Low-powered pontoon type decanting method and device

A buoy-type, low-power technology, applied in the field of water treatment, can solve problems such as complex control methods and large power consumption, and achieve the effects of precise control, stable operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

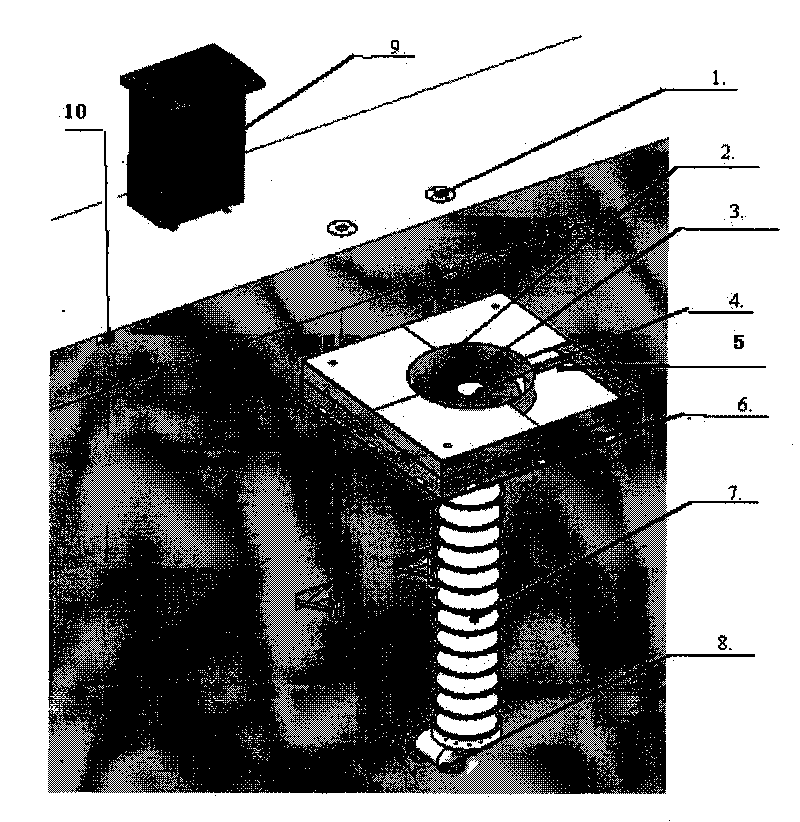

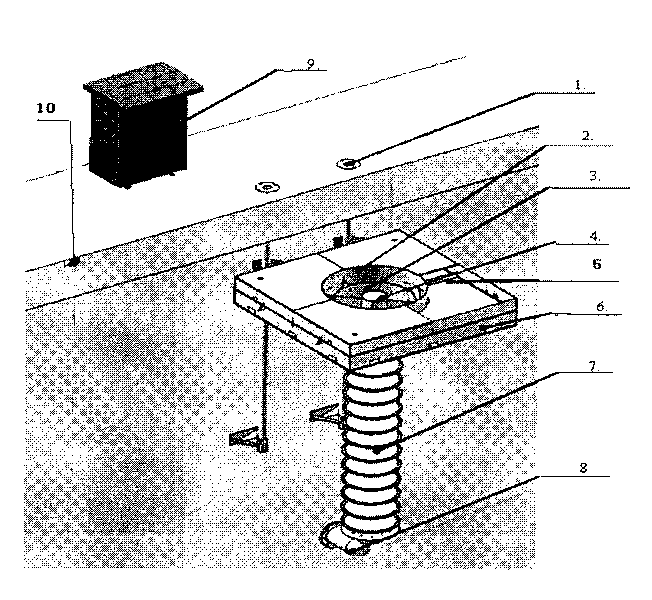

[0034] according to figure 1 The preferred embodiment of the low power buoy type decanter, the utility model consists of a guide rod (1), a slag retaining plate (2), a decanting weir (3), a liquid level switch 1 (4), a fixed buoy box (5) , air injection buoyancy tank (6), drain main pipe (7), drain elbow (8), electrical control box (9), liquid level switch 2 (10) and other parts; guide rod (1) and liquid level switch 2 (10) One side of the sewage tank is fixed, the guide rod (1) is connected with the fixed buoyancy box (5) and the air injection buoyancy box (6), the air injection buoyancy box (6) is fixed on the lower end of the fixed buoyancy box (5), and the The slag weir plate (2) is connected with the decanting weir (3), and the slag retaining weir plate (2) and the decanting weir (3) are fixed in the fixed buoyancy tank (5) and the air injection buoyancy tank (6). The switch 1 (4) is fixed on the decanting weir (3), the lower end of the decanting weir (3) is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com