Internal combustion engine

An internal combustion engine and recirculation technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve complex problems, achieve the effects of simplifying the structure, realizing NOx emissions, and reducing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

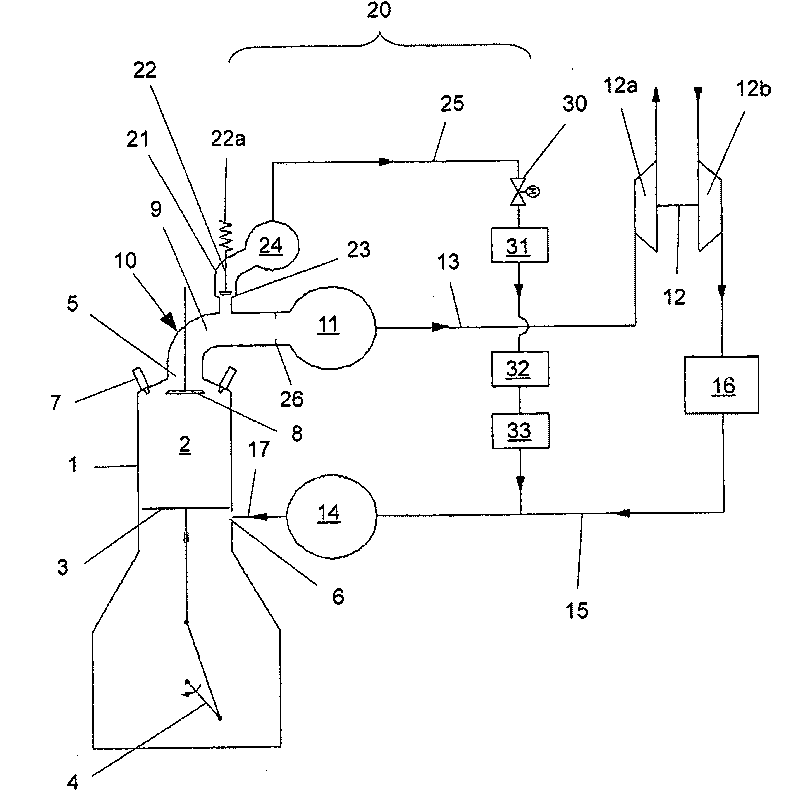

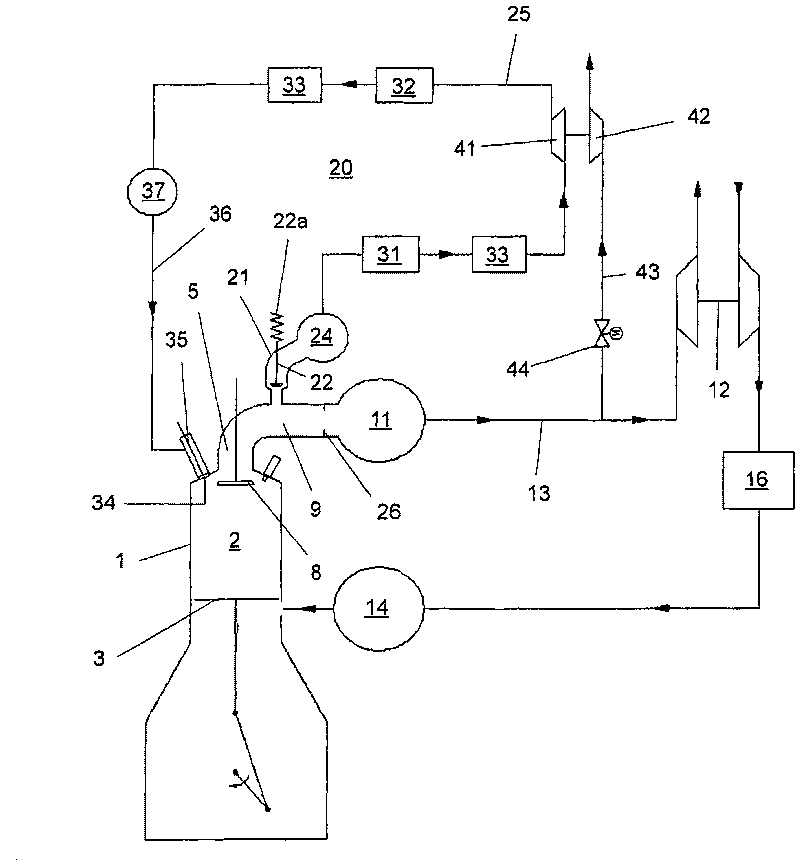

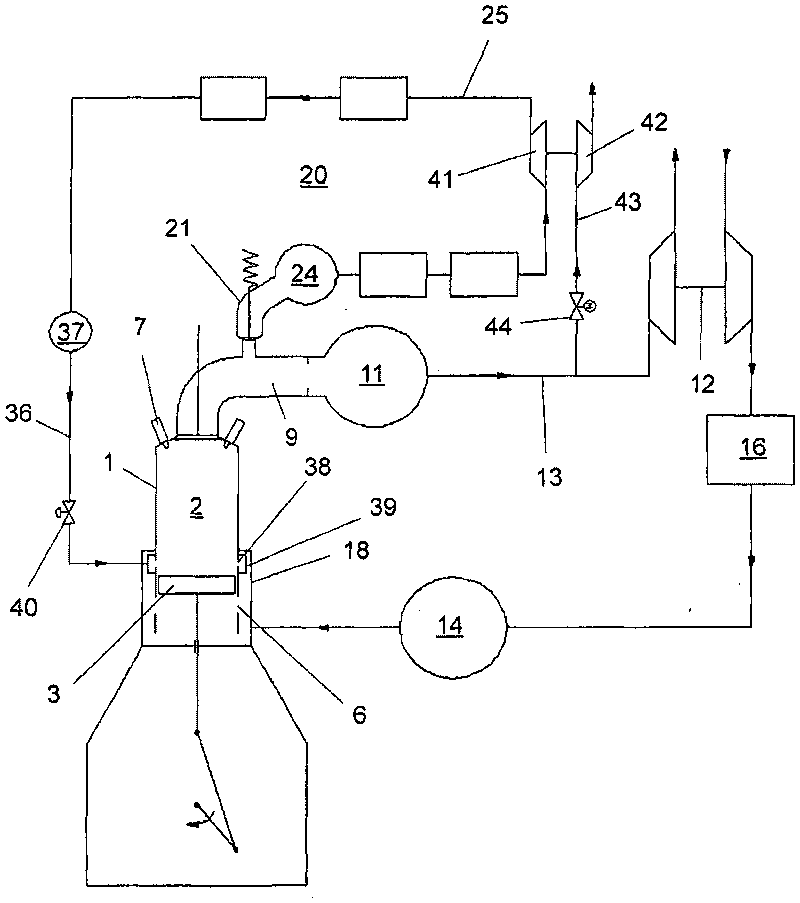

[0029] The main field of application of the invention is large diesel engines, in particular two-stroke large diesel engines, such as large diesel engines used as drives for ships or stationary power plants. Each of the illustrated embodiments is based on a two-stroke large diesel engine. This is only the preferred application. However, the present invention is not limited thereto.

[0030] Such engines typically include multiple cylinders. exist Figures 1 to 3 One such cylinder 1 is shown in each case. The cylinder contains a working chamber 2 acting as a combustion chamber, which is delimited by a reciprocating, here vertically moving, piston 3 . Piston 3 cooperates with a crankshaft 4 via conventional transmission elements. In each working stroke, in order to realize the combustion process, the working chamber 2 is loaded with fuel and contains oxygen (O 2 ) of the scavenging gas. The exhaust gas formed by the combustion is discharged through the exhaust gas outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com