Method for reducing viscosity of crude oil

A crude oil and viscosity technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problems of difficult popularization and application, increase investment and operation and maintenance costs, etc., and achieve convenient operation, investment and operation costs. Low, EOR effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

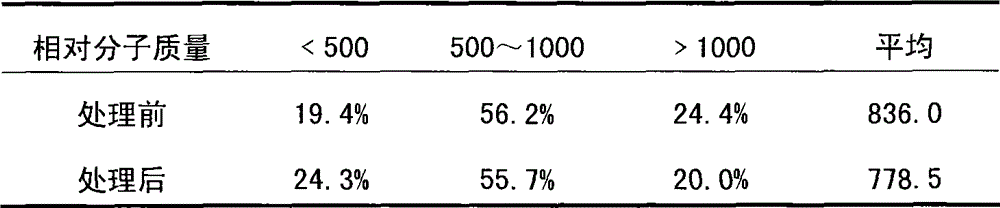

[0025] Take a certain kinematic viscosity (50°C) as 722.6mm 2 20g of crude oil per s and 180g of water with a pH of 5.5 were placed in a three-necked flask, and the magnetic stirrer was started, and 4.0mL of FeSO with a concentration of 50g / L 4 Add the aqueous solution to the three-necked flask, add 1.0ml of hydrogen peroxide solution with a concentration of 90g / L after 5min, stop stirring after reacting at 50°C for 4h, let it stand for oil-water separation, take the upper crude oil to measure the viscosity, the viscosity is 584.4mm 2 / s, the viscosity reduction rate is 19.1%.

Embodiment 2

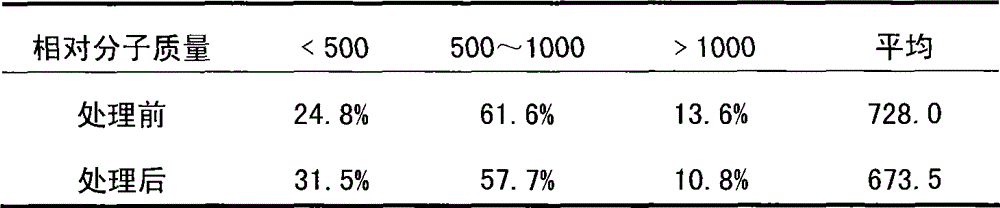

[0027] Take a certain kinematic viscosity (50°C) as 1164.0mm 2 20g of crude oil per s and 180g of water with a pH of 4.0 are placed in a three-necked flask, and the magnetic stirrer is started, and 4.0mL of Fe(NO with a concentration of 40g / L 3 ) 2 Add the aqueous solution to the three-necked flask, add 1.0mL of potassium hypochlorite solution with a concentration of 54g / L after 5min, stop stirring after reacting at 80°C for 6h, let it stand for oil-water separation, take the upper crude oil to measure the viscosity, the viscosity is 907.9mm 2 / s, the viscosity reduction rate is 22.0%.

Embodiment 3

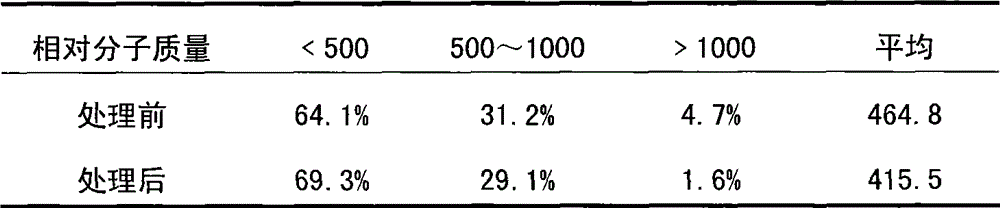

[0029] Take a certain kinematic viscosity (50°C) as 186.6mm 2 20g of crude oil per s and 180g of water with a pH of 6.0 were placed in a three-necked flask, and the magnetic stirrer was started, and 1.0mL of FeSO with a concentration of 36g / L 4 Add the aqueous solution to the three-necked flask, add 1.0mL of sodium hypochlorite solution with a concentration of 18g / L after 5min, stop stirring after reacting at room temperature for 2h, let it stand for oil-water separation, take the upper crude oil to measure the viscosity, the viscosity is 152.4mm 2 / s, the viscosity reduction rate is 17.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com