Rail type sector ash scrapper used for cylindrical horizontal electro-precipitator

An electrostatic precipitator and horizontal type technology, which is applied in the field of orbital fan-shaped dust scraping devices for cylindrical horizontal electrostatic precipitators, can solve the problems of the platform being easily stressed, deformed and unstable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

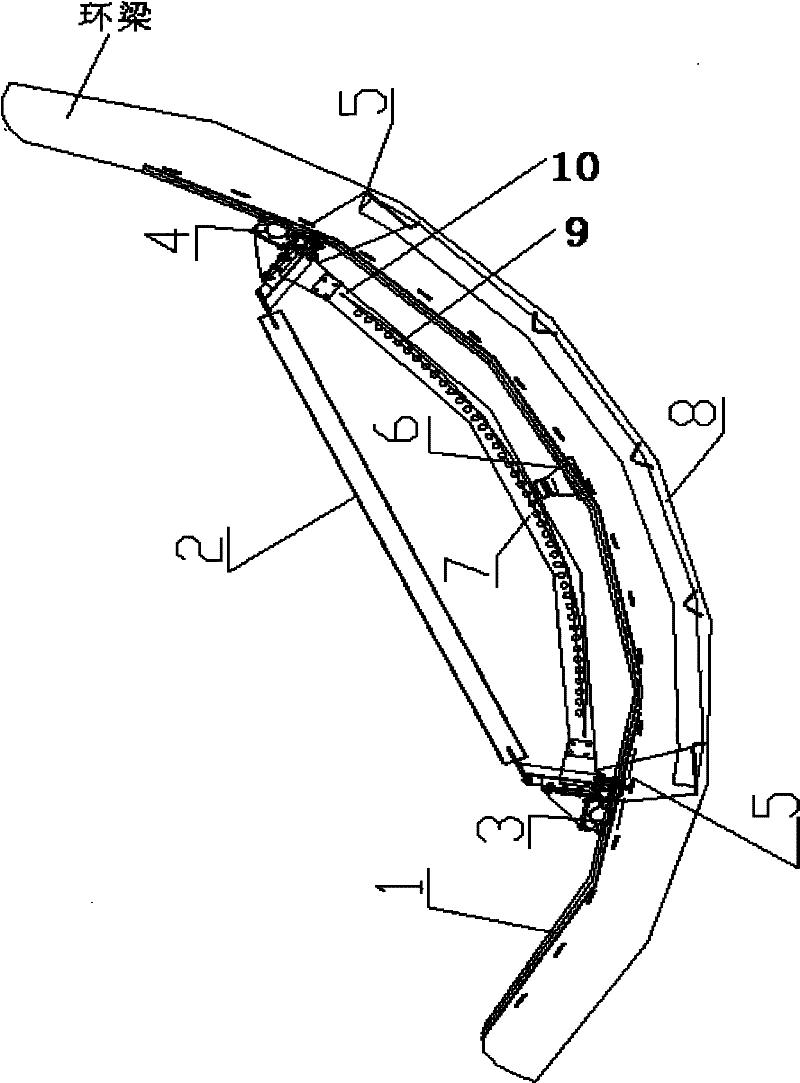

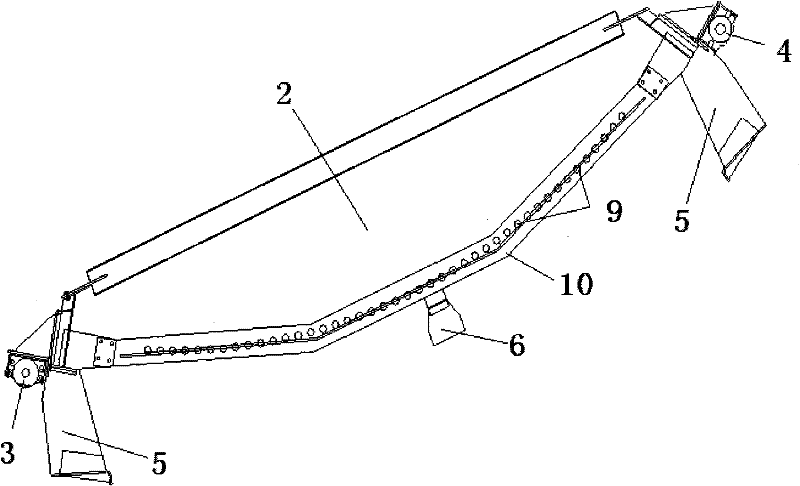

[0010] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

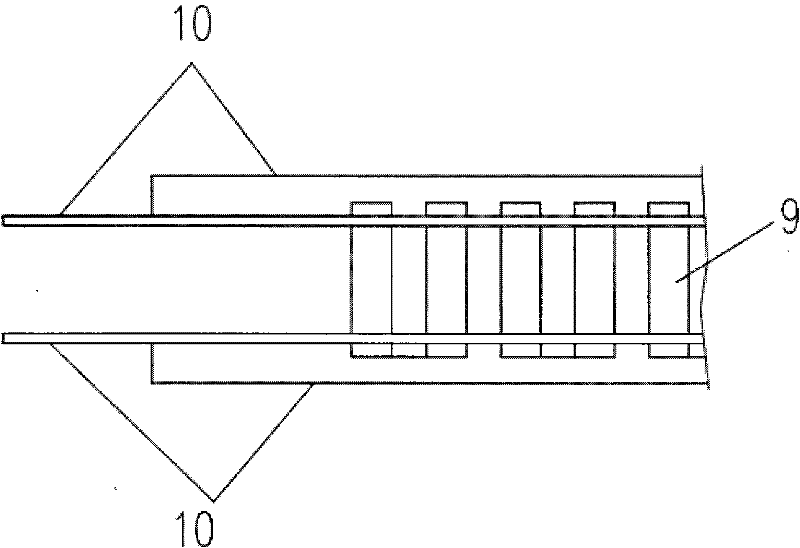

[0011] refer to figure 1 , figure 2 , image 3 , a track-type fan-shaped dust scraping device for a cylindrical horizontal electrostatic precipitator, including an arc-shaped rail 1 fixed on the ring beam, the arc length of the arc-shaped rail is determined by the specific ash scraping angle, because the cylindrical The cylinder diameter of the horizontal electrostatic precipitator is different, and one or two curved steel rails can be designed, and a certain gap is left between the two; the two ends of the fan-shaped support 2 are respectively equipped with a guide roller 3 and a movable roller 4, which guide The roller 3 and the movable roller 4 are rollingly connected with the rail 1. The ring gear 7 includes cylindrical pins 9 arranged in parallel. The two ends of all the cylindrical pins 9 are fixed by two fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com