Control system for multi-axis servo motor

A servo motor and control system technology, applied in the field of control, can solve problems such as inability to synchronize, and achieve the effects of minimized size, fast performance, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

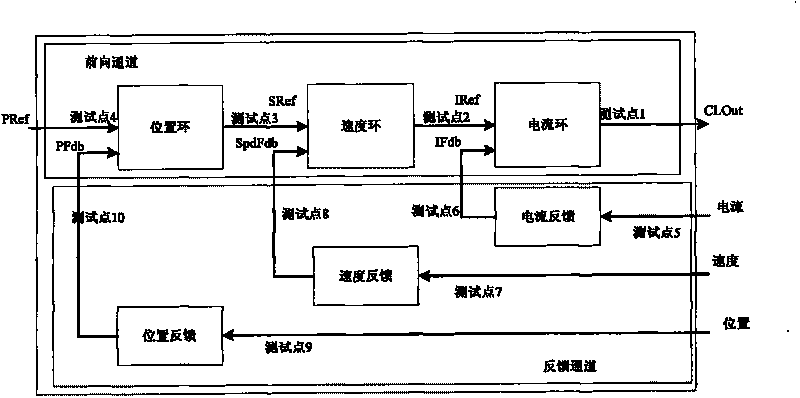

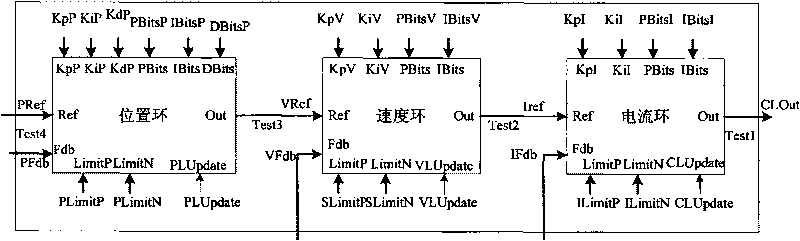

[0045] Such as figure 1 As shown, the system model consists of two parts: the forward channel and the feedback channel. The model description of the forward channel is as follows figure 2 shown. figure 2The port description of the model shown is

[0046] model

[0047] Input[11:0]PRef;

[0048] Input[14:0]IFdb;

[0049] Input[14:0] VFdb;

[0050] Input[11:0]PFdb;

[0051] Output[15:0]CLOut;

[0052] Figure 1-2 KpP, KiP, KdP, PbitsP, IbitsP, DbitsP, PlimitP, PlimitN, KpV, KiV, PbitsV, IbitsV, VlimitP, VlimitN, KpI, KiI, PbitsI, IbitsI, IlimitP, and ILimitN are parameters that can be set. CLUpdate, VLUpdate, PLUpdate are used to control the calculation of current loop, speed loop and position loop respectively.

[0053] Can be figure 2 described in language

[0054] If PLUpdate then

[0055] Do 'PositionLoop';

[0056] Do 'VelocityLoop';

[0057] Do 'CurrentLoop';

[0058] Else if VLUpdate then

[0059] Do 'VelocityLoop';

[0060] Do 'CurrentLoop';

[0061...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com