Variable pressure hydraulic spacing adjusting device

A distance-adjusting device and variable-pressure technology, which is applied in the field of distance-adjusting devices, can solve the problems of affecting work continuity, high work intensity, and difficulty in precise positioning of the roll distance, so as to improve the roll distance control accuracy and safety protection pressure accuracy, The effect of improving efficiency and product quality, ensuring work continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

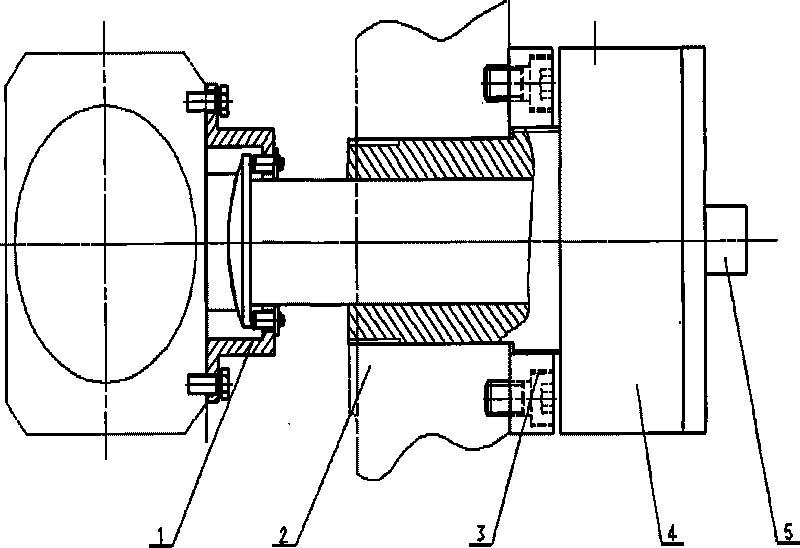

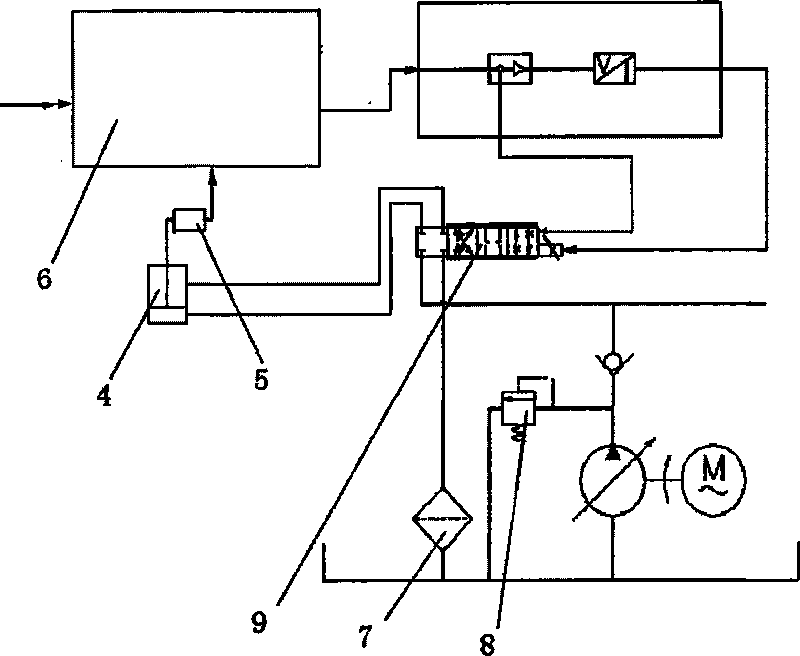

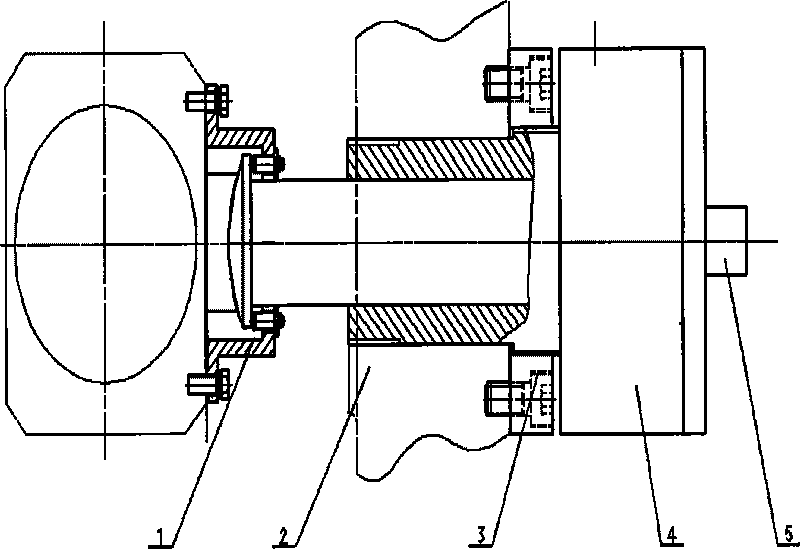

[0027] Such as figure 1 and figure 2 As shown, the variable pressure hydraulic distance adjustment device includes a connecting sleeve 1, a frame 2, a connecting plate 3, a hydraulic cylinder 4, a displacement sensor 5, a PID controller 6, an electronically controlled proportional reversing valve 9, and a piezoelectrically controlled proportional reversing valve. The valve 9, the pressure relief valve 8 and the oil filter 7 together form the hydraulic distance control system of the variable pressure hydraulic distance control device. figure 2 As can be seen in the schematic diagram of the hydraulic distance control system, through the control of the electronically controlled proportional reversing valve 9, the system can realize the following actions: hydraulic cylinder piston rod fast forward, fast back, slow forward, slow back, pressure holding static , the synchronous action of the two hydraulic cylinders 4 is realized through the proportional control of the proportional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com