Biosynthetic base oil, biosynthesis based environmentally-friendly drilling fluid for shale gas drilling, and preparation methods and application of biosynthetic base oil and biosynthesis based environmentally-friendly drilling fluid

A biosynthesis, base oil technology, applied in wellbore/well components, chemical instruments and methods, earth-moving drilling, etc., can solve the problem that the temperature resistance, inhibition and lubricity of high-performance water-based drilling fluid are difficult to meet on-site construction. requirements, drilling cuttings are difficult to handle, and the stability is not strong, so as to achieve good oxidation stability, improve ROP, and improve drilling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation process of emulsifier A is as follows: lauryl alcohol first undergoes a substitution reaction with ethylene oxide, the reaction molar ratio is 1-3:1, and the reaction conditions are: react at 100°C-150°C for 2-5 hours. The reaction product is further polymerized into an ether, and after adding 10 to 15 ethers, the emulsifier A is obtained. The prepared emulsifier A showed better emulsifying ability, wetting ability and biodegradability. Lauryl alcohol in the above-mentioned preparation process also can be replaced by oleyl alcohol, cyclohexanol, stearyl alcohol. The preparation process of emulsifier B is as follows: the three raw materials of iron sulfonate, sodium alkylbenzene sulfonate and sodium alkyl succinate sulfonate are mixed at a high speed at 60°C in a weight ratio of 2:1:1. That is, emulsifier B is obtained, and the prepared emulsifier B is a good oil-soluble emulsifier and dispersant. Emulsifier C is zinc stearate, which has good thermal st...

Embodiment 2

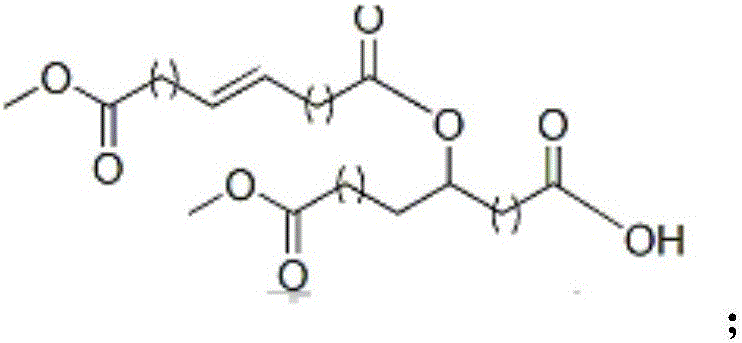

[0057] A preparation method of biosynthetic base oil, comprising the steps of:

[0058] 1. The waste vegetable oil is used to obtain the semi-finished product of unsaturated fatty acid methyl ester by using the existing process: the waste vegetable oil and absolute ethanol are subjected to esterification reaction, and then neutralized with acid, and the product is distilled to obtain the semi-finished product of unsaturated fatty acid methyl ester ;

[0059] 2. Weigh 500 g of unsaturated fatty acid methyl ester and add it to the high-pressure reaction device.

[0060] 3. Add 9 g of concentrated sulfuric acid with a concentration of 65% as a catalyst in the high-pressure reaction device.

[0061] 4. Carry out self-lactonization reaction, the reaction temperature is 80° C., the reaction time is 4 hours, and the stirrer is continuously turned on during the process.

[0062] 5. After the reaction is over, continue to heat up to 100°C, and discharge the water vapor of the reactio...

