Independent low-pressure heater and drainage pump flow soft measurement-based method for measuring and calculating pump efficiency

A technology of drainage pump and soft measurement, applied in the field of soft measurement, can solve the problems of manpower and material resources, time-consuming and labor-intensive of drainage pump, influence measurement of output power of drainage pump, etc., and achieve the effect of reducing measurement cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

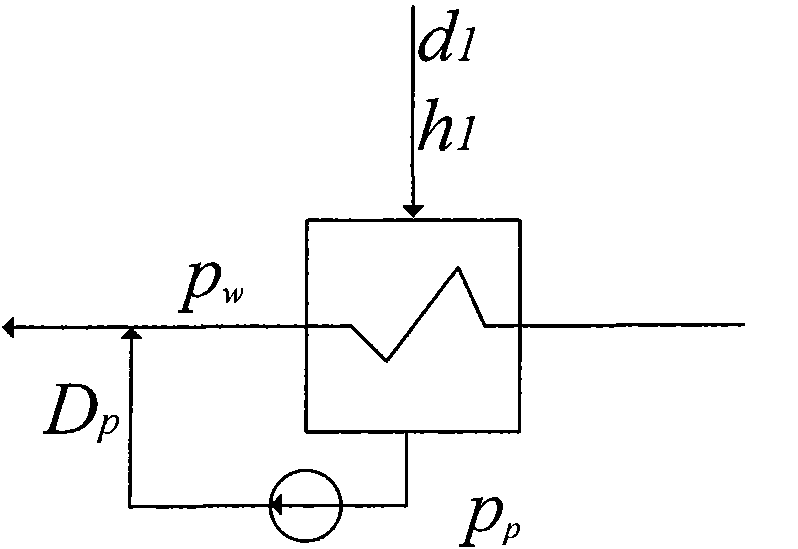

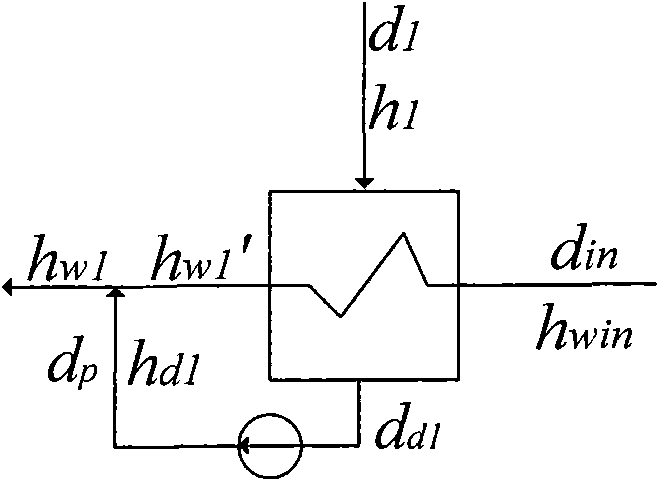

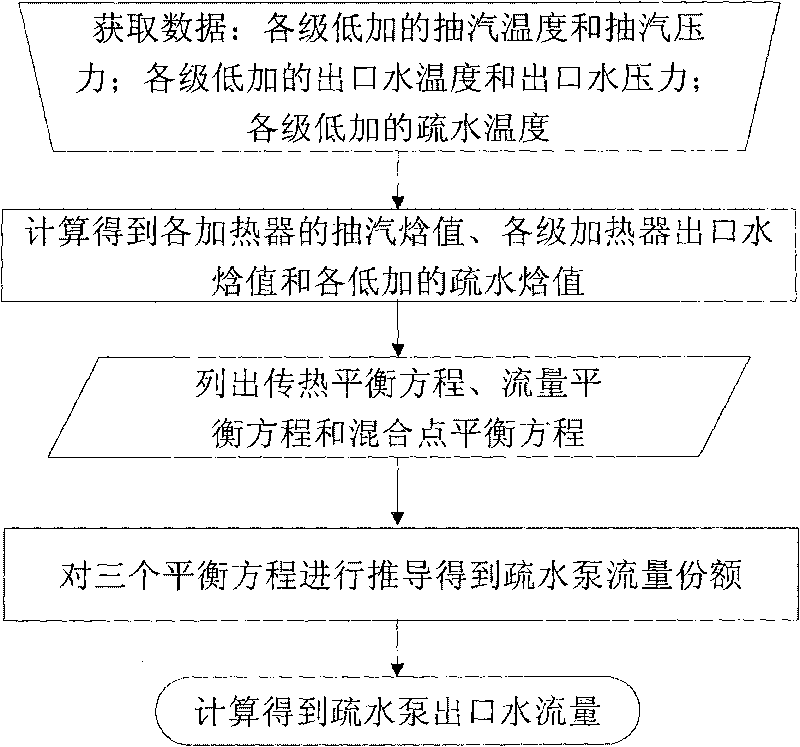

[0039] A pump efficiency calculation method based on the soft measurement of the flow rate of the independent low sump drain pump, which consists of an independent low sump and a drain pump, and no other drain enters the low sump. Among them, the hydrophobic pump is used to mix the hydrophobic water of the heater with the feed water at the outlet of the heater, and the algorithm steps are as follows:

[0040] Step 1: Obtain the water pressure p at the outlet of the heater with the drain pump from the database of the plant-level monitoring information system SIS or the distributed control system DCS of the thermal power plant w;Get the inlet water temperature t of the drain pump p , calculate the inlet water pressure p of the drain pump p and hydrophobic average specific volume v p , calculate the pressure difference Δp of the drain pump as the water pressure p at the outlet of the heater with the drain pump w Inlet water pressure p with the drain pump p The difference, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com