SONOS flash memory unit and manufacturing method thereof

A technology of flash memory unit and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as increasing process complexity, reduce short-channel effect, and increase effective channel length , The effect of improving programming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

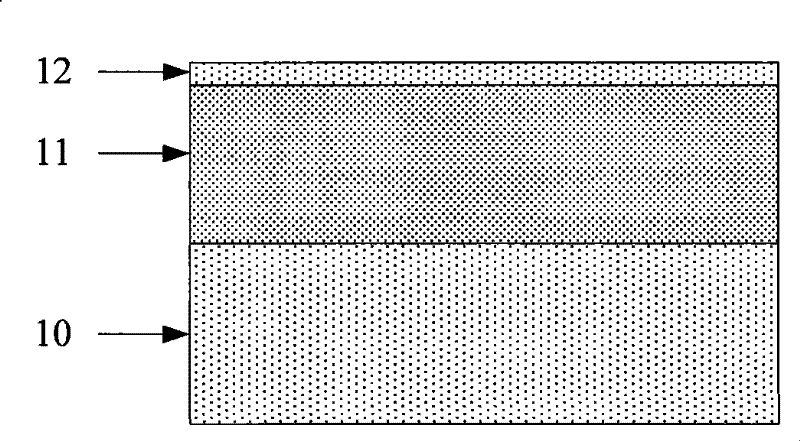

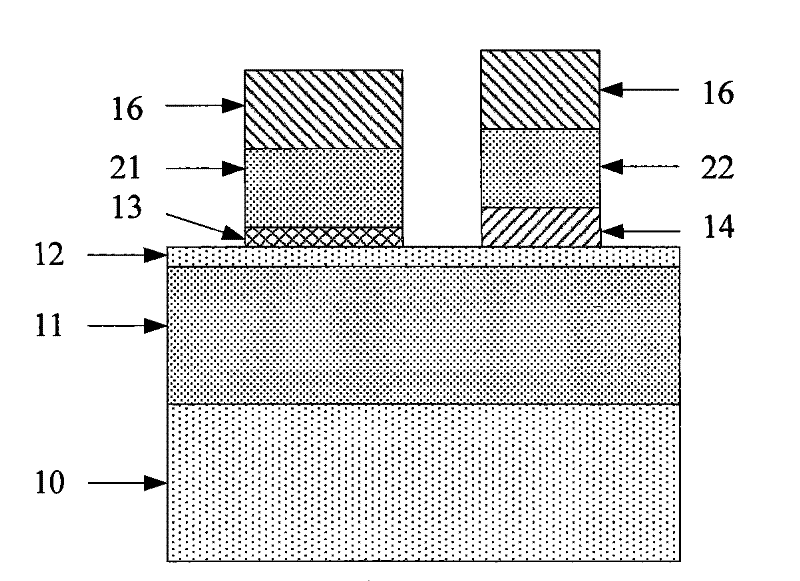

[0032] Step 1, see Figure 1a N-type impurities are implanted on the P-type silicon substrate 10 by an ion implantation process to form an N-well 11. Commonly used N-type impurities include phosphorus, arsenic, and antimony. Next, P type impurities are implanted on the N well 11 by an ion implantation process to form a P type buried trench 12. Commonly used P-type impurities include boron and so on.

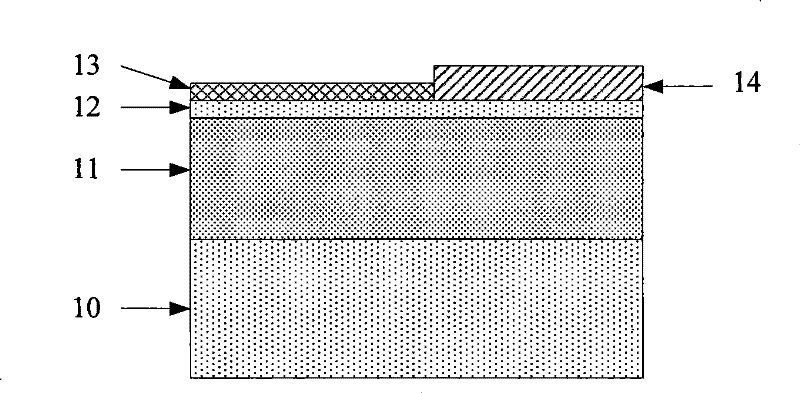

[0033] Step 2, see Figure 1b A layer of ONO (silicon oxide / silicon nitride / silicon oxide) dielectric 13 and a layer of silicon oxide 14 are deposited on the surface of the silicon wafer, which are respectively used for the gate dielectric layer and the gate oxide layer of the SONOS device. The ONO dielectric 13 and the silicon oxide 14 are arranged horizontally instead of vertically.

[0034] For example, a layer of silicon oxide 14 can be completely deposited on the surface of the silicon wafer, and then photoresist can be applied. After exposure and development, the etching windo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com