Push-in type quick pipe connecting piece

A push-in, pipe-connecting technology, used in mechanical equipment, couplings, etc., can solve the problems of slow production process, water leakage, and increased pipe pressure of claw connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

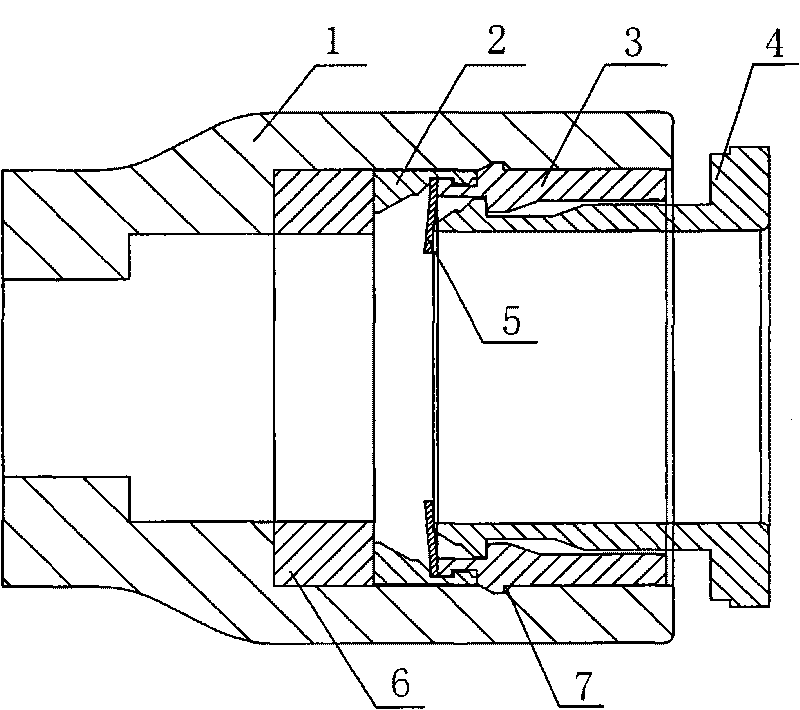

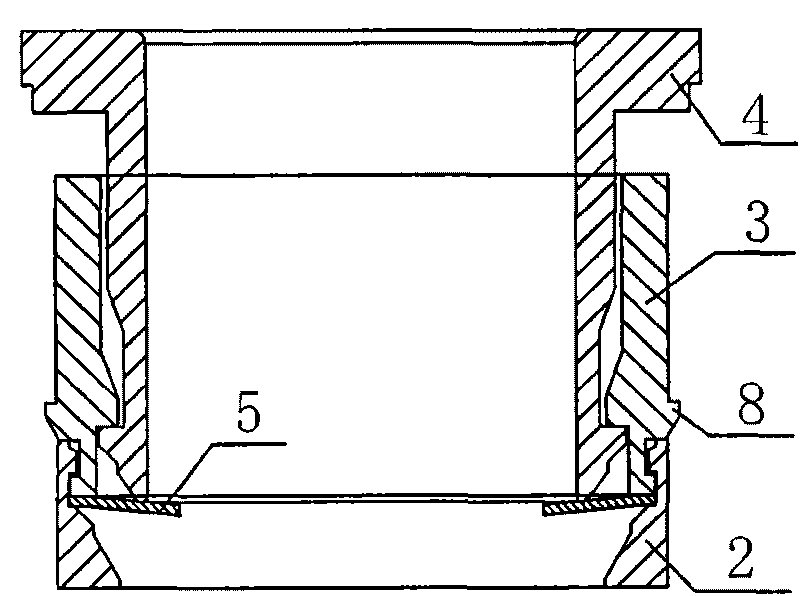

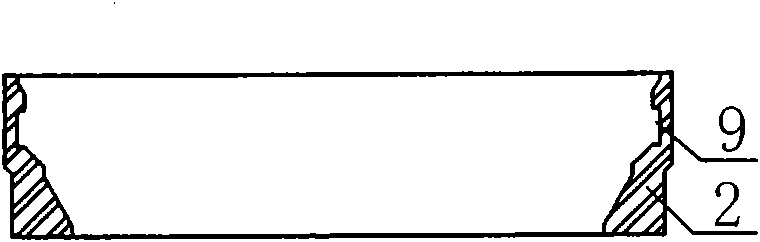

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

[0022] As shown in the figure, the push-in quick pipe connector includes a body 1, and a sealing ring 6 and a pipe locking device are sequentially embedded in the body 1. The pipe locking device and the sealing ring 6 are crimped and fitted. There is a groove 7, and the outer wall of the pipeline sealing device is provided with a protrusion 8 that matches the groove 7, and the protrusion 8 is engaged with the groove 7. Specifically, the outer wall of the fixing ring 3 is provided with a protrusion 8, and the protrusion 8 The block 8 is clamped and matched with the groove 7 on the inner wall of the body 1; the pipe locking device is composed of a claw piece fixing frame 2, a claw piece 5, a fixing ring 3 and a buckle 4, and the claw piece 5 is set to 10 according to the size of the body 1 Claws or more than 10 claws, the claw piece 5 is placed on the claw piece fixing frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com