Submerged aeration water culturing machine

A water cultivator and aeration technology, applied in water aeration, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of lack of irradiation, poor activity, rapid bacterial reproduction, etc., to optimize breeding The effect of environment, energy saving and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

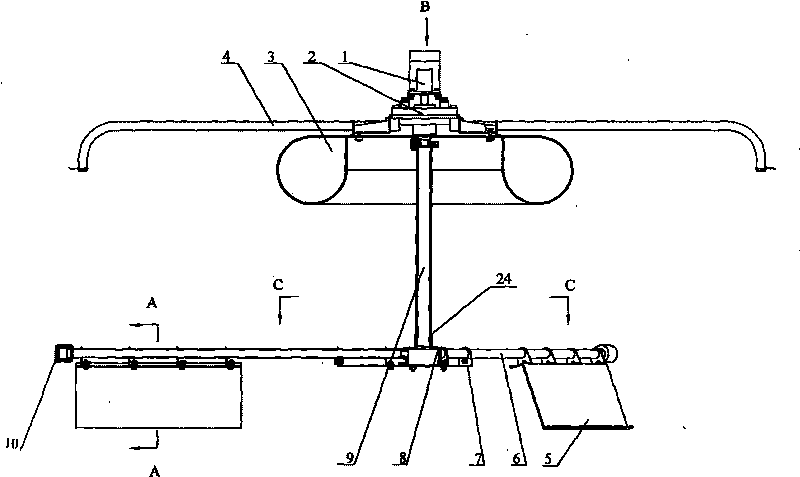

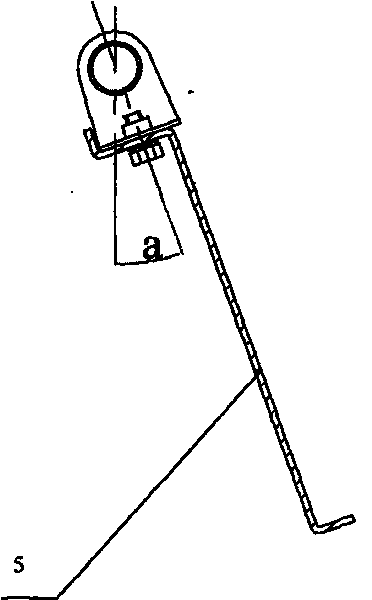

[0029] Such as figure 1 As shown, the submersible aeration water cultivator according to the present invention includes a float 3, a positioning rod 4, a water cultivation mechanism and an aeration mechanism.

[0030] Described plowing and watering mechanism comprises drive motor 1 and reduction gear 2 connected with it, rotating shaft 24, blade 5, and one end of described rotating shaft 24 is connected with reduction gear 2 driven by driving motor 1, and the other end is centered on rotating shaft 24 There are a plurality of horizontal vane tubes 6 radially distributed, and blades 5 are installed under the horizontal vane tubes 6; in actual use, the horizontal vane tubes 6 sink into the water and are driven by the reduction device 2 The blades 5 rotate.

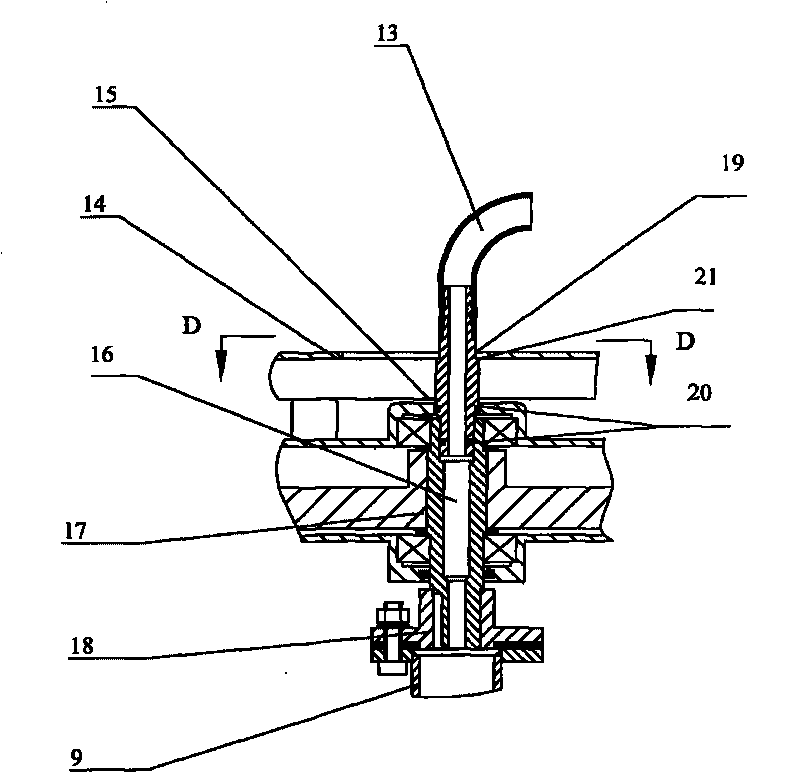

[0031] Such as image 3 , Figure 5 and Figure 6 As shown, there are a gear 17 and an output shaft 16 in the reduction gear 2, and a flange 18 is installed at the lower end of the output shaft 16, and a round hole is a...

Embodiment 2

[0040]The difference between the second embodiment and the first embodiment lies in the structure of the junction of the intake pipe 19 and the deceleration device, such as Figure 4 shown. The upper end of the output shaft 16 of the deceleration device passes through the opening on the deceleration device housing 15, and several annular grooves are opened on the output shaft 16, and the sealing ring 20 is set on the annular groove, and the sealing ring 20 and the hole on the deceleration device housing 15 Fit seal.

Embodiment 3

[0042] The difference between Embodiment 3 and Embodiment 1 is that the latter installs aeration elements at the end of the horizontal tube of the blade, while the former only directly sets exhaust holes on the horizontal tube of the blade, such as Figure 8 shown. The aeration mechanism includes an air distribution device and an air pump 12 connected thereto. The air distribution device includes an air guide pipe 13, an air intake pipe 19, a standpipe 9, a standpipe lower joint 8 and a blade horizontal tube 6. The blade horizontal tube 6 There are some exhaust holes 25 on the top, and the gas is discharged from the air pump 12 through the air guide pipe 13, the intake pipe 19, the standpipe 9, the lower pipe 8 of the standpipe, and is discharged through the exhaust holes 25 on the blade horizontal tube 6. One end of the blade transverse tube 6 is connected and communicated with the lower pipe 8 of the standpipe, and the other end is closed. The standpipe and the standpipe do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com