Semiconductor solenoid inductor and manufacture method thereof

A manufacturing method and solenoid technology, applied in the field of inductance, can solve the problems of occupation, large chip area, inability to generate large magnetic induction intensity, etc., and achieve the effects of reducing chip area, improving integration, and improving magnetic induction intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

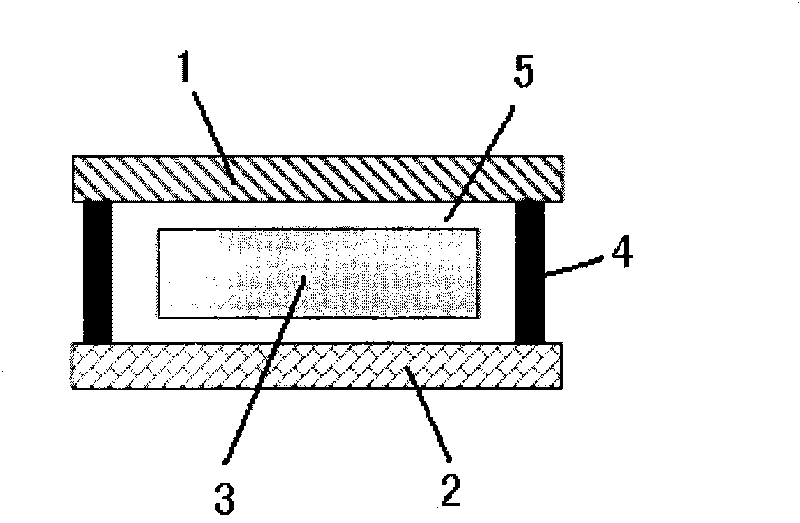

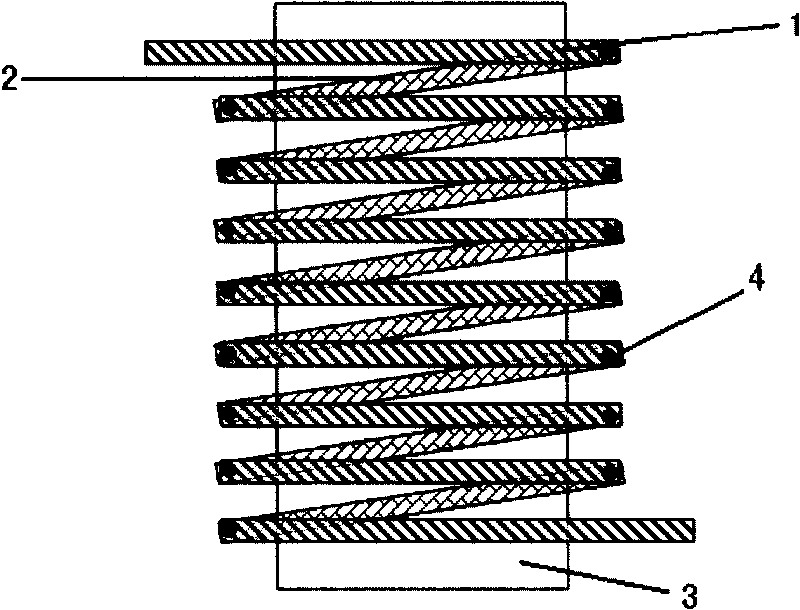

[0019] The invention discloses a semiconductor solenoid inductor, such as figure 2 , image 3 and Figure 4 As shown, it includes multiple upper metal strips 1 and multiple lower metal strips 2, a magnetic core 3 is sandwiched between the upper metal strip 1 and the lower metal strip 2, the upper metal strip 1 and the lower metal strip 2 The strips 2 are connected end to end in sequence through the contact holes 4 to form a solenoid that surrounds the magnetic core 3 in the same direction, and the magnetic core 3 is surrounded by an insulating medium 5 .

[0020] like image 3 As shown, the magnetic core is strip-shaped.

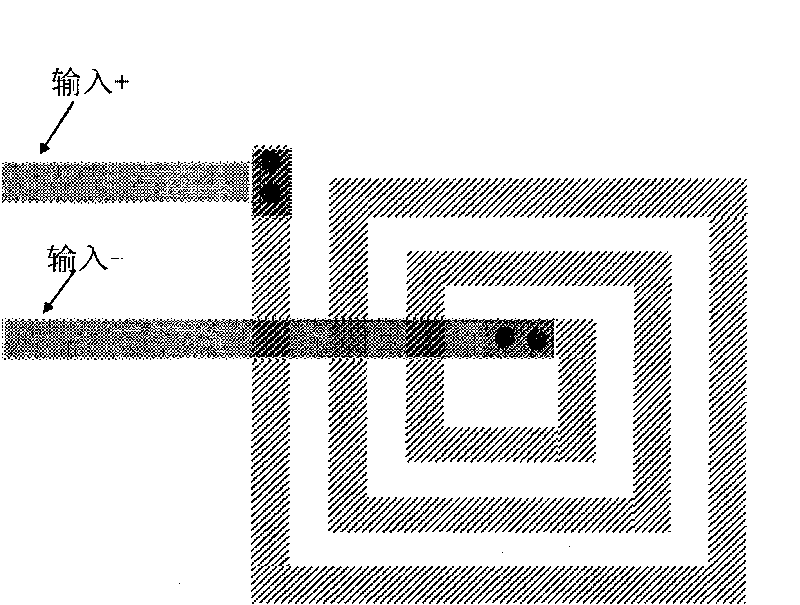

[0021] like Figure 4 As shown, the magnetic core is annular.

[0022] The invention also discloses a manufacturing method of the above-mentioned semiconductor solenoid inductor, which comprises the following steps in sequence:

[0023] (1) Photolithography and etching to form lower metal strips 2, such as Figure 5 shown;

[0024] (2) An insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com