Opening circular road whirling premixing upward-spraying backflow preheat burner

A split ring and burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve problems such as low efficiency, unstable combustion, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

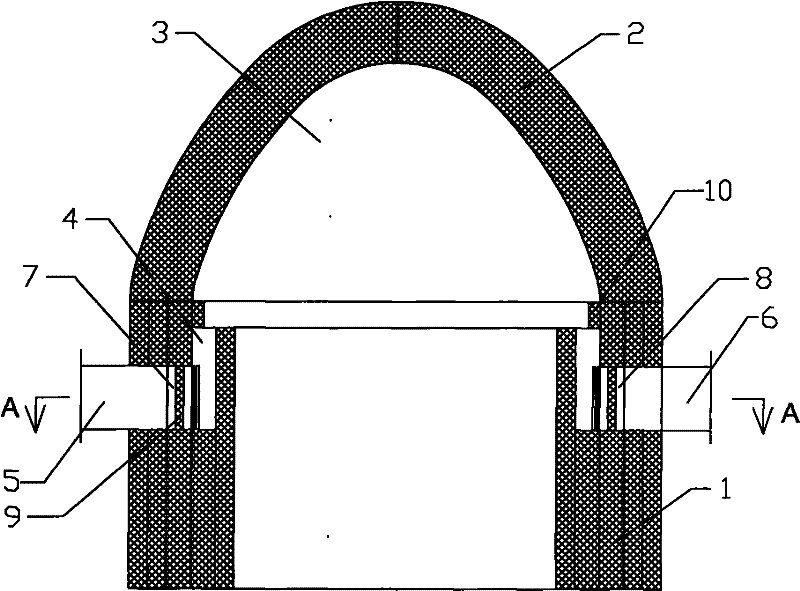

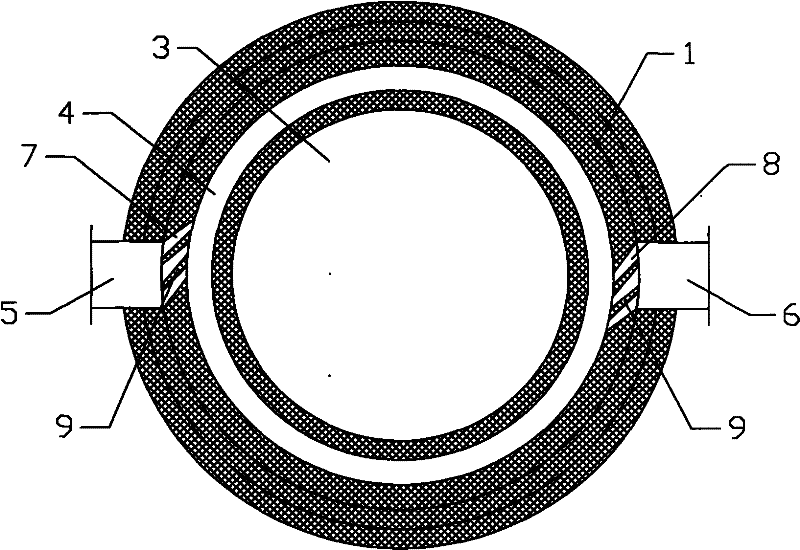

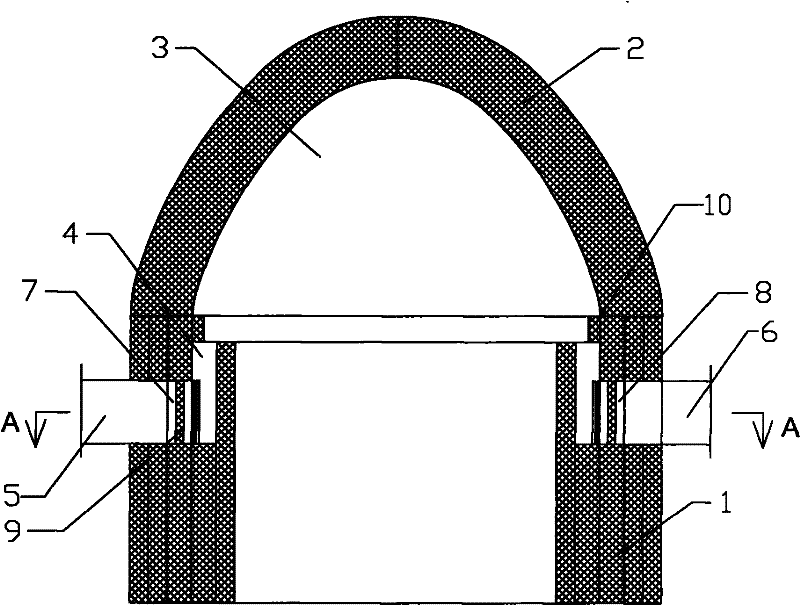

[0006] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0007] Depend on Figure 1-Figure 2 Given, the structure of the present invention is that the cylindrical wall body 1 and the vault 2 on its top form a hemispherical cylinder with the upper end closed and open downwards, and the upper part of the vault is a combustion chamber 3 in the cylindrical wall body, and the cylinder On the inner wall of the wall 1, a premixing ring 4 with an upper opening is arranged in a ring shape. The premixing ring is connected to the gas inlet pipe 5 and the air inlet pipe 6 through the gas diversion channel 7 and the air diversion channel 8 respectively. Flow guide blocks 9 are evenly distributed in the flow channel 7 and the air guide channel 8 , and the upper opening of the premixing ring 4 is connected with a restrictor ring 10 .

[0008] In order to ensure the use effect, the said premixing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com