Soft magnetic metal powder with negative thermal expansion coefficient and high insulation property and preparation method thereof

A technology of negative thermal expansion coefficient and soft magnetic metal, which is applied in metal processing equipment, inductance/transformer/magnet manufacturing, inorganic material magnetism, etc., can solve problems such as poor insulation properties, product cracking, and easy expansion when heated, so as to improve insulation properties , reduce thermal expansion problem, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

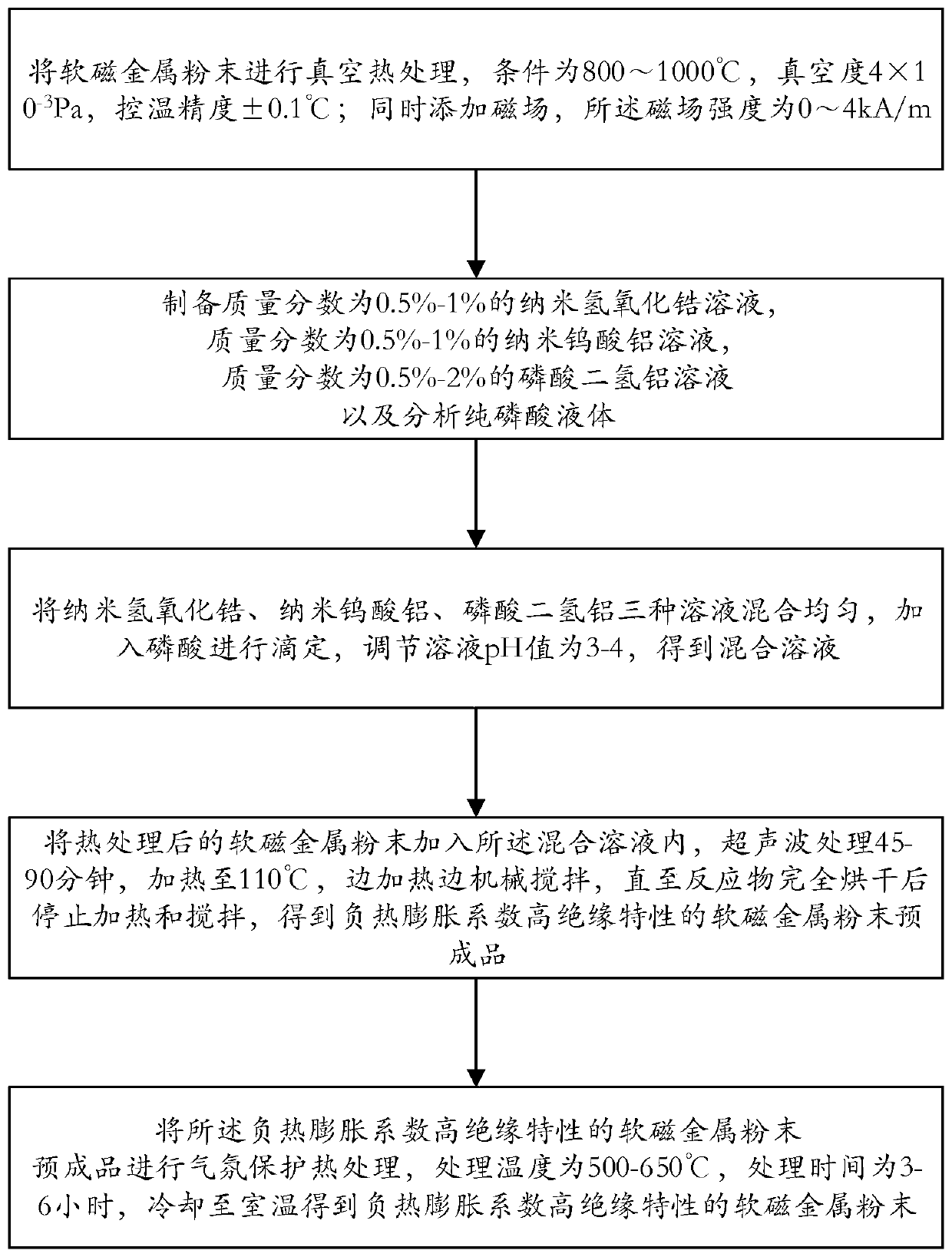

[0026] Please refer to figure 1 , figure 1 It shows a schematic flow chart of the present invention for preparing soft magnetic metal powder with negative thermal expansion coefficient and high insulation properties. Such as figure 1 As shown, the preparation method of the soft magnetic metal powder with negative thermal expansion coefficient and high insulating properties comprises the following steps:

[0027] The soft magnetic metal powder is subjected to vacuum heat treatment, wherein the conditions of the heat treatment are 800-1000°C, and the degree of vacuum is 4×10 -3 Pa, the temperature control accuracy is ±0.1°C; a magnetic field is added while heat-treating the soft magnetic metal powder, and the magnetic field strength is 0-4kA / m.

[0028] Preparation of nano-zirconium hydroxide solution with a mass fraction of 0.5%-1%, nano-aluminum tungstate solution with a mass fraction of 0.5%-1%, aluminum dihydrogen phosphate solution with a mass fraction of 0.5%-2%, and an...

Embodiment 1

[0036] Carry out vacuum heat treatment with 2500g carbonyl iron powder, the condition of described heat treatment is 800 ℃, vacuum degree 4×10 - 3 Pa, temperature control accuracy ±0.1°C, adding a magnetic field while heat-treating the soft magnetic metal powder, the magnetic field strength is 3kA / m;

[0037] Prepare 500 g of nano-zirconium hydroxide ethanol solution with a mass fraction of 0.5%, 500 g of nano-aluminum tungstate ethanol solution with a mass fraction of 0.6%, 500 g of distilled aqueous solution of aluminum dihydrogen phosphate with a mass fraction of 0.5%, and 100 g of analytically pure phosphoric acid liquid;

[0038] Mix 400g of nano-zirconium hydroxide, 200g of nano-aluminum tungstate, and 100g of aluminum dihydrogen phosphate evenly, add phosphoric acid for titration, adjust the pH value of the solution to 3, and obtain a mixed solution;

[0039] Add the heat-treated carbonyl iron powder into the mixed solution, ultrasonically treat for 90 minutes, heat to...

Embodiment 2

[0051] Carry out vacuum heat treatment with 8000g FeSiCr alloy powder, the condition of described heat treatment is 1000 ℃, vacuum degree 4×10 -3 Pa, temperature control accuracy ±0.1°C, adding a magnetic field while heat-treating the soft magnetic metal powder, the magnetic field strength is 4kA / m;

[0052] Prepare 1000 g of nano-zirconium hydroxide ethanol solution with a mass fraction of 0.8%, 1000 g of nano-aluminum tungstate ethanol solution with a mass fraction of 1%, 500 g of distilled aqueous solution of aluminum dihydrogen phosphate with a mass fraction of 2%, and 100 g of analytically pure phosphoric acid liquid;

[0053] Mix the three solutions of 500g nanometer zirconium hydroxide, 800g nanometer aluminum tungstate, and 500g aluminum dihydrogen phosphate evenly, add phosphoric acid for titration, adjust the pH value of the solution to 3, and obtain a mixed solution;

[0054] Add the heat-treated iron-silicon-chromium alloy powder into the mixed solution, ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com