Embodiment 3

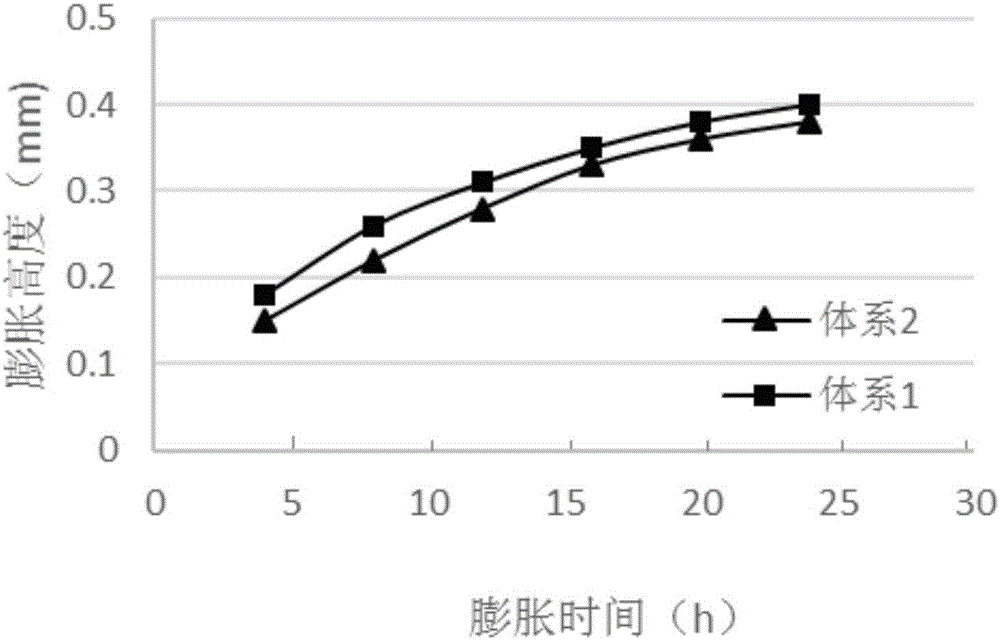

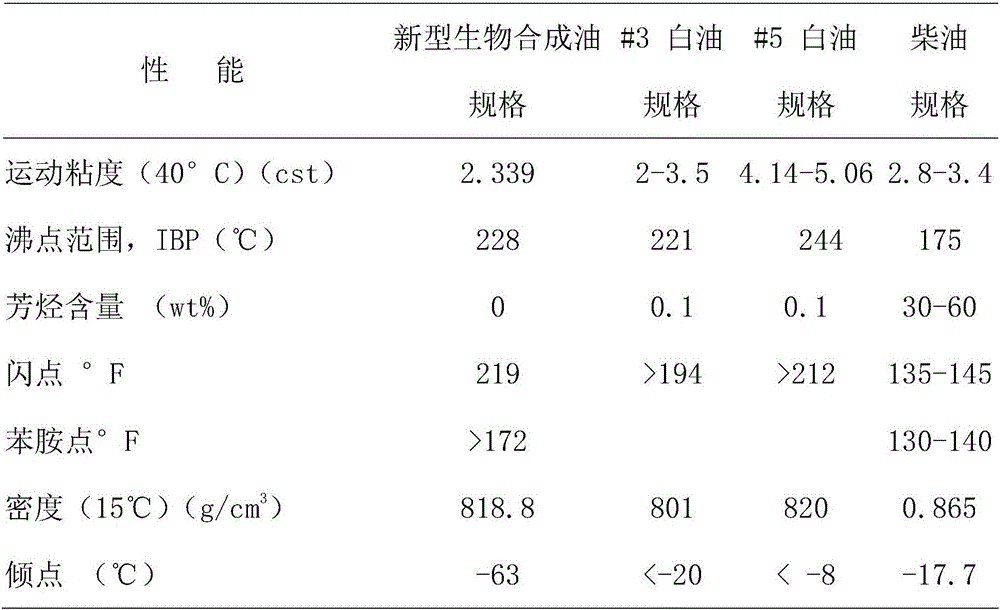

[0069] Preparation and performance comparison of biosynthesis-based environmentally friendly drilling fluid system

[0070] The following percentages refer to volume percentages unless otherwise specified.

[0071] The main emulsifier used in the system preparation is the 4# main emulsifier obtained in Example 1, and the base oil used is the new biosynthetic oil obtained in Example 2.

[0072] (1)1m 3 The formula of biosynthesis-based environmental protection drilling fluid system 1 is:

[0073] 1.5% organic soil; 1.2% primary emulsifier; 2% secondary emulsifier; 1.5% calcium oxide; The volume ratio is 4:1; the rest is barite, aggravated to a density of 2.1g / cm 3 .

[0074] (2)1m 3 The formula of diesel-based drilling fluid system 2 is:

[0075] 1.5% organic soil; 1.2% main emulsifier; 2% secondary emulsifier; 1.5% calcium oxide; 3% fluid loss control agent; diesel oil and calcium chloride brine with a concentration of 30wt%, the volume ratio of the two 4:1; the rest is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com