Manufacturing method of insulation bearing shell of oil well logging instrument

A manufacturing method and oil logging technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well parts, etc., can solve the problems of inconvenient production and application maintenance, complex process, easy oil leakage, etc. The effect of unique molding process and precise control of glue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

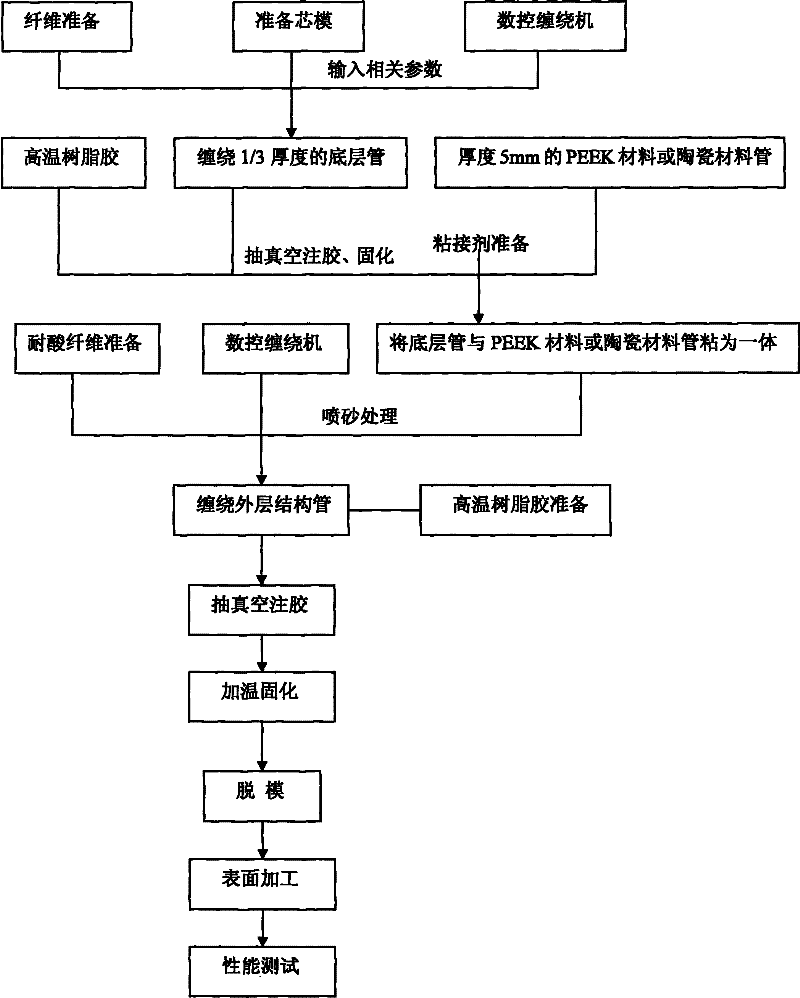

Method used

Image

Examples

Embodiment Construction

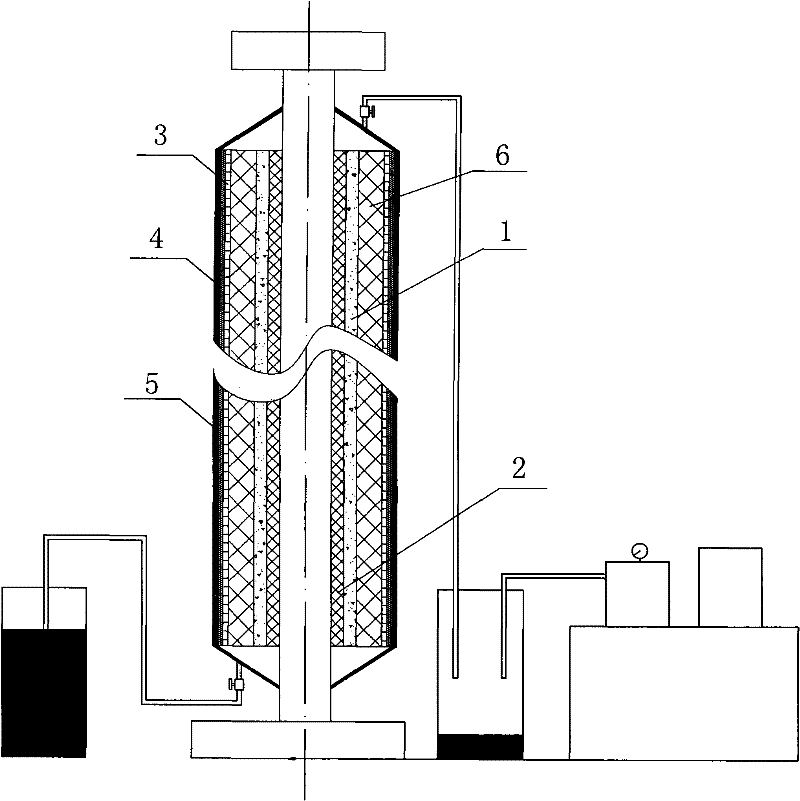

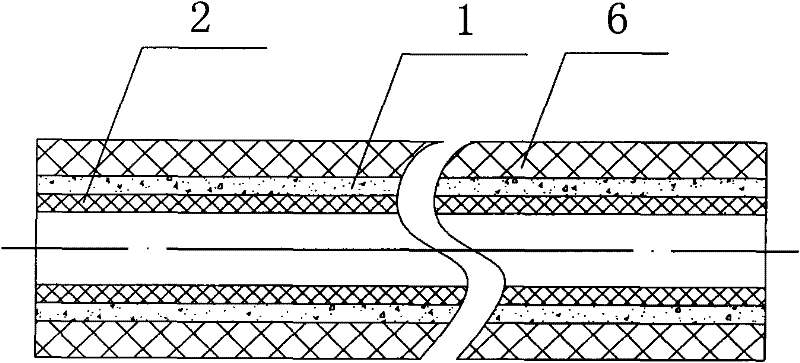

[0017] The present invention develops a new type of pressure-insulating electrode that is not filled with oil, an absolute pressure-bearing shell, through the innovation of composite insulating materials. The structure of this electrode system can be widely used in induction logging, electromagnetic wave logging, formation dip logging, and other insulating shells that need to withstand downhole mud pressure, so as to simplify the instrument structure and reduce the length of the instrument (the pressure balance can be removed short section), for the purpose of reducing manufacturing costs.

[0018] Because the geological environment several kilometers underground is very complicated. The rock on the borehole wall is hard, so the wear resistance of the absolute pressure-bearing shell is very important in the process of lifting the logging instrument. At three or four kilometers downhole, the temperature is 175°C and the pressure is above 140MPa, accompanied by crude oil, natur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com