Antistatic optical film

An antistatic and optical film technology, applied in the field of optical film, can solve the problems of reducing the impedance value of the antistatic layer, harming operators, low impedance, and one side being too high, so as to improve the antistatic effect, strengthen the antistatic effect, and improve the antistatic effect. Antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

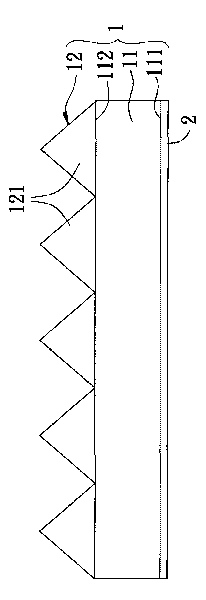

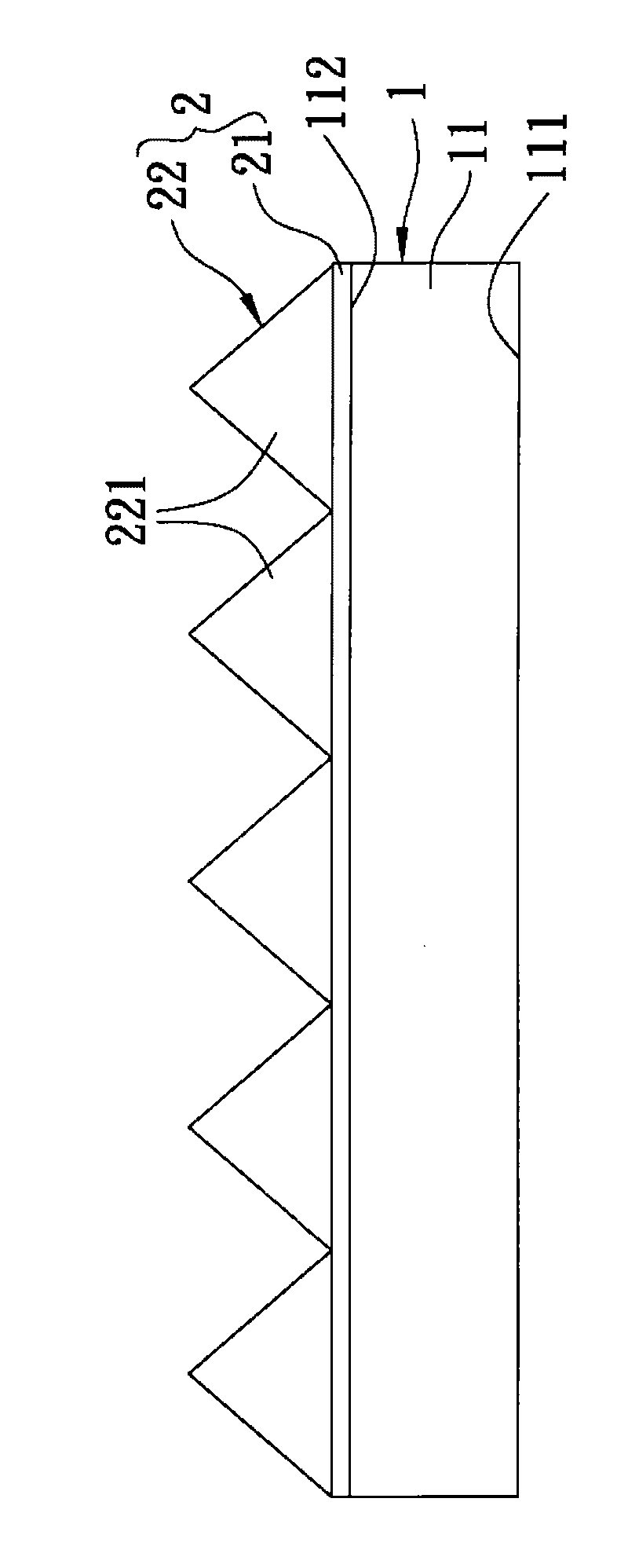

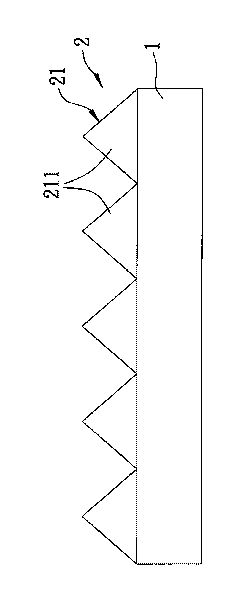

[0020] refer to figure 1 , the first preferred embodiment of the antistatic optical film of the present invention comprises: a substrate 1 , and an antistatic layer 2 disposed on the surface of the substrate 1 .

[0021] The substrate 1 includes a substrate part 11 and a light collecting part 12 disposed on the surface of the substrate part 11 . The thickness of the substrate portion 11 is about 125 μm, and has a first surface 111 and a second surface 112 spaced apart in opposite directions. The substrate 1 selected by the present invention has no other special restrictions except that it needs to have light transmittance, and its material is such as the following resins: polyethylene terephthalate (polyethylene terephthalate, PET), polycarbonate (p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap