Sodium silicate cementing pre-fluid

A technology of cementing pre-fluid and sodium silicate aqueous solution, applied in chemical instruments and methods, drilling composition and other directions, can solve the problem of inability to meet the requirements of oil and gas well drilling and production operations, low return of cement slurry, and annular channeling And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Indoor test:

[0022] 1) Prepare flushing solution: flushing agent BCS-010L: 3.5wt.%, the rest fresh water,

[0023] 2) Prepare sodium silicate solution: fresh water: 74.7%, sodium silicate: 25%, defoamer G603: 0.3%;

[0024] 3) Prepare spacer: fresh water, suspending agent BCS040S: 5%, diluent BCS-021L: 1%, defoamer G603: 0.3%, silicon powder aggravated to 1.25g / cm 3 ;

[0025] Cementing cement slurry: "B" grade oil well cement, lightening agent BXE-600S: 23%, suspension stabilizer GW-4: 0.04%, micro silicon: 5%, fluid loss reducer BXF-200L: 3%, anti-channeling Agent BCG-200L: 3.5%, defoamer G603:: 0.2%

[0026] Preparation: calcium chloride: 0.3g×3 parts

[0027] Indoor test content and method:

[0028] (1) Normal temperature performance of pre-fluid.

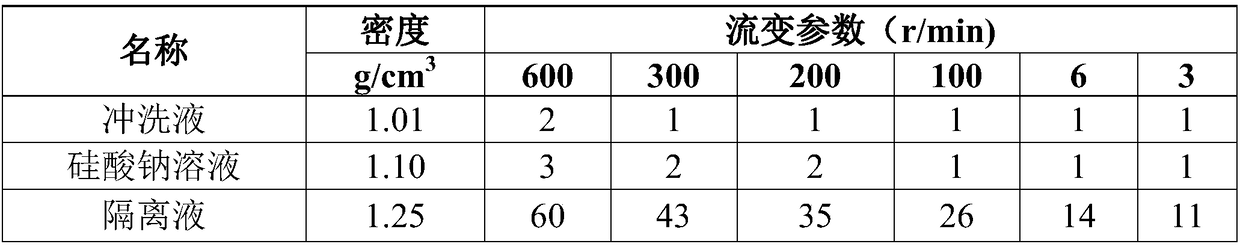

[0029] Table 1. Rheology of front fluid at room temperature

[0030]

