Method for forming interconnection line in semiconductor device

A technology of interconnection wires and semiconductors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of huge investment in research and development costs, and achieve the effect of reducing the generation of holes and reducing the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0031] As a first embodiment of the present invention, the step of forming interconnection lines in a semiconductor device includes:

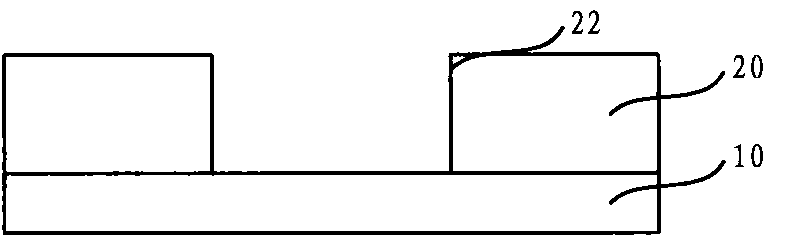

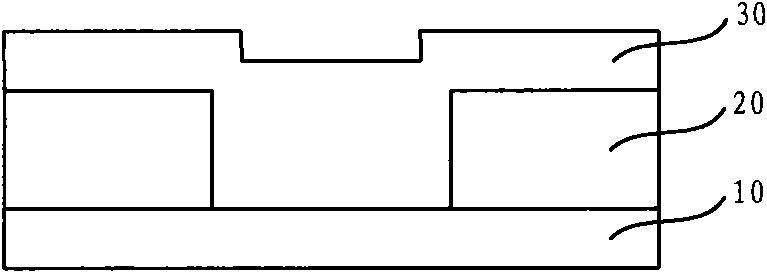

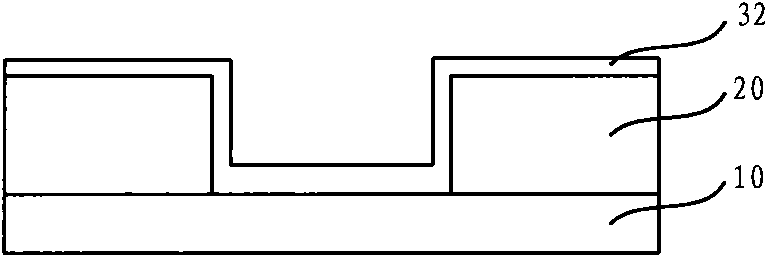

[0032] First, like Figure 7 As shown, a dielectric layer 120 having an interconnect structure 122 and a seed layer (not shown) covering the bottom and sidewalls of the interconnect structure 122 are formed on the substrate 100;

[0033] After defining the active region of the device on the substrate and completing the shallow trench isolation, and then forming the gate structure and the source and drain regions, the base 100 is formed. In addition, after defining the active area of the device on the substrate and completing the shallow trench isolation, and then forming the gate structure and the source and drain regions, the first interlayer dielectric layer (ie, the pre-metal dielectric layer, PMD) is then deposited, and continue After the first layer interconnection line is formed in the first interlayer dielectric layer, the substrate 100 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com