Method for treating biological sewage

A sewage biological treatment and sewage treatment technology, which is applied in the field of water reduction and shortening of water treatment time, can solve the problems of high construction cost and treatment cost, inconvenient management, and complicated operation, so as to reduce operating costs, save time and costs. , the effect of large processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

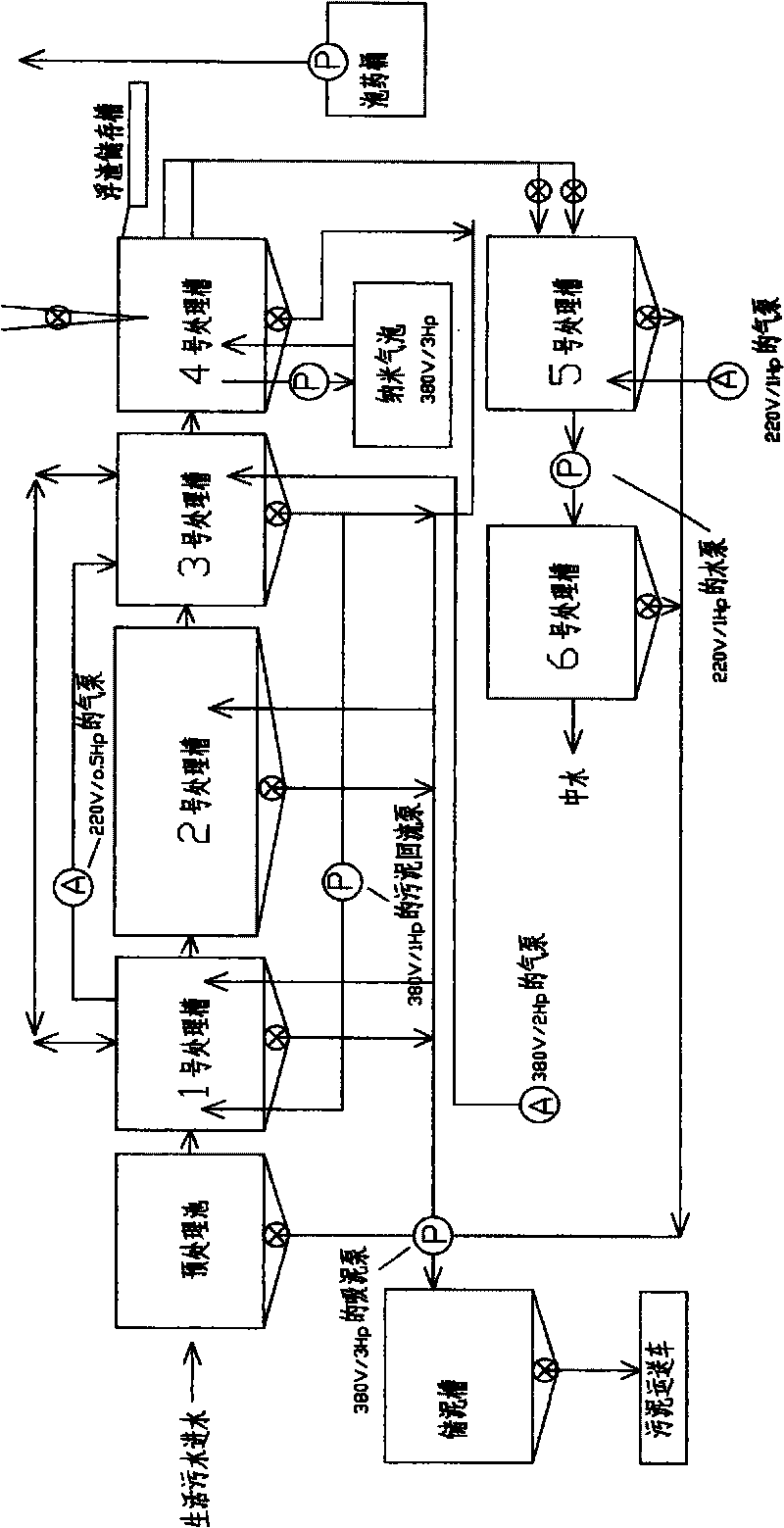

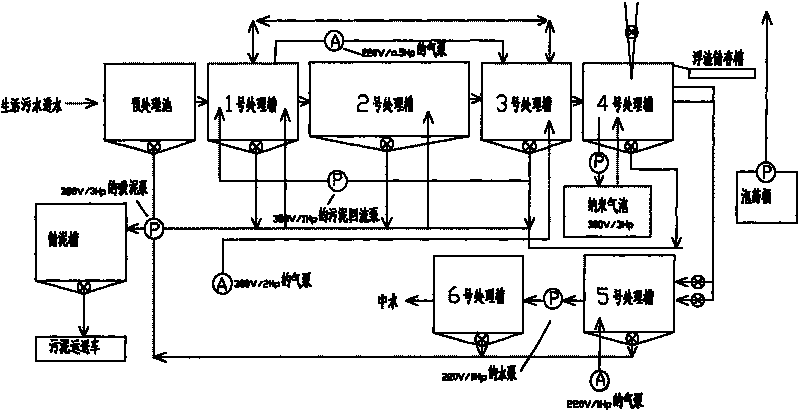

[0011] Such as figure 1 As shown, based on the physical environment of anaerobic, aerobic and anoxic biological filters, a more complete set of biological treatment sludge is produced after the combination of different operating methods and new treatment equipment. The method is a new method to reduce the amount of sludge in the sewage treatment process and improve the treatment efficiency. First, the organic matter contained in the sludge is digested and decomposed through the anaerobic process in the No. 1 treatment tank, and the non-continuous air bubbles are used to stir After the sludge is mixed, the concentration of organic matter, microbial distribution, temperature, and PH value in the pool are all uniform, which improves the sludge digestion speed and shortens the digestion time; in addition, the sludge deposited and discharged from the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com