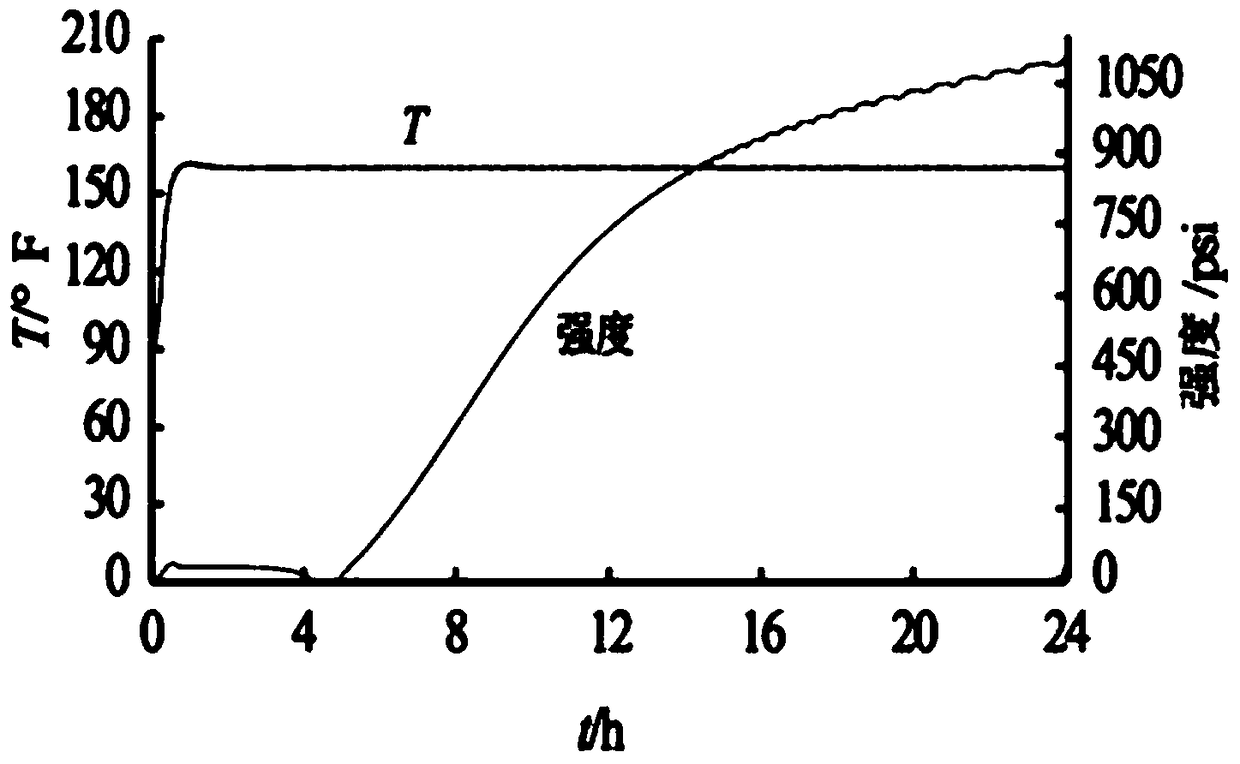

[0031] (2) High temperature performance of prefluid (test condition of 70°C).

[0032] Table 2 Rheological properties of pre-fluid at ro...

Embodiment 2

[0052] Under normal geological conditions, the pre-fluid system is mainly to improve the bonding of the cement interface, and also to prevent leakage.

[0053] 1) Prepare cementing flushing fluid: fresh water, flushing agent G603: 3.5%;

[0054] 2) Prepare sodium silicate solution: fresh water: 74.7%, sodium silicate: 25%, defoamer G603: 0.3%;

[0055] 3) Prepare weighted spacer: fresh water, suspending agent BCS040S: 5%, diluent BCS-021L: 1%, defoamer G603: 0.3%, silicon powder weighting agent to 1.25g / cm 3 .

[0056] 4) Preparation of cement slurry: "B" grade oil well cement, silica fume: 45%, lightening agent BXE-600S: 23%, stabilizer GW-4: 0.06%, micro silicon: 8%, fluid loss reducer BXF-200L : 3%, anti-air channeling agent BCG-200L: 3.5%, defoamer G603: 0.2%

[0057] According to the pre-fluid 14m on site 3 design, where the cleaning fluid 3.5m 3 , accounting for 25% by volume; sodium silicate solution 6.5m 3 , accounting for 46.4% by volume; spacer 4m 3 , accounti...

Embodiment 3

[0063] In the complex geological downhole conditions with both overflow and leakage, the pre-fluid system is mainly used for plugging and interface cementation.

[0064] 1) Prepare flushing type weighted isolation fluid: clear water, suspending agent BCS040S: 5%, flushing agent BCS-010L: 5%, thinner: 1.5%, defoamer G603: 0.25%, silicon powder weighting agent to balance the formation pressure desired density.

[0065] This spacer is a double-action spacer, which has dual functions of flushing and isolation. The reason why it is a flushing type aggravated spacer is that it adds a flushing agent on the premise of the isolation function, and at the same time plays a flushing role.

[0066] 2) Prepare sodium silicate solution: clear water, 55% sodium silicate, density 1.26g / cm 3 ;

[0067] 3) Preparation of spacer fluid: clear water, suspending agent BCS040S: 5%, diluent BCS-021L: 1.3%, defoamer G603: 0.25%, silicon powder weighting agent to increase the density required to balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com