Hairiness smoother for shuttleless loom

A shuttleless loom and dressing technology, applied in the field of textile equipment accessories and hairiness dressings, can solve the problems of high three-section height, high production cost, high unevenness, etc., to increase strength and softness, and reduce the rate of broken ends. Extremely high, highly effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

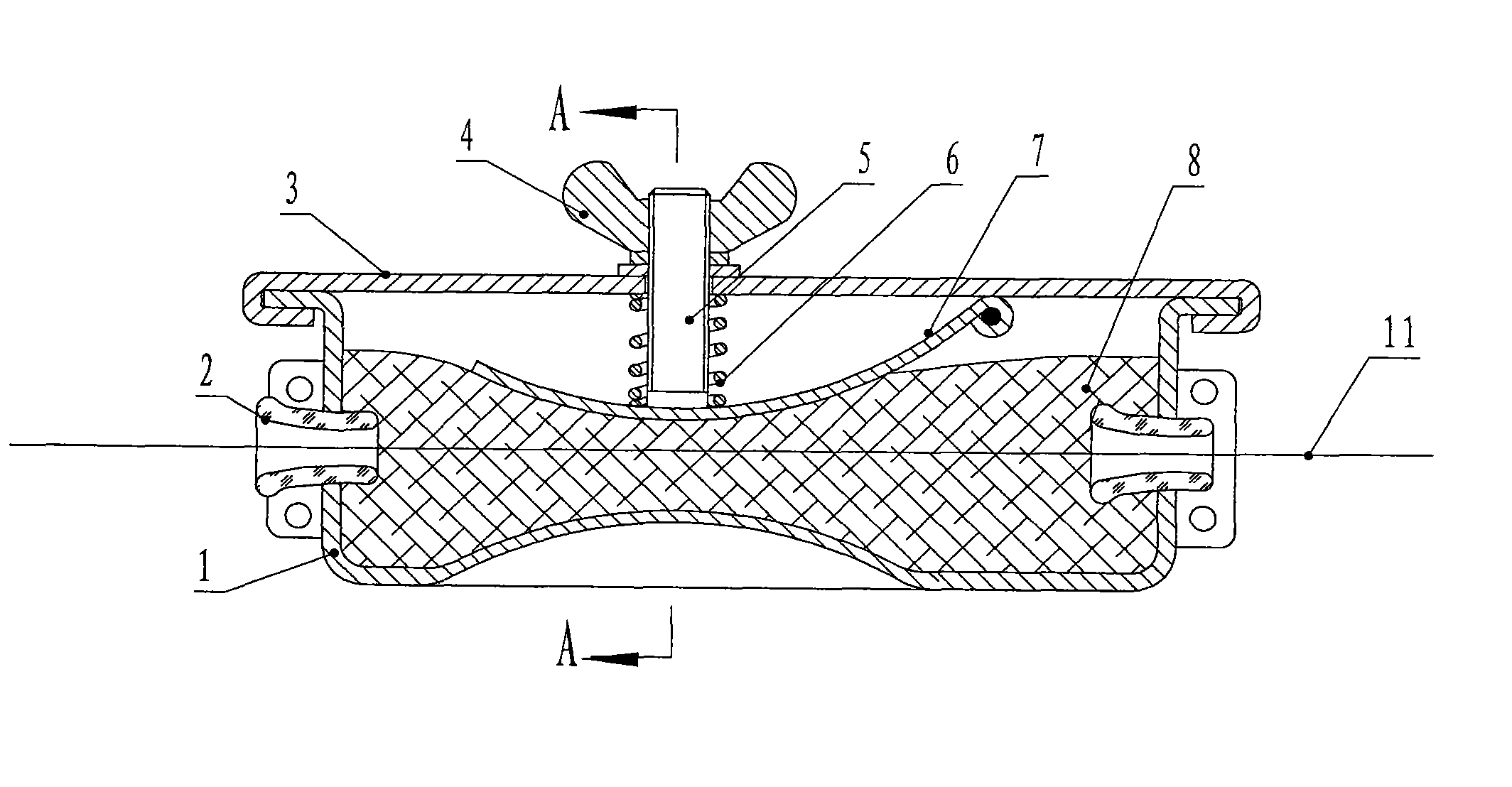

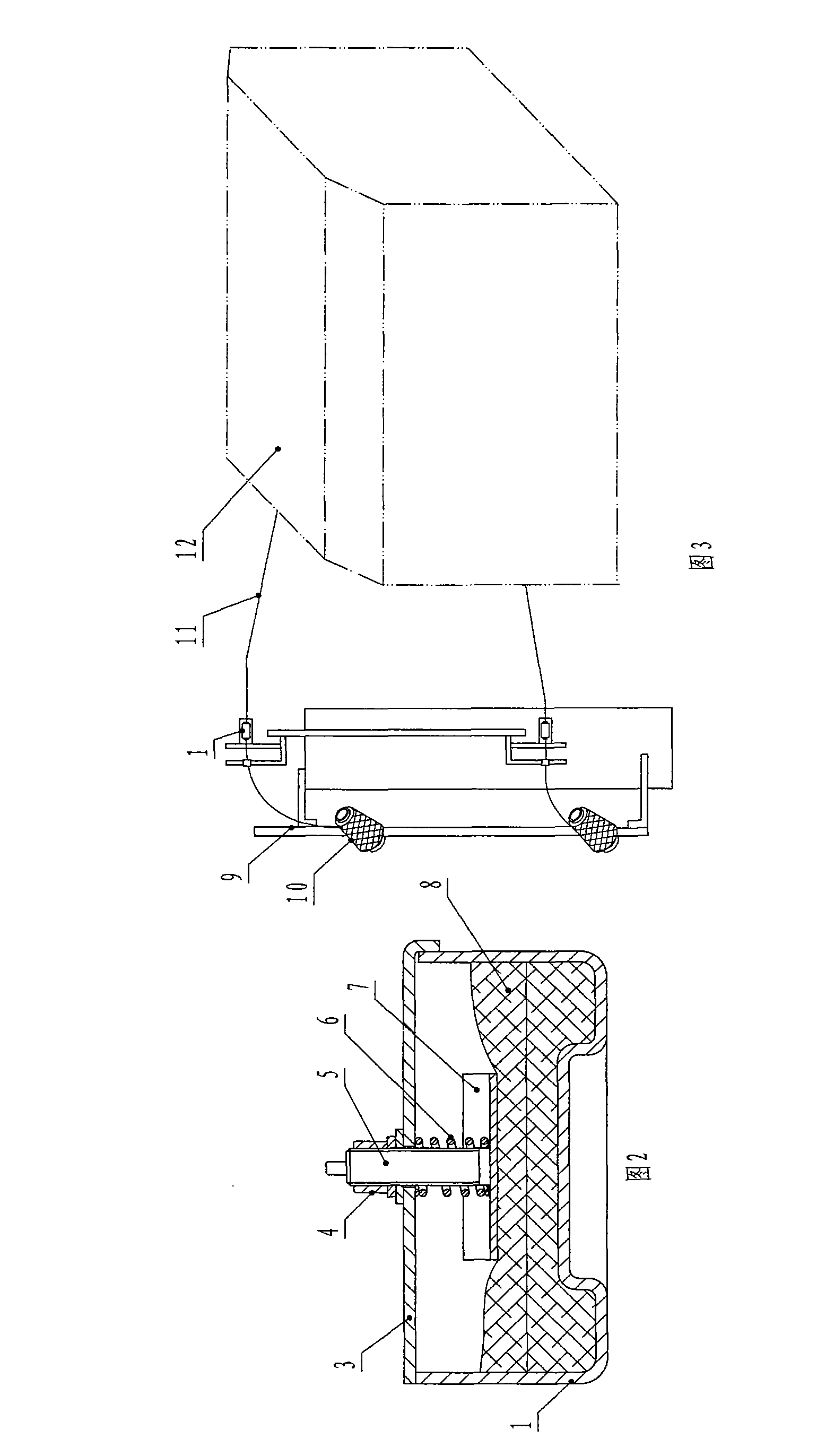

[0013] see figure 1 , figure 2 , The present invention consists of a box body 1, an upper cover 3, a pressure regulating mechanism, a linoleum pad 8 and a porcelain eye 2. The upper cover and the box body are connected by inserting, which can not only ensure reliable connection, but also facilitate the opening of the upper cover. The porcelain eyes are arranged at both ends of the shell, and the linoleum pad is located in the shell in two layers. The pressure regulating mechanism presses against the top of the linoleum pad to exert pressure on the linoleum pad, and the weft yarn 11 passes through the linoleum pad. The pressure regulating mechanism is composed of an adjusting nut 4, an adjusting rod 5, a spring 6 and a pressing plate 7. The adjusting rod passes through the upper cover, its upper part is screwed with the adjusting nut, the lower end is welded with the pressing plate, and the spring is set in the middle of the adjusting rod.

[0014] see figure 1 , image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com