Low-toxicity or nontoxic multi-functional drilling fluid finishing agent

A drilling fluid treatment agent and multi-functional technology, applied in the field of water-based drilling fluids, can solve problems such as failure to meet environmental protection requirements, toxicity, and farmers' reprimand, and achieve the effects of no environmental pollution, reduced filtration loss, and good anti-seize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

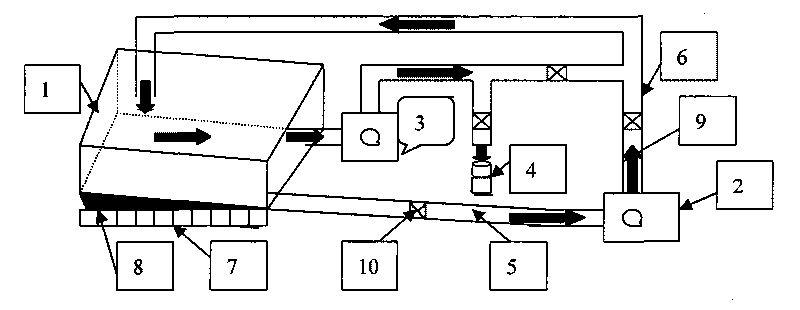

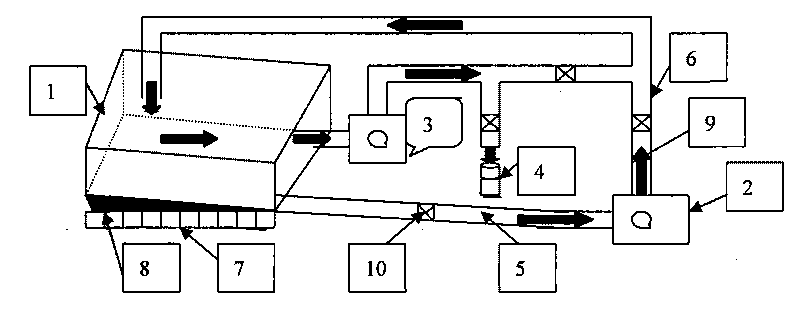

[0022] Example 1: Preparation method of multifunctional drilling fluid treatment agent MFA-2

[0023] First put 100g of water into the reaction tank 1, start the multi-stage pump 2, open the valve 10, the water enters the reaction tank 1 through the pump pipe 6 according to the circulation flow direction 9 from the inlet pump pipe 5, and slowly adds 3g of dispersing agent MV-CMC and 2g glue protection agent JT 888 ;After completely dissolving, add 3.75g of emulsifier OP-10 at one time, start the multi-stage pump for 2 cycles for 10 minutes, then slowly add 68g of liquid paraffin, emulsify for 30 minutes after adding, add the sample to water and stir until the liquid paraffin can be dissolved in water until it is dispersed; then add 2g of defoamer YHP-008 at one time, and continue to circulate for 5-10 minutes, take a sample and add it to water and stir until the sample can be dispersed in water without foaming; finally add 1g of 36% formaldehyde at one time, Recirculating for...

example 2

[0024] Example 2: Effect of MFA-2 in drilling fluid (see Table 2, Table 3)

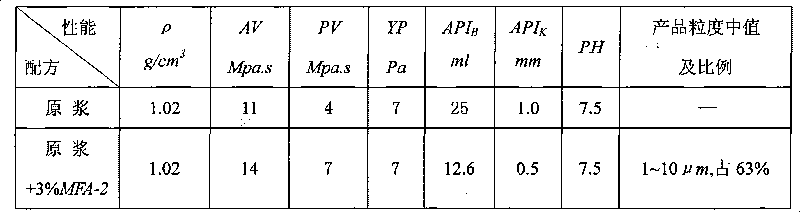

[0025] Table 2 MFA-2 drilling fluid properties

[0026]

[0027] Note: 1. The original slurry is 4% Anqiu secondary soil slurry. 2. Temperature measurement: 25°C.

[0028] Table 3 Other characteristics of MFA-2 drilling fluid

[0029]

[0030] Note: 1. Lubrication coefficient is measured by extreme pressure lubrication instrument; 2. Plugging capacity is measured by sand packing method, the condition is 500Psi (600Psi). 80℃ / 30min, and then the permeability K is measured with clean water under different pressures w ; 3. Recovery rate R 40 Choose 6-10 mesh Sichuan red layer soil, and pass 40 mesh to get the result.

[0031] It can be seen from the results in Table 2 and Table 3 that MFA-2 has a good fluid loss reduction effect, and the reduction rate can reach about 50% (addition amount 3%). MFA-2 is added into the original slurry as soft deformable particles, which can effectively seal the f...

example 3

[0032] Example 3: Fluorescence level, toxicity of MFA-2

[0033]Weigh 0.5g of the sample into a clean test tube, add 5ml of chloroform, stir slowly for 5 minutes, compare it with the standard colorimetric tube under the irradiation of a fluorescent lamp, and determine the fluorescence level of MFA-2. The measurement result is level 1, which can be seen The fluorescence level of MFA-2 is very low, far less than level 3, and it is a non-fluorescent level product (the fluorescence levels of sulfonated asphalt HL-II and SAS are much higher than level 10 and up to level 14 when detected by the same method), therefore, MFA -2 added to drilling fluid has no effect on geological logging, and can be used in all production wells and exploration wells.

[0034] Using GB / T13267-91 "Determination of Acute Toxicity of Water Quality Substances to Freshwater Fish", the acute toxicity of MFA-2 to goldfish was evaluated. This study was completed by the Sichuan Provincial Environmental Monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com