High-temperature cable direct reading five-parameter logging instrument

A logging tool, high temperature technology, applied in the direction of measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problems of real-time monitoring, economic loss, damage to logging tools and cables, etc., to reduce operating time and operation cost, reduce economic loss, and reduce the effect of construction intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

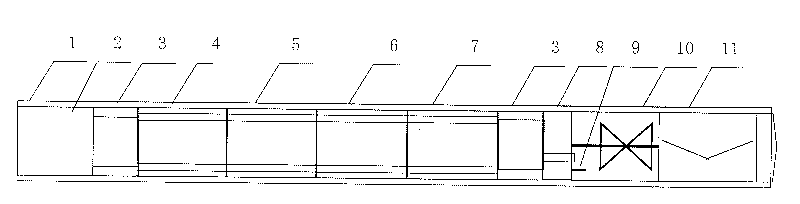

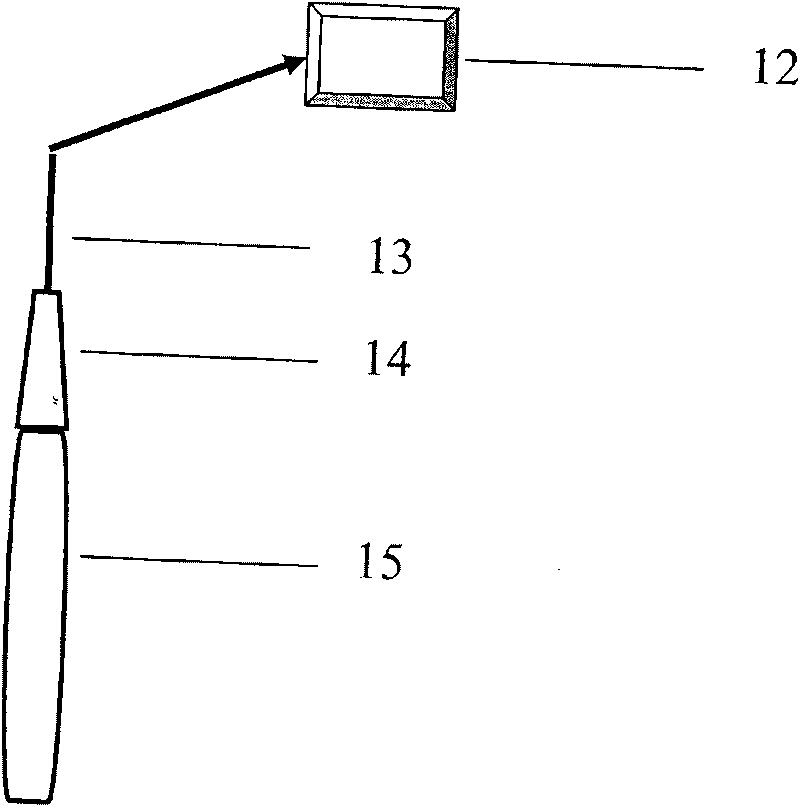

[0012] exist figure 1 Medium and high temperature cable direct-reading five-number logging tool consists of logging tool shell 1, logging tool upper connector 2, heat absorber 3, natural gamma circuit 4, road data acquisition circuit 5, magnetic positioning circuit 6, pressure sensor 7. Thermal resistance diversion section 8, temperature sensor 9, flow sensor 10, and centralizer 11; the electronic components and pressure sensors of the high-temperature cable direct-reading five-parameter logging instrument are made of military high-temperature-resistant devices, and placed in high-temperature metal insulation Inside the shell 1; the natural gamma ray circuit 4 inside the high-temperature cable direct reading five-parameter logging tool, the road data acquisition circuit 5, the magnetic positioning circuit 6, and the pressure sensor 7 are connected by circuits to collect natural gamma ray, magnetic positioning, pressure, temperature, For the data of the flow rate, at the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com