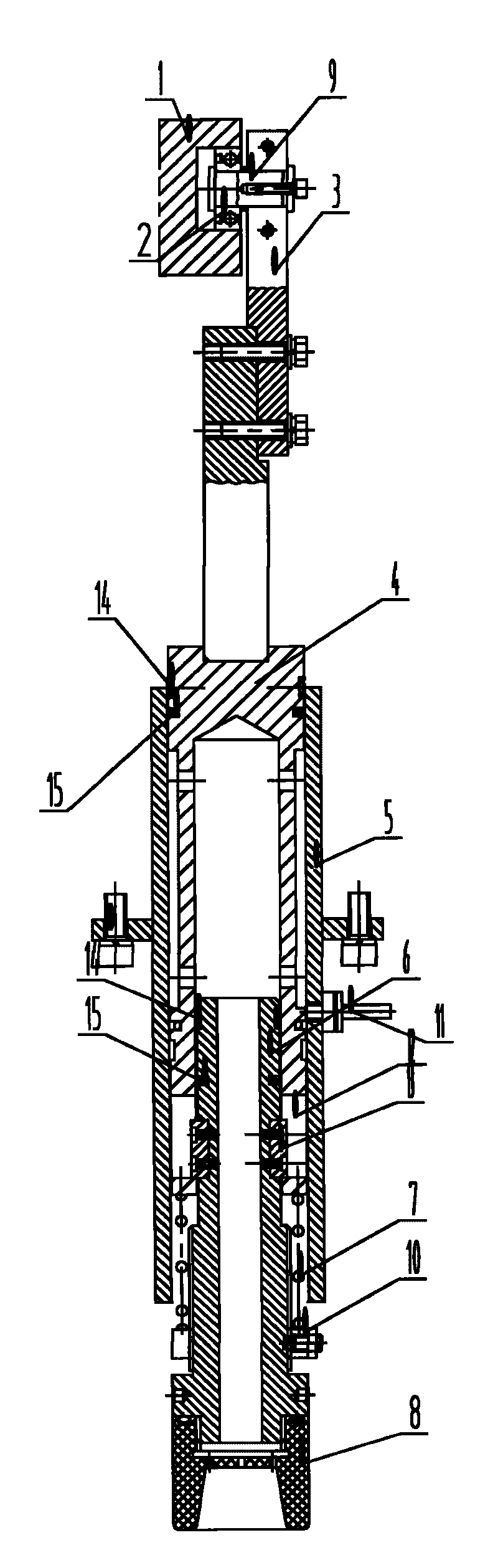

[0013] Such as figure 1 As shown, a decorative capping head on a beverage filling production line mainly includes a roller 2, a connecting frame 3, a sliding shaft 4, a sleeve 5, a mandrel 6, a spring 7 and a container cap 8, wherein:

[0014] The roller 2 is supported on the side of the connecting frame 3 through the small shaft 9, and the roller 2 runs along the guide groove 1. The lower end of the connecting frame 3 is connected to the sliding shaft 4 through the connecting rod. The sleeve 5 is sleeved on the outer edge of the sliding shaft 4. The sliding shaft 4 can slide in the sleeve 5 inside the sleeve 5. When the sliding shaft 4 and the sleeve 5 are in contact The surface is provided with a friction ring 14 and an Otto ring 15 .

[0015] The mandrel 6 upper end stretches in the inner hole of slide shaft 4 and can slide in the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com