Production technology for heavy type super-long shaft

A production process and super-long shaft technology, applied in the production process of heavy and super-long shafts, can solve the problems of affecting performance indicators, low work efficiency, low output, etc., to improve the quality of forgings, improve productivity, and smooth and reasonable material flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

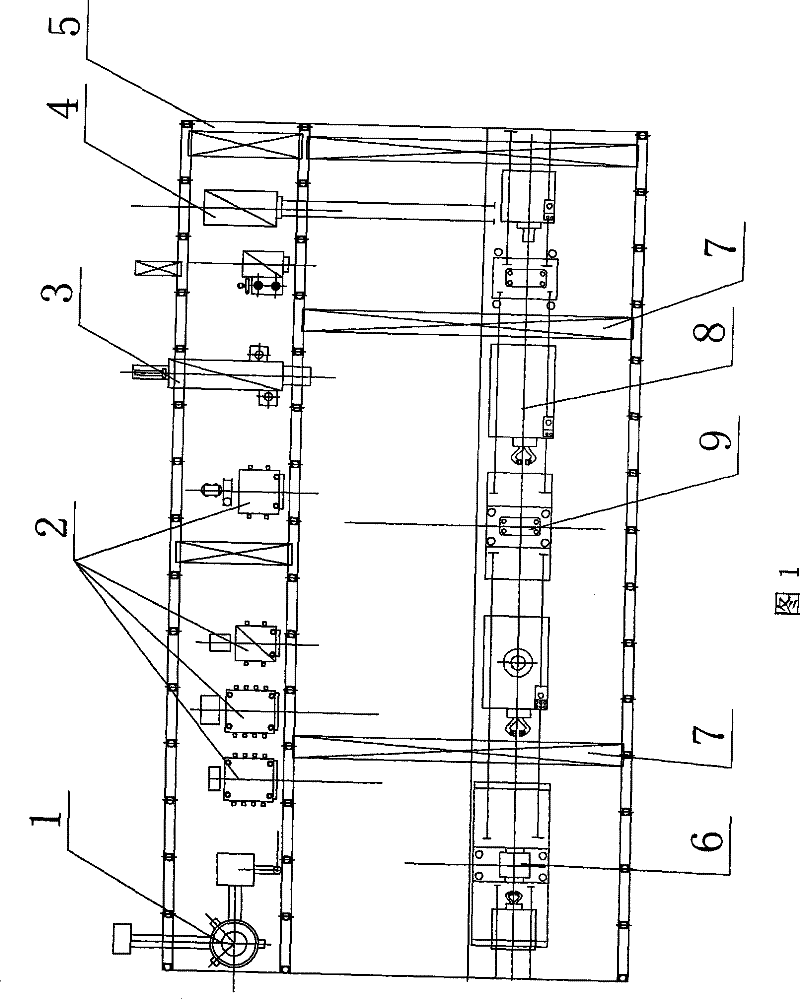

[0023] The production process of heavy-duty super-long shafts, the process includes material preparation, heating, forging, cooling or heat treatment, and finished product inspection process. Through the reasonable arrangement of equipment, this process makes the various processes closely cooperate and connect reasonably. The conversion between small processes improves work efficiency and reduces energy loss; see figure 1 , the heating equipment and the slow cooling pit are arranged in a line, and the forging equipment is arranged in a line to form two parallel production compact layouts, and the steel ingots or forgings are directly transported by cranes.

[0024] Optional equipment:

[0025] 1) Crane: material delivery

[0026] 2) Heating equipment: continuous gas heating furnace and semi-gas heating furnace are arranged in one line;

[0027] 3) Forging equipment: two hydraulic presses, one electro-hydraulic hammer, and the three equipments are arranged in a line;

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com