Pail floating type power accumulator

A technology of accumulators and floating barrels, which is applied in the direction of machinery and equipment, can solve problems such as damage, deformation, loss, and inconvenient maintenance work, and achieve the effect of light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable your examiners to further understand the structure, features and purposes of the present invention, drawings and preferred embodiments are attached hereto, and the detailed description is as follows.

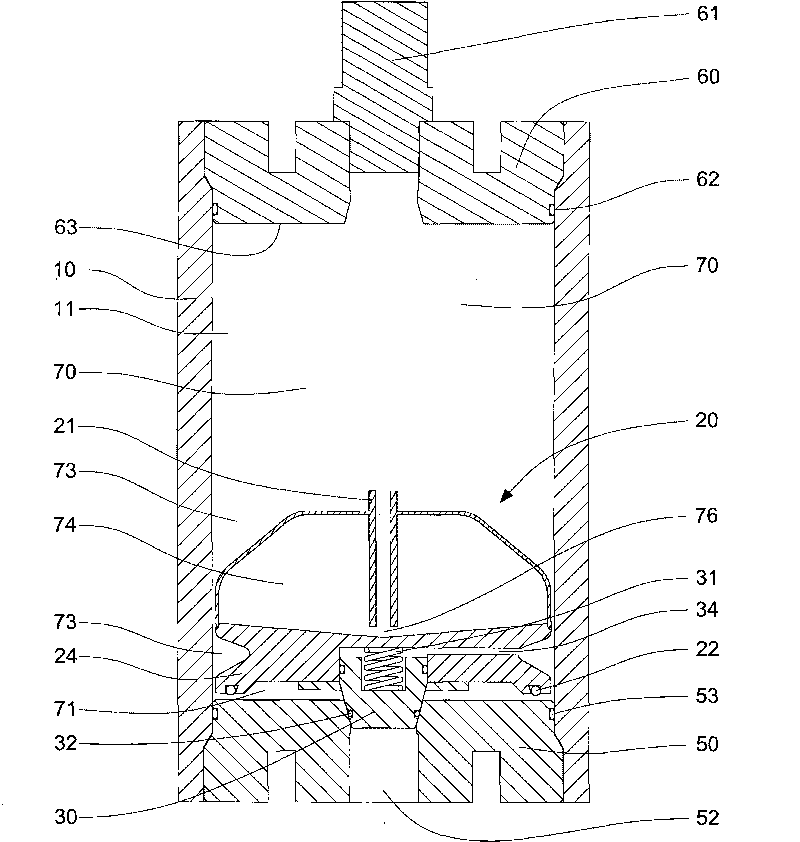

[0031] image 3 It is a schematic diagram showing the structure of the floating bucket type accumulator of the present invention. see image 3 As shown, the floating bucket type accumulator of the present invention includes a casing 10, a floating bucket device 20, a communication pipe 21, an O-ring 22, a floating bucket base 24, a cone valve 30, a pressure-guiding hole 34, a spring 31, an O-ring 32. O-ring 33, lower cover 50, valve seat 51, oil inlet 52, O-ring 53, upper cover 60, inflation valve 61 and O-ring 62. like image 3 As shown, the casing 10, the upper cover 60 and the lower cover 50, the upper cover 60 is provided with an O-ring 62 and the lower cover 50 is provided with an O-ring 53 for sealing; and then they are respectively fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com