Modified sulphurized asphalt used for drilling fluid and preparation method thereof,

A technology of sulfonated asphalt and drilling fluid, which is applied in the direction of chemical instruments and methods, processing tar asphalt/petroleum asphalt/natural asphalt, drilling compositions, etc., which can solve unfavorable drilling operations, drilling fluid foaming, In order to improve the performance of high temperature and high pressure fluid loss, increase lubricity, inhibit expansion and dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

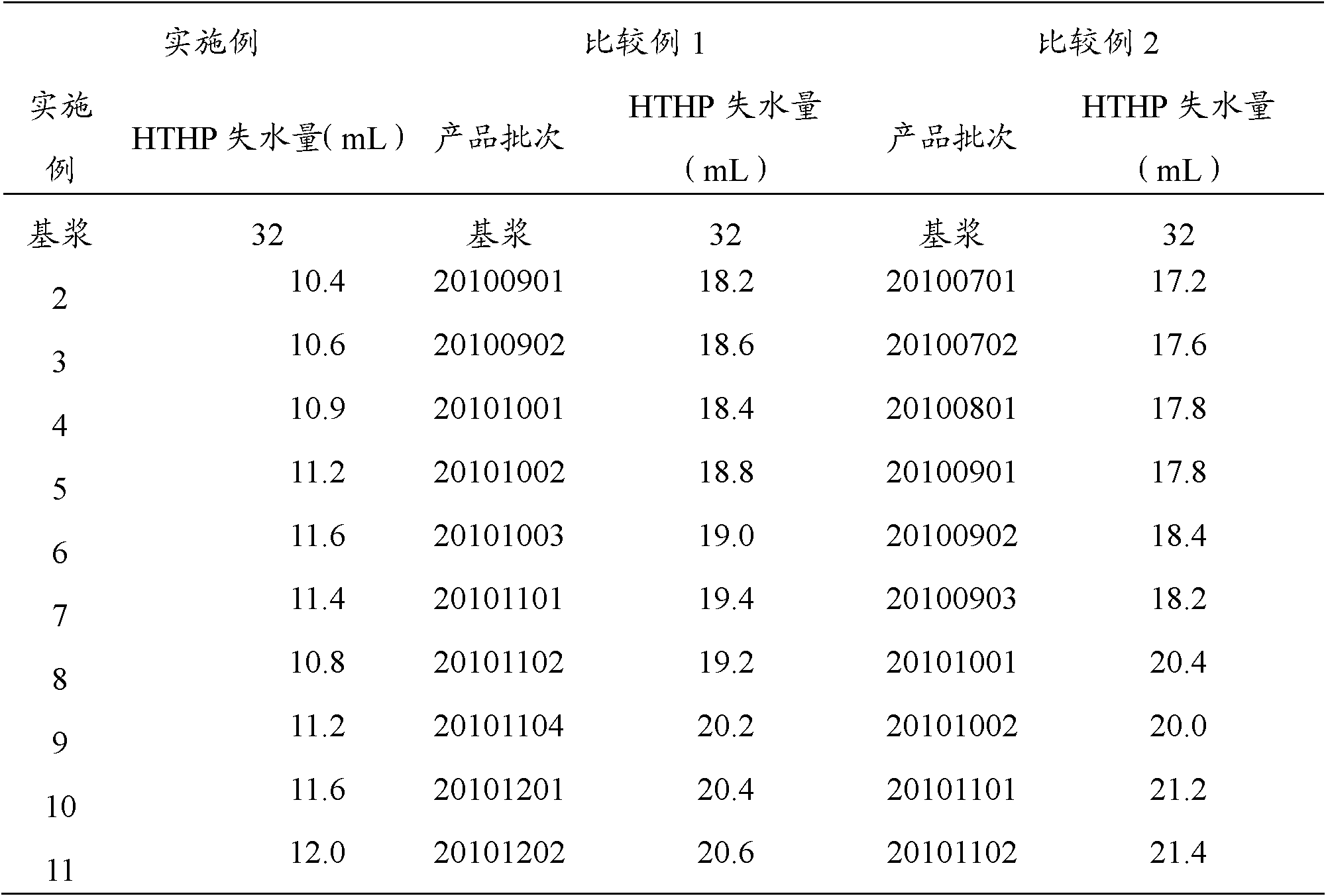

Examples

preparation example Construction

[0025] The present invention also provides a preparation method of modified sulfonated asphalt for drilling fluid, comprising the following steps:

[0026] a) mixing medium temperature coal tar pitch, kerosene and fuming sulfuric acid to obtain sulfonated medium temperature coal tar pitch after reaction;

[0027] b) mixing the sulfonated medium-temperature coal tar pitch and high-temperature hard coal tar pitch to obtain a modified sulfonated pitch for drilling fluid.

[0028] The invention uses medium-temperature coal tar pitch and high-temperature hard coal pitch as raw materials to prepare modified sulfonated pitch, and the obtained modified sulfonated pitch has good high-temperature and high-pressure fluid loss reduction performance.

[0029] In the present invention, the softening point of the medium temperature coal tar pitch is preferably 75°C to 95°C, more preferably 80°C to 90°C; the dissolution rate of the medium temperature coal tar pitch in carbon tetrachloride is ...

Embodiment 1

[0043] Add 14g of benchmark sodium bentonite to 350mL of distilled water, stir at a speed of 11000r / min for 20min, scrape off the adherents adhering to the container wall with a glass rod during the stirring process; after stirring, seal the obtained mixture for 24h, and then Add 7.0g of iron-chromium lignosulfonate and 7.0g of evaluation soil, stir for 30min, adjust the pH value to 10 with 20% sodium hydroxide solution, stir at 11000r / min for 20min to obtain the base slurry.

Embodiment 2

[0045] Pulverize the medium-temperature coal tar pitch to 20 mesh, and pass through a 20-mesh standard inspection sieve to obtain medium-temperature coal tar pitch particles; add 150 g of the medium-temperature coal tar pitch to the kneader, add 5 g of kerosene under stirring, and knead for 10 minutes; Add 45gSO under the condition 3 Fuming sulfuric acid with a content of 25wt%, kneading for 30min; the obtained reaction mixture was naturally air-dried and crushed to 20 mesh, and passed through a 20 mesh standard inspection sieve to obtain acidic sulfonated asphalt particles; Add the acidic sulfonated asphalt particles into the sodium hydroxide solution, stir and neutralize for 30 minutes to obtain the sulfonated asphalt colloid; dry the sulfonated asphalt colloid in a drying room at 140°C for 48 hours, crush it to 40 mesh, pass 40-mesh standard inspection sieve to obtain sulfonated asphalt particles;

[0046] Crush the high-temperature hard coal tar pitch to 40 mesh, and pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com