Temperature-resistant and wear-resistant aluminum plastic alloy and preparation method for conductor covering aluminum plastic alloy

A technology of aluminum-plastic and alloy, which is applied in the manufacture of cables/conductors, plastic/resin/wax insulators, organic insulators, etc. It can solve the problems that the wire outsourcing materials cannot meet the requirements of resistance to temperature and wear resistance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by embodiment the present invention will be further described:

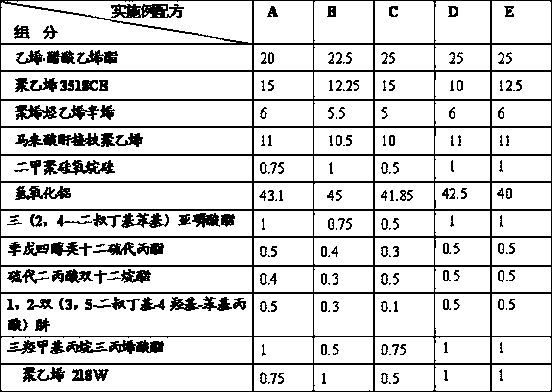

[0018] The temperature-resistant and wear-resistant aluminum-plastic alloy proposed by the present invention is prepared from the following components in weight percent:

[0019] Ethylene vinyl acetate 20.0~25.0%, polyethylene 3518CB 10.0~15.0%, polyolefin ethylene octene 5.0~6.0%,

[0020] Maleic anhydride grafted polyethylene 10.0~11.0%, dimethyl polysiloxane silicon 0.5~1.0%, aluminum hydroxide 40.0~45.0%,

[0021] Tris(2,4-di-tert-butylphenyl)phosphite 0.5~1.0%, pentaerythritol dodecylthiopropyl ester 0.3~0.5%,

[0022] Didodecyl thiodipropionate 0.3~0.5%, 1,2-bis(3,5-di-tert-butyl-4-hydroxy-phenylpropionic acid)hydrazine 0.1~0.5%,

[0023] Trimethylolpropane triacrylate 0.5~1.0%, polyethylene 218W 0.5~1.0%.

[0024] According to needs, described aluminum-plastic alloy can be formulated according to the formula of each embodiment of the following table:

[0025]

[0026] Components of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com