Simulation training system of 10KV typical customer distribution room

A customer and room imitation technology, applied in teaching models, educational tools, instruments, etc., can solve problems such as inability to deeply understand equipment performance indicators, technical parameter coordination and interrelationship, lack of practical hands-on ability, insecurity, etc., and achieve post comprehensiveness The effect of improving business level and on-site actual operation level and improving the ability to deal with emergencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below through specific implementations.

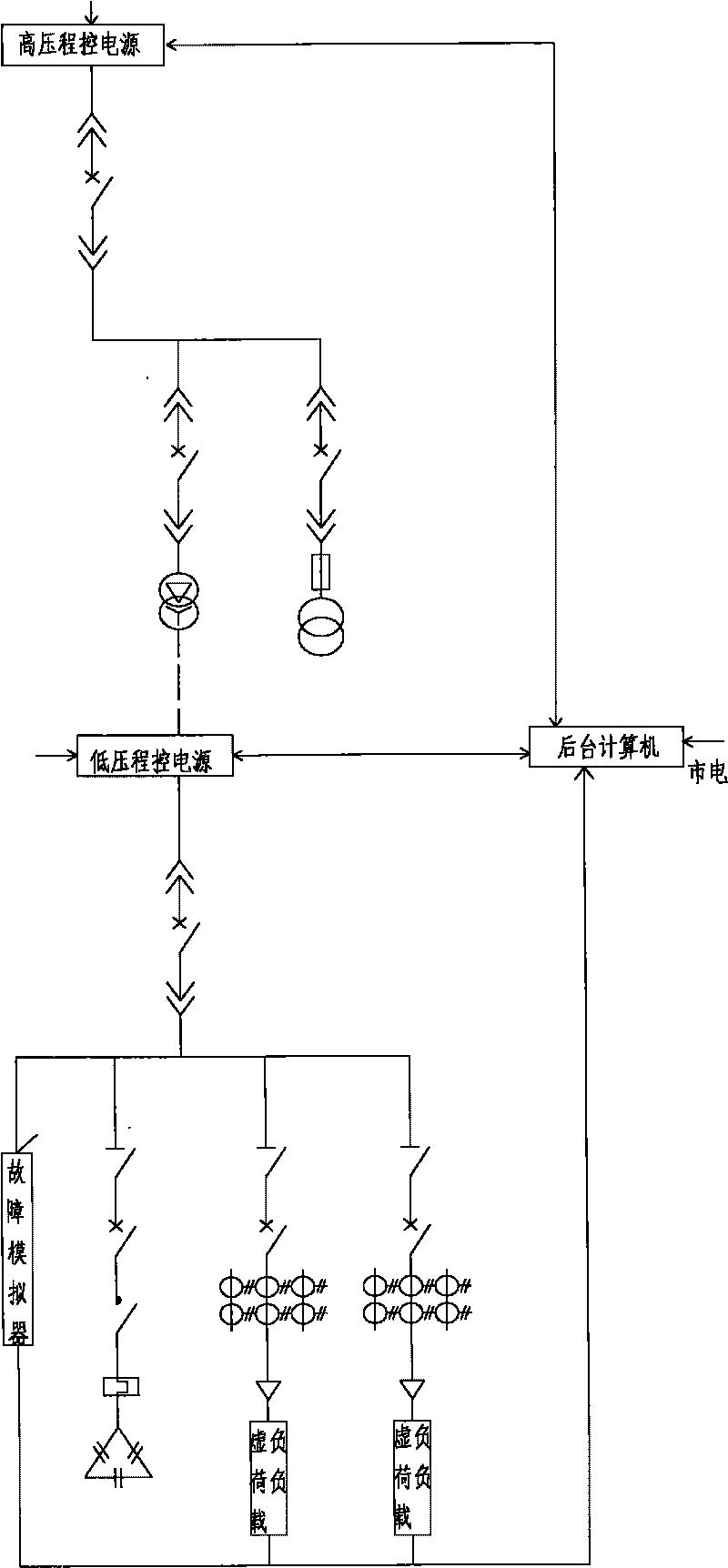

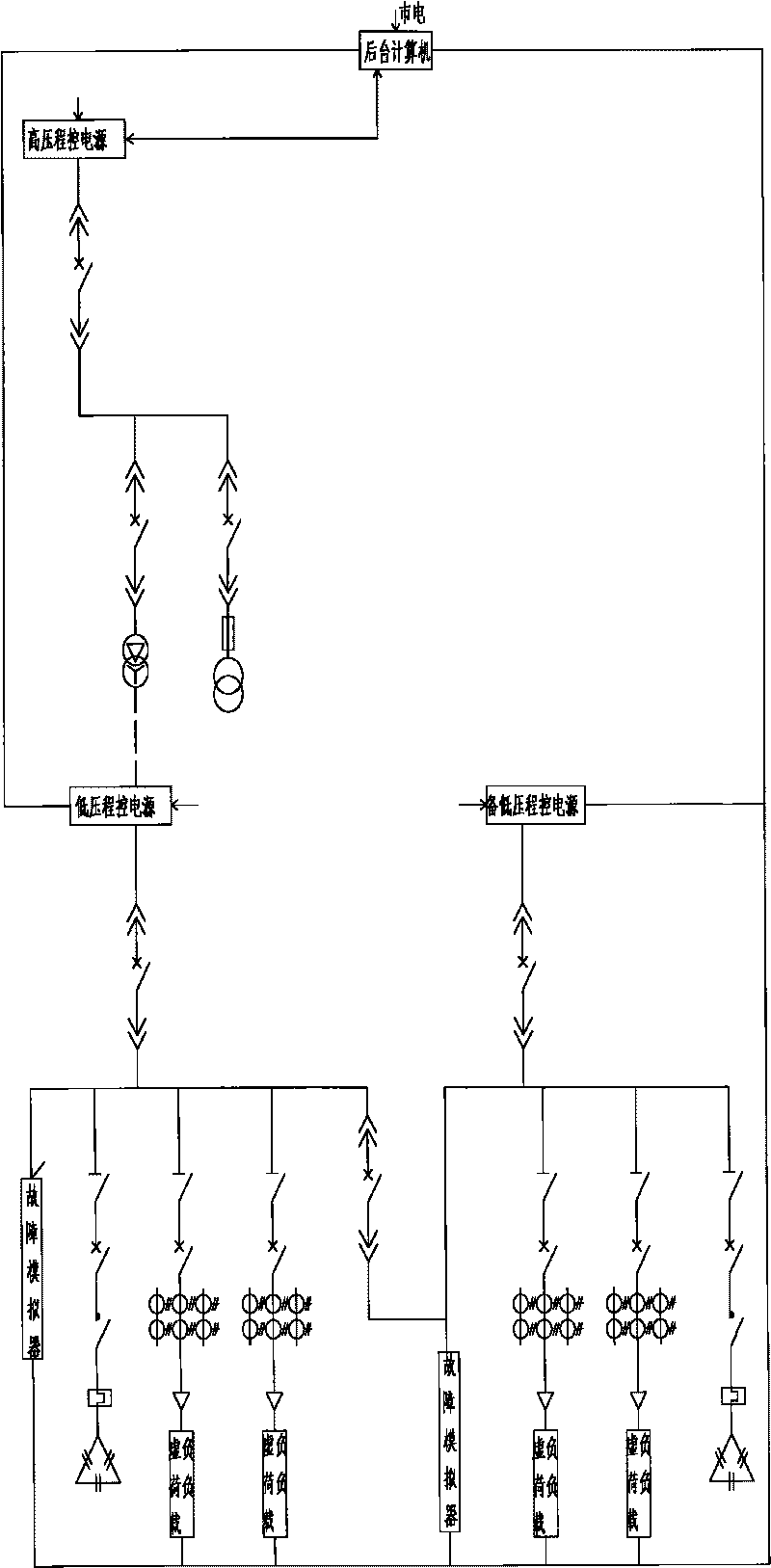

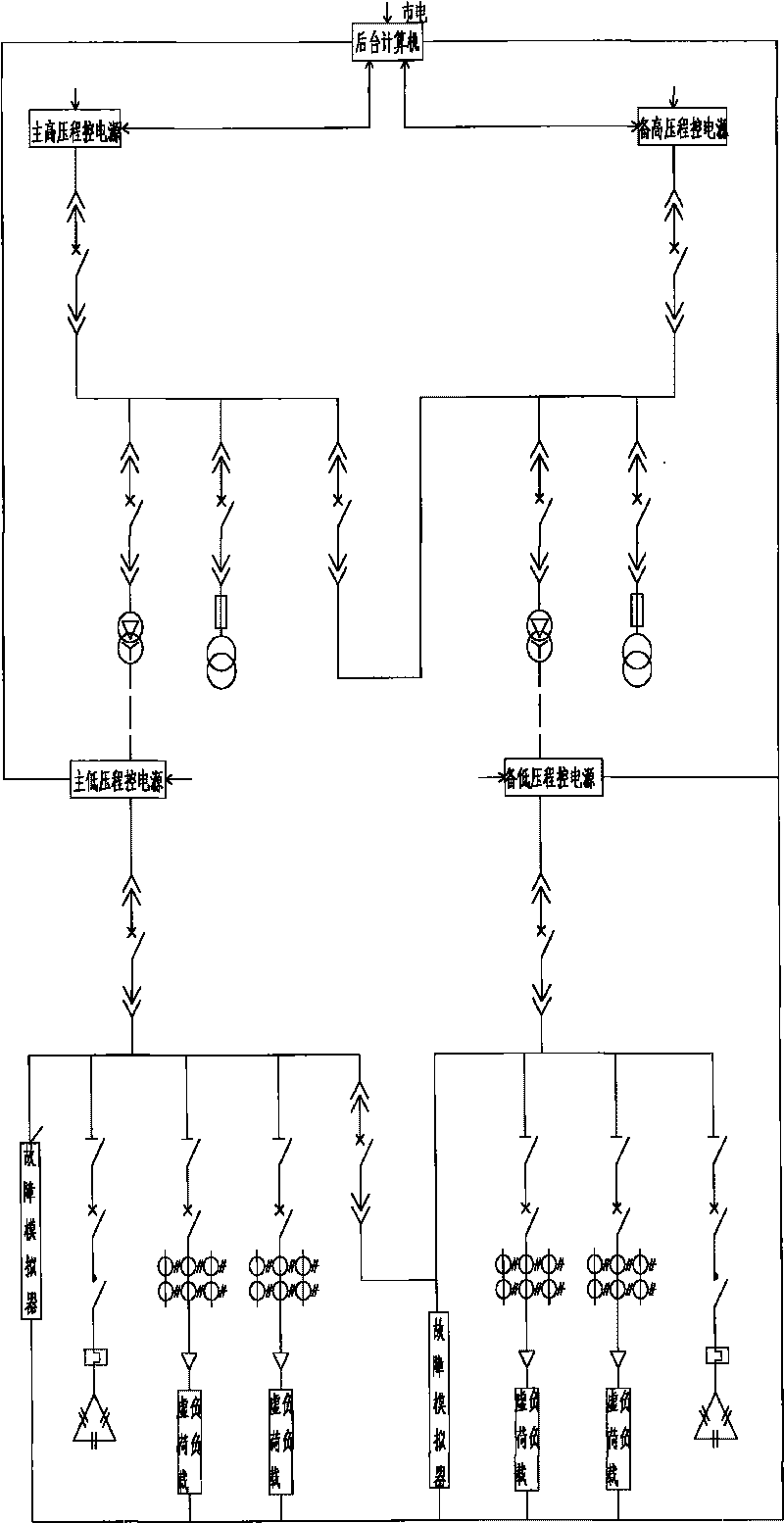

[0027] Such as figure 1 Shown is a schematic structural diagram of a 10KV typical customer power distribution room simulation training system of the present invention. The system includes a background computer, a high-voltage unit and a low-voltage unit. The high-voltage unit includes a high-voltage program-controlled power supply, a high-voltage outlet cabinet and a transformer cabinet connected to it. And PT cabinet, the low-voltage unit includes low-voltage program-controlled power supply, low-voltage outgoing cabinet, reactive power compensation cabinet and power distribution cabinet connected to it, as well as fault simulator circuit and dummy load circuit corresponding to each power distribution cabinet; the above-mentioned high-voltage program control The three-phase voltage output of the power supply is correspondingly connected to the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com