Transmission connecting mechanism device for power takeoff and gear pump

A technology of transmission connection and mechanism device, which is applied in the direction of connection components, machines/engines, key connections, etc., can solve the problems that the transmission shaft is not easy to achieve balance, the concentricity is difficult to meet the requirements, and the gear pump throwing force increases, etc., to achieve Save raw materials, solve the installation position and space, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

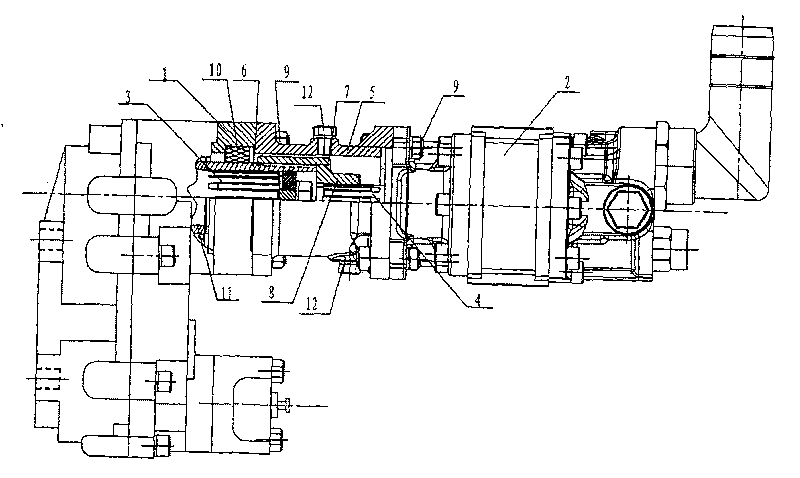

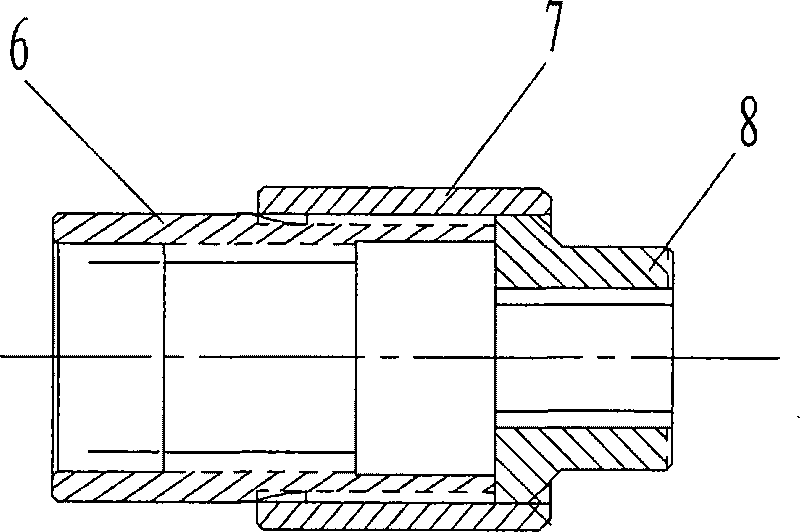

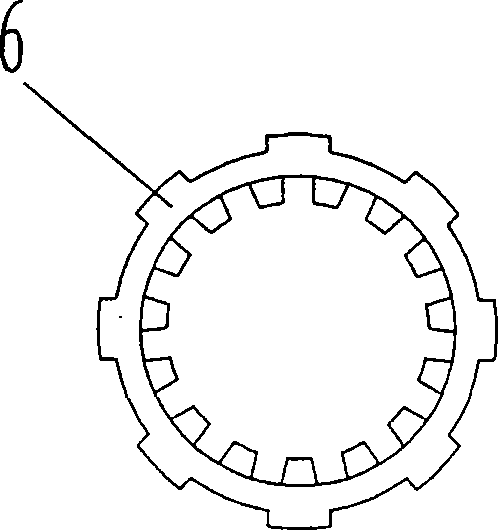

[0022] Embodiment 1: as Figure 1-8 As shown, the power take-off and gear pump transmission connection mechanism device mainly includes a power take-off 1 and a gear pump 2, and the power take-off 1 and the gear pump 2 are connected through a connection mechanism, and the connection mechanism includes a connecting sleeve 5. Spline connection sleeve I 6, spline connection sleeve II 7 and spline connection sleeve III 8, the power take-off 1 and the gear pump 2 are fixed on both ends of the connection jacket 5 by screws 9, and the connection jacket 5 is provided with an oil drain hole 12. The spline shaft 3 of the power take-off device 1 is provided with a spline connection sleeve I 6, and the spline shaft 3 of the power take-off device and the spline connection sleeve I 6 are connected by a spline, and the gear pump spline of the gear pump 2 The key shaft 4 is provided with a spline connection sleeve III8, the spline connection sleeve I 6 and the spline connection sleeve III 8 ...

Embodiment 2

[0023] Embodiment 2: as Figure 9 As shown, a spring 13 can be provided in the spline connection sleeve II7, and the two ends of the spring 13 are in contact with the spline connection sleeve I6 and the spline connection sleeve III8, so that there is a certain buffer force in the working process, and the extension of the parts service life.

[0024] The connecting piece mechanism of the present invention is easy to use, and the splined connecting sleeve can be replaced according to different needs, so as to meet different assembly requirements, and the disassembly and replacement are convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com