Concrete pipe cathode protection testing probe and testing method

A concrete pipe and cathodic protection technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inaccurate judgment of cathodic protection effect, difficult natural corrosion potential, large IR drop, etc., to achieve feasible process plan and easy quality Control and eliminate the effect of IR drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

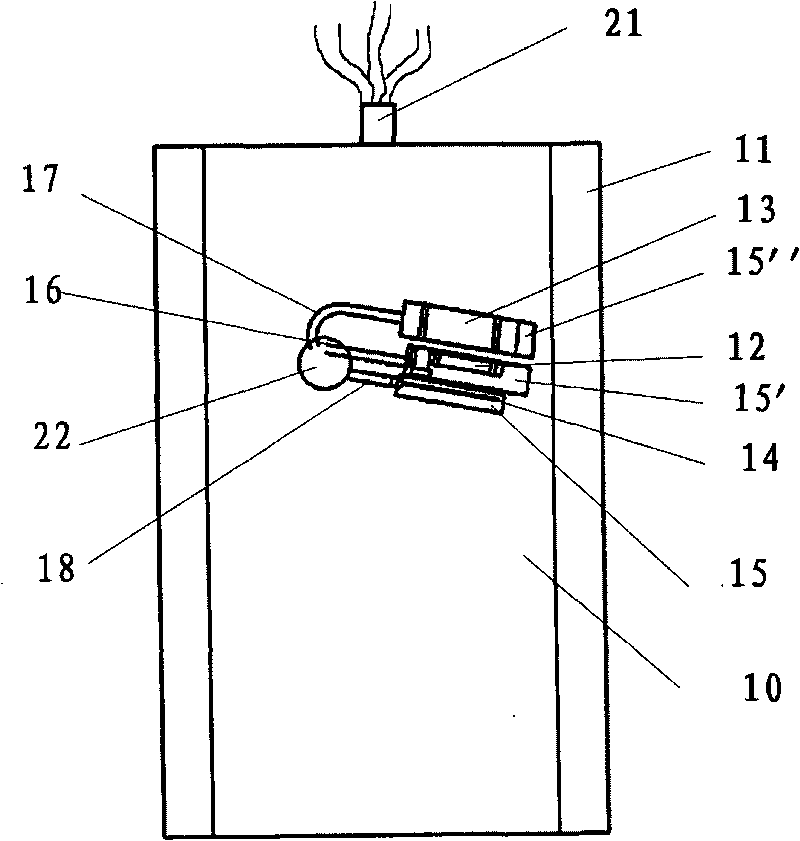

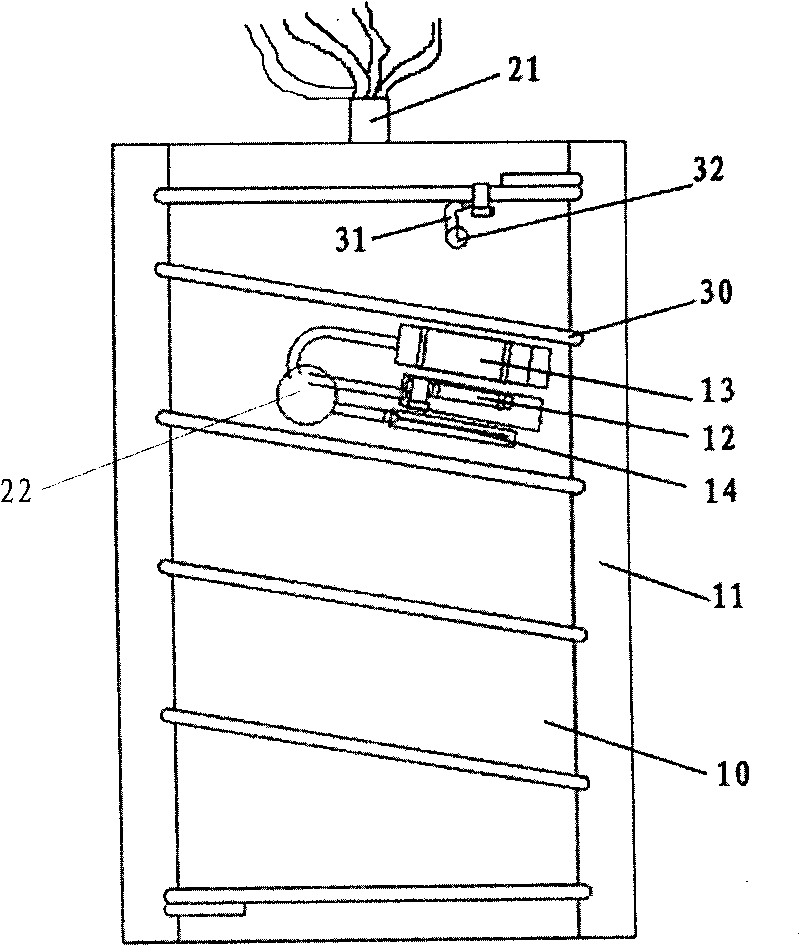

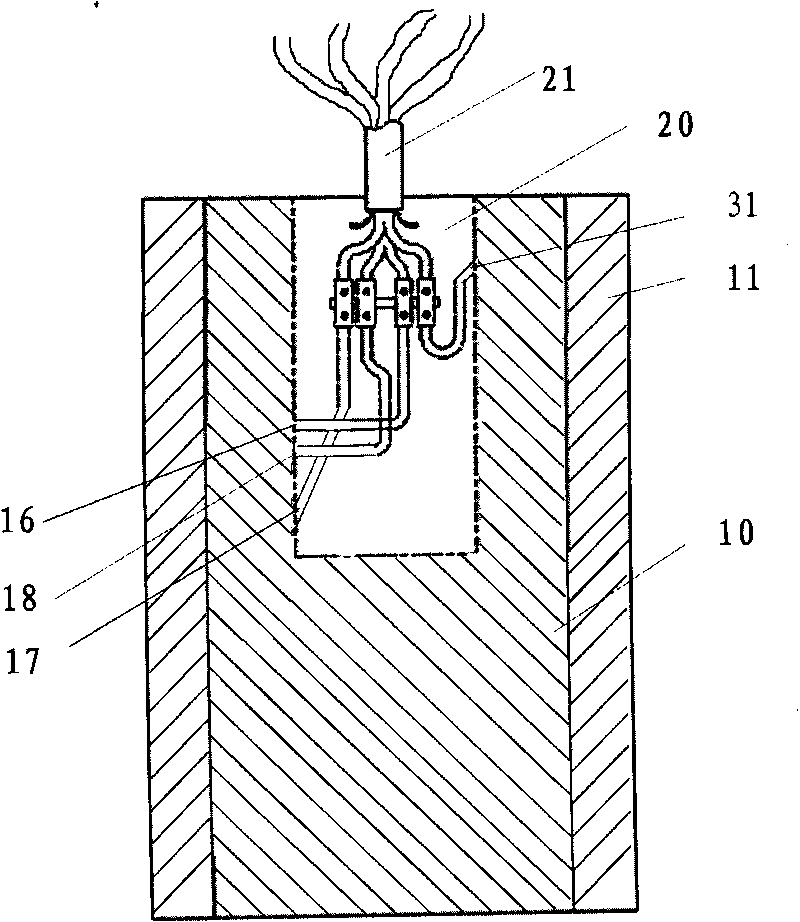

[0027] (1) The concrete core mold has been processed and made. The concrete core to be made has a diameter of 150mm and a height of 300mm, and the inside is a cylindrical cavity with a diameter of 75mm and a height of 150mm;

[0028] (2) According to the mechanical performance requirements of the concrete probe structure, a concrete vibration structure compaction bench is established. Put a certain proportion of cement, sand and stones into the mold, vibrate and compact in the vibrating table, and demould after a certain period of time;

[0029] (3) Establish a concrete core curing room with constant temperature and humidity, and place the concrete core in the curing room for curing until the required strength is reached;

[0030] (4) Bending the prestressed steel wire with a diameter of 5mm to form the structural shape of the prestressed steel wire in the concrete. It is worth noting that in order not to damage the material properties, no heat treatment can be performed duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com