Static demarcating method of belt scale

A technology of static calibration and belt scales, applied in the direction of weighing equipment testing/calibration, can solve the problems of time-consuming and labor-consuming, low operation efficiency, large investment, etc., and achieve the effect of easy cost and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

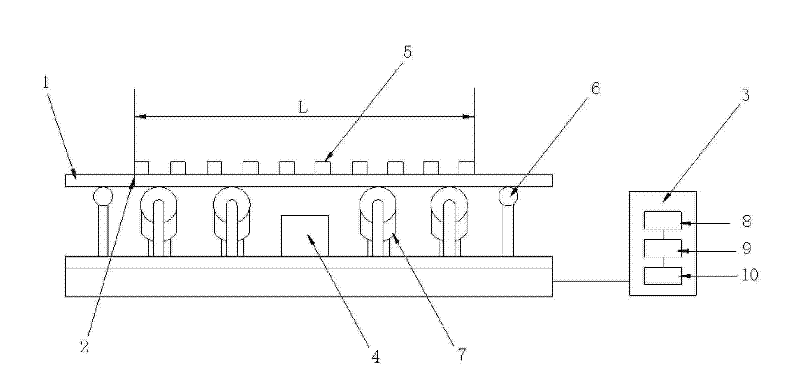

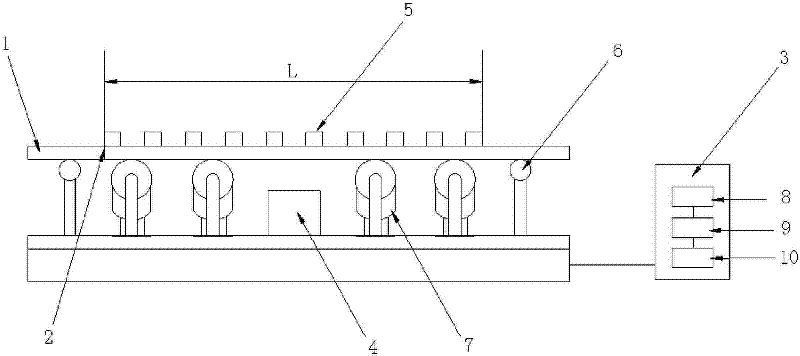

[0029] Embodiment 1: as figure 1 As shown, in order to realize the device structure of the inventive method to comprise basic belt scale assembly and weight 5, basic belt scale assembly comprises belt scale frame body, the load-measuring bridge frame 7 that is contained on the belt scale frame body, load cell 4 , Speed measuring drum 6 and conveyor belt 1, digital brushless pulse generator is housed in the speed measuring drum 6. Mark an empty belt section L from A to B on the conveyor belt 1 with a scribe line, and mark a scribe line on the belt scale frame below the corresponding position of A as the fixed-point reference object 2 . The basic assembly of the belt scale also includes a computer integrator 3, which is provided with a display 8, a CPU 9 and a memory 10 and the like.

[0030] With above-mentioned hardware equipment, set forth below the static calibration method of a kind of belt scale of the present invention, the calibration of whole belt scale: namely the p...

Embodiment 2

[0042] Embodiment 2: as figure 1 As shown, the calibration steps 1) and 2) of the speed signal can also be obtained by calculating the total pulse number P and the drum pulley circumference through the total pulse number P on the actual speed measuring drum 6 and the diameter D of the drum pulley on the speed measuring drum 6 Long L.

[0043] All the other are with embodiment 1.

Embodiment 3

[0044] Embodiment 3: as figure 1 As shown, the calibration steps 2) and 3) of the force signal can also be to use a weight 5 to be placed multiple times at intervals per unit length on the measurement section of the entire conveyor belt 1, and the number of times is generally controlled to about 30 times, which is limited according to specific circumstances. , the position of the head and tail weights is not less than 1 meter, and then the computer calculator 3 is used to calculate the actual measurement results of the force signal to obtain the mass PS per meter and the sampling value S2.

[0045] All the other are with embodiment 2.

[0046] The advantage of using the method of the present invention for calibration: the only foreign object used in the whole set of calibration methods is the standard weight, which is a common thing in our daily life, easy to obtain materials, low cost and can be reused. In the calibration method, the proportional coefficient R of the force s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com