Scraper type cantilever conveyer

A conveyor and scraper-type technology, applied in the field of scraper-type cantilever conveyors, can solve the problems of no coal safety certification and low material transportation efficiency, and achieve the effect of easy operation, high transfer efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

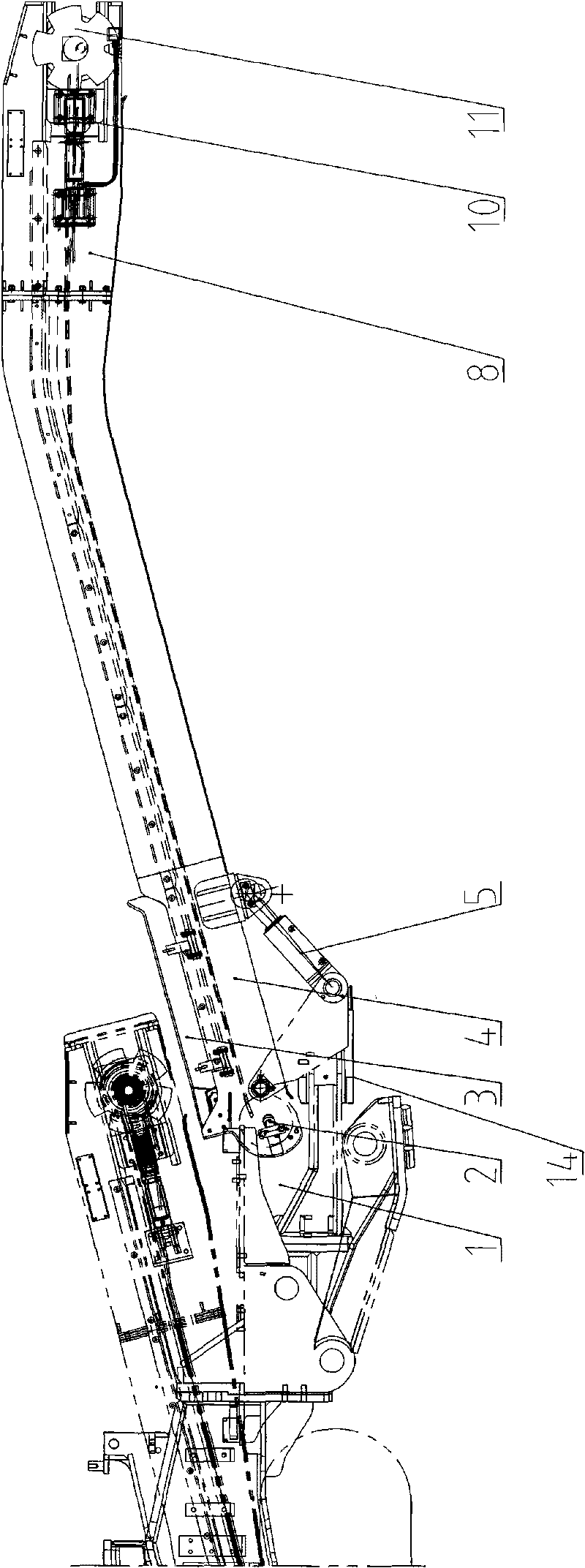

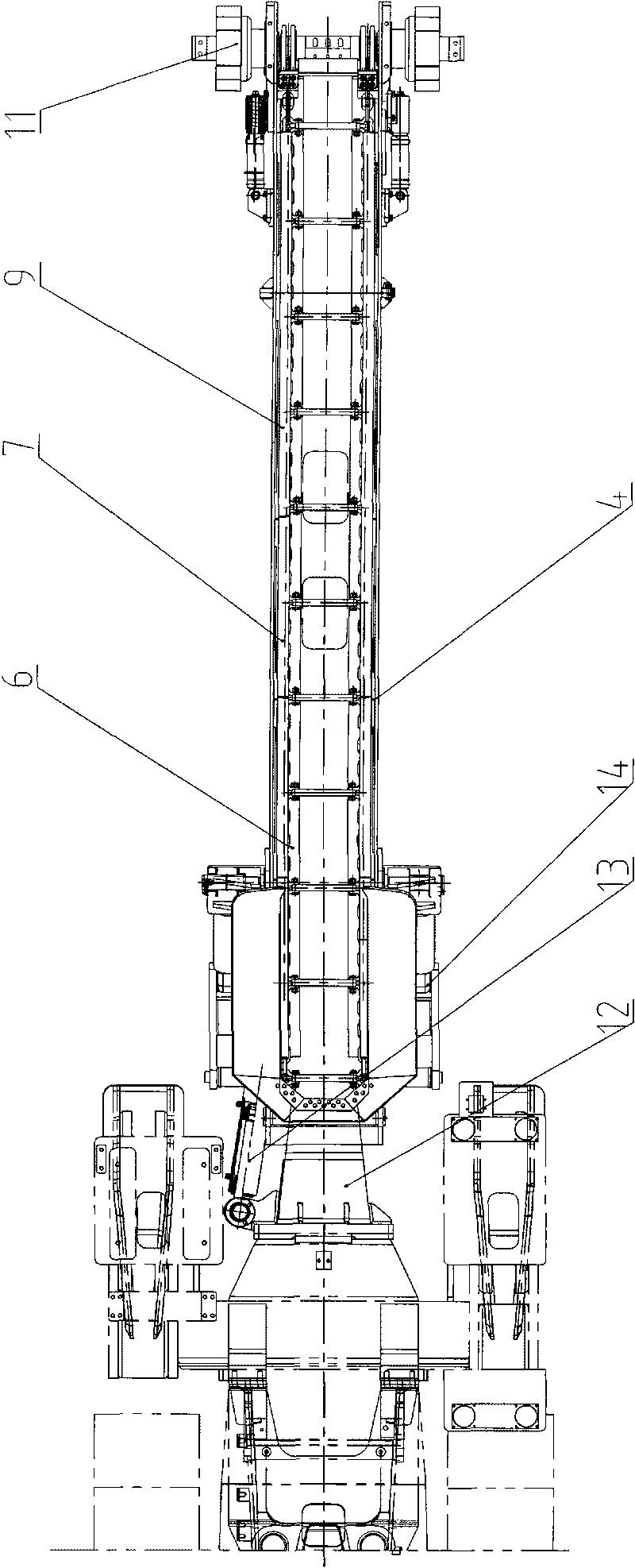

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

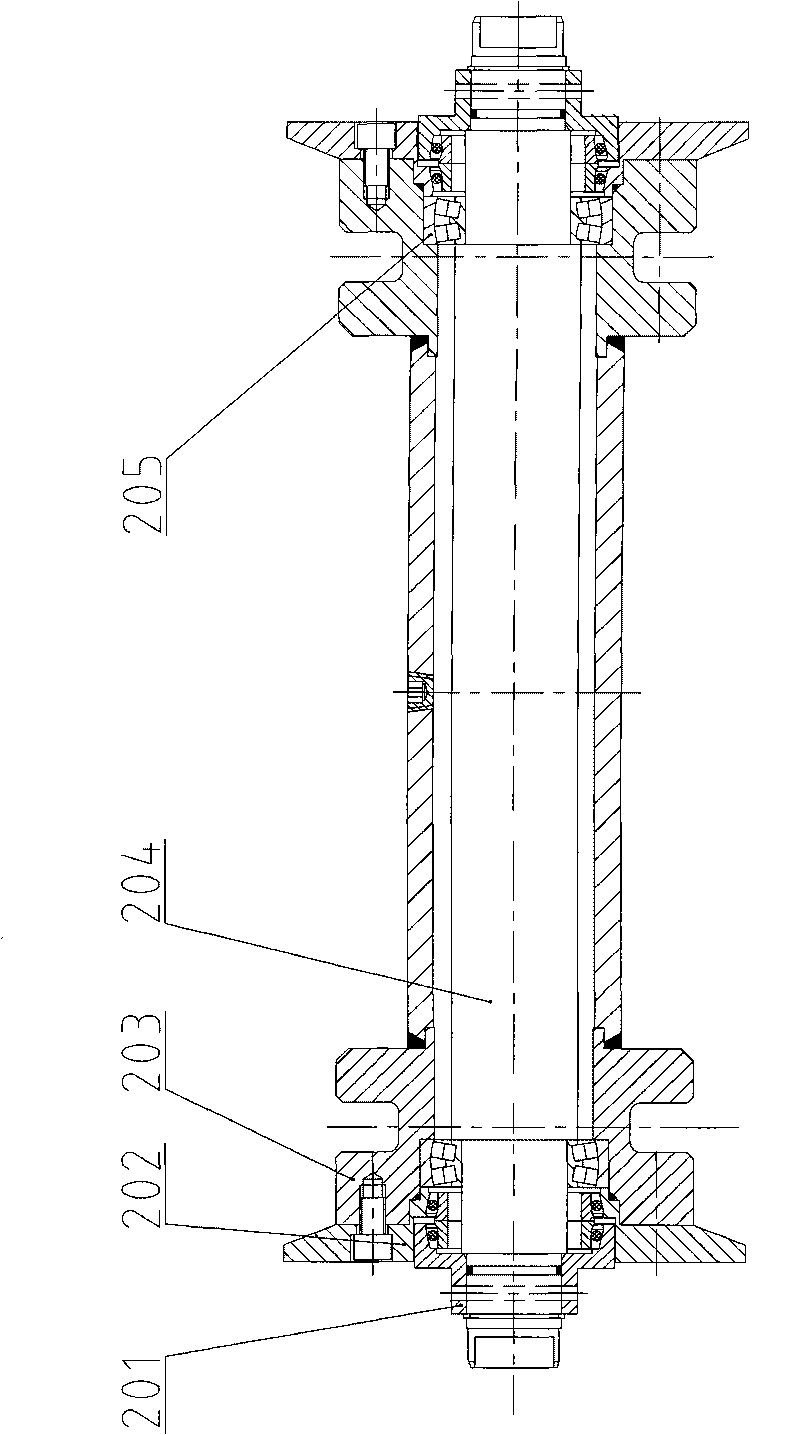

[0037] Such as Figure 1(a)-Figure 1(b) As shown, the present invention is a scraper type cantilever conveyor, which includes: roadheader 1, driven device 2, hopper 3, front chute 4, lifting cylinder 5, scraper chain assembly 6, pressure plate 7, rear chute 8, Pressing block 9, tensioning device 10, driving device 11, connecting frame 12, rotary oil cylinder 13, second conveyor rotary table 14, etc. The specific structure is as follows:

[0038] The front chute 4 is connected to the rear second conveyor turntable 14 of the roadheader 1, one end of the lifting cylinder 5 of the roadheader 1 is hinged to the second conveyor turntable 14 of the roadheader, and the other end is hinged to the front chute 4 to control the movement of the lift cylinder 5 The stroke can realize the adjustment of the tail height of the scraper conveyor. One end of the rotary cylinder 13 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com