Quad flat no-lead encapsulation structure and encapsulation method thereof

A technology of leadless packaging and packaging method, which is applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the degradation of pin insulation performance, the deterioration of conductive pin insulation properties, and limit the application of QFN packaging technology. field and other issues, to achieve the effect of improving insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

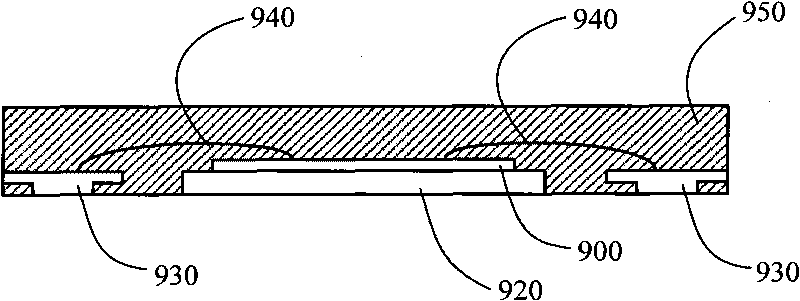

[0019] The specific implementation of a quadrilateral flat no-lead package structure and its packaging method provided by the present invention will be described in detail below with reference to the accompanying drawings.

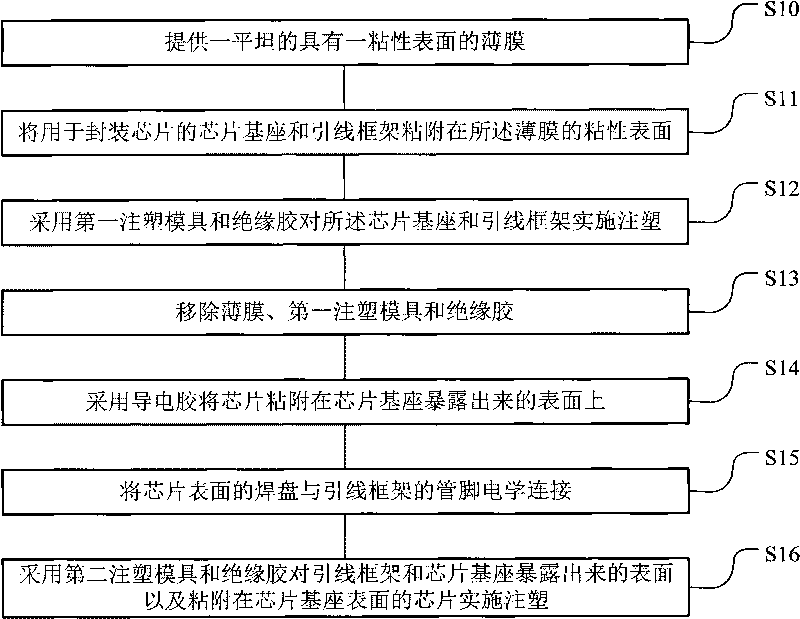

[0020] attached figure 2 In the shown specific embodiment of the present invention, the schematic diagram of the implementation steps of the packaging method includes the following steps: step S10, providing a flat film with an adhesive surface; step S11, using the chip base and the lead frame for packaging the chip Adhering to the sticky surface of the film; Step S12, using the first injection mold and insulating glue to inject the chip base and lead frame; Step S13, removing the film, the first injection mold and insulating glue; Step S14 , using conductive glue to adhere the chip on the exposed surface of the chip base; step S15, electrically connecting the pads on the chip surface with the pins of the lead frame; step S16, using the second injection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com