Anti-leakage sealing bottleneck structure for canned water

A technology for anti-leakage and sealing bottles, which is applied in the field of barreled water bottle sleeves, bottle mouths for bottled water, and anti-leakage sealing bottle mouth structures for bottled water. Receiving orders and other issues to achieve the effect of reducing weight and volume, reducing consumption and loss, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

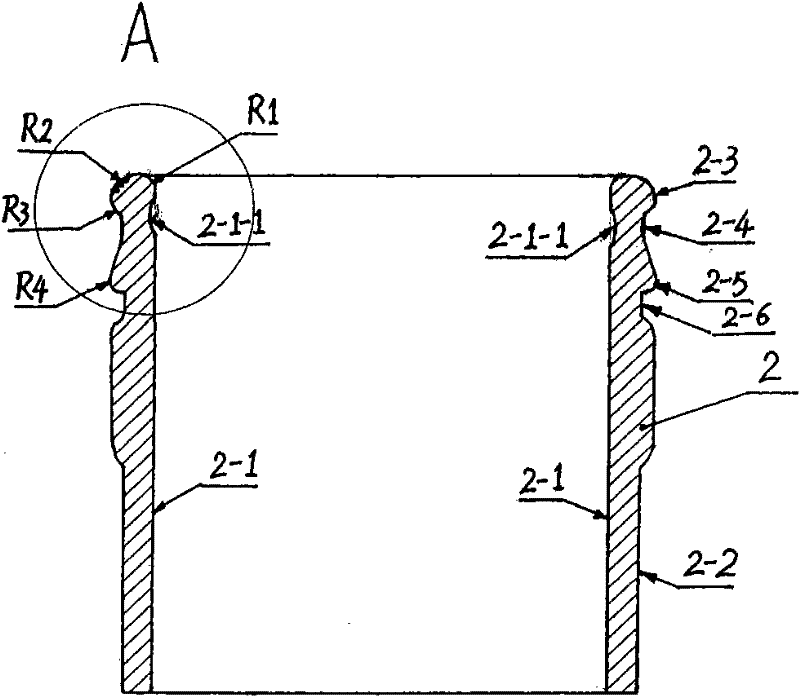

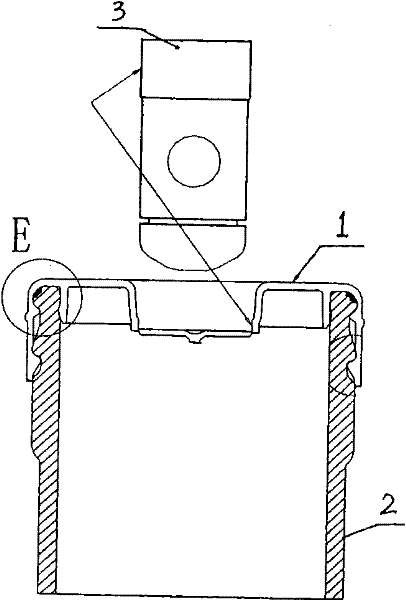

[0024] figure 1 and figure 2 Constitute the specific embodiment 1 of the present invention.

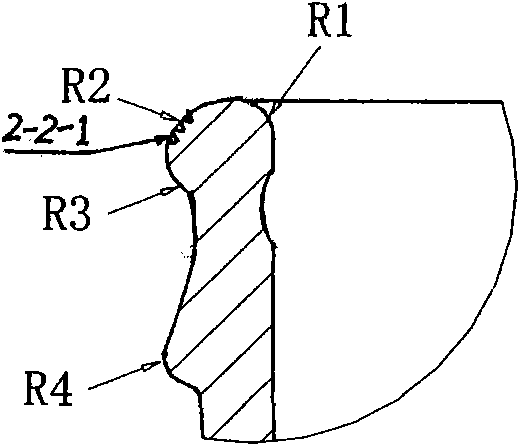

[0025] refer to figure 1 and figure 2 , this embodiment includes a bottle mouth 2, an arc-shaped concave ring 2-1-1 is arranged on the upper or middle part of the inner wall 2-1 of the bottle mouth 2, and the joint between the inner wall 2-1 of the bottle mouth 2 and the top is R Arc-shaped ring R1, the joint between the outer wall 2-2 of the bottle mouth 2 and the top is an R arc-shaped ring R2, and an R arc-shaped ring R3 is arranged on the upper or middle part of the outer wall 2-2 of the bottle mouth 2, and the R arc-shaped ring R1 An R arc-shaped convex ring 2-3 is formed between the R arc-shaped ring R3, and a concave ring 2-4 is arranged under the R arc-shaped ring R3.

[0026] In this embodiment, a lower R arc-shaped convex ring 2-5 is provided under the concave ring 2-4 on the outer wall of the bottle mouth 2. A concave ring 2-6 is arranged under the R arc-shaped conve...

specific Embodiment 2

[0031] The characteristics of other specific embodiments of the present invention are: the lower R arc-shaped convex ring 2-5 is omitted, or the concave ring 2-6 is omitted, and the rest are the same as the specific embodiment 1.

specific Embodiment 3

[0032] The characteristics of other specific embodiments of the present invention are: omit the three locking dimples 2-2-1 located at the R arc-shaped ring R2, or change the number of the locking dimples 2-2-1 to one or two One, four or five, all the other are identical with specific embